|

StuccoMetrics® |

Jeff Bowlsby CCS, CCCA

Exterior Wall and Stucco Consultant

Licensed

California Architect

Stucco Building Movement Joint

Subassembly (BMJS)

(“expansion joint” at wall plane)

|

Webpage Quicklinks Terminology: “Expansion Joint vs. BMJS Subassembly Building Structure Substrate

Support Movements Purpose of the BMJS Subassembly BMJS Subassemblies, Water

Intrusion and Water Management Panelized Sheathing over Framing as

Substrate Support Substrate Support Planar

Tolerance and Shims Omission

of BMJS Subassemblies Horizontally-oriented

BMJS Subassembly on Walls Vertically-oriented

BMJS Subassembly on Walls BMJS Intersection with SMJS

subassemblies Sealant at Splices, Terminations,

Intersections Low-Slope

Weather-Exposed Surfaces Detail

Drawings - BMJS Subassembly |

||||||||||||||||||||||||||||||||||||||||||||

|

To

determine which stucco movement joint is appropriate for a given condition,

one must understand the anticipated movement at the condition. Shrinkage and thermal movements occur in the

lath and stucco membrane. BMJS, PMJS

and SMJS each accommodate shrinkage and thermal movements because the lath

and stucco composite membrane is discontinuous through and terminate at each

side of these subassemblies. A SMJS

does not accommodate substrate support movement because the substrate support

is continuous at SMJS. BMJS and PMJS

accommodate substrate support movement because the substrate support is

discontinuous at these subassemblies.

Stucco Movement Joint

Selection Matrix BMJS are not mentioned in the building

code or Minimum Stucco Industry Standards by name, but generically they are

described as “expansion joints”. The

common term stucco “expansion joint” is unfortunately generic, nebulous,

ambiguous, obscure, does not clearly describe that

this is a subassembly and not just a lath accessory, or the function of this

joint subassembly and is rampantly misunderstood throughout the stucco

industry. In search of clarity I

derived and have used the term Building Movement Joint Subassembly (BMJS) as

used on this website for easier recognition and intuitive understanding, and

because it more clearly describes the purpose and function of this stucco

movement joint subassembly. An understanding of the primary

function of the BMJS, the purposes it serves and how it is to function as

presented here, will resolve any lingering debate about its function and how

and where to install it. The BMJS, its intended purpose, function, and installation configuration

can be misunderstood amongst building owners, architects and stucco

craftsmen. If cracking did not occur,

stucco would be much more popular, respected and prolifically used as an

exterior wall cladding. These are the

intended outcomes of these webpages regarding stucco movement joints. Building structure

substrate support movement conditions are

significant factors that if not accommodated, can contribute to stucco

cracking. While building structure substrate movement is

important, it is recognized that other factors can contribute to cracking so

addressing building substrate movement alone, can be considered only one of

many factors contributing to stucco cracking. This webpage focuses

primarily on the issue of building structure substrate movement and methods

to minimize its contributory effects to stucco cracking. Portland cement-based plaster when

cured is a brittle wall cladding material which is not resilient enough to accommodate

building structure substrate support movement. Building structure substrate support

movement joints are designed joints and located to resolve wind, seismic and

other dynamic loading conditions at structural building movement isolation

locations such as seismic joints for large buildings, and at adjacent

property line walls where separate, isolated structural systems adjoin. Building structure substrate support

movement can also occur under normal loading conditions such as at deflecting

beams, at inter-story drift joints of multi-story buildings (using slip

tracks) and sawn lumber floor framing used with wood platform framing, where

the floor framing experiences cross-grain shrinkage. These significant building structure

substrate support movement conditions can contribute to stucco cracks

localized to the area of movement.

While building structure substrate support movement is a significant

condition, it is recognized that many other factors can contribute to

cracking. This webpage focuses on

building structure substrate support movements and methods to mitigate

them. Building Movement Joint

Subassemblies (BMJS) developed from the Perimeter Movement Joint Subassembly

(PMJS), so a complete understanding of the principles presented on the PMJS

webpage is important to understand along with the additional information

presented here. Building structures as a substrate support for

exterior stucco wall cladding systems experience significant structural

system movements that are real and are known causes of stucco cracking. If building structures as a substrate

support did not experience movements such as beam and floor edge deflections,

wind and seismic forces, story drift and similar movements, then there would

be no essential purpose for the BMJS.

This webpage explores the conditions that make the BMJS beneficial to

the success of an exterior stucco wall cladding system on a building as a

substrate support. Visit the StuccoMetrics Reference Archives

webpage for cited references and further information. |

||||||||||||||||||||||||||||||||||||||||||||

|

Mass

masonry and concrete buildings typically do not require building movement

joints in the stucco wall cladding system except where their structure

requires movement joints to isolate known or anticipated building

movements. Where mass masonry or

concrete buildings receive stucco wall cladding, it is often directly applied

and fully bonded to the mass masonry/concrete substrate support. Building movement joints in a mass

masonry/concrete building structure must be accommodated with a similar

movement joint in the stucco wall cladding system to minimize cracking at

substrate support movement conditions. Framed

buildings have experienced stucco cracking from the earliest days when stucco

began to be installed on framed buildings.

Sheathed framing rigidified buildings but cracking continues to

occur. The effects of portland

cement-based plaster shrinkage and thermal movement became better understood

as contributory to cracks in the 1950s

and shrinkage and thermal movement jointing solutions were developed to

address those movements. Contemporary

framed buildings are often continuously sheathed. The sheathing, when it performs a building

structural function stiffens the building to help resist building structural

movement related to wind and earthquake forces. The sheathing, while also performing a

building structural function related to lateral building movement, provides a

more uniform substrate support surface for the stucco wall cladding that is

helpful towards achieving a uniform stucco thickness, which helps minimize

cracking. Framed

building structures whether of metal or wood framing, are often a support

substrate for stucco wall cladding on contemporary buildings. A framed substrate support can contain

components that move, movement that if translated directly to the exterior

stucco wall cladding system, will most certainly cause cracking of the stucco

cladding system. Movements such as

spanning horizontal floor slab edges deflecting over lower walls by way of a

slip track, and sawn lumber floor joints experiencing cross-grain shrinkage,

or building seismic joints separating building sections – all require isolation

from the stucco wall cladding system.

In these conditions the stucco substrate support of the building is

divided into separate adjacent building substrate supports, usually with a

gap, where the gap provides a zone for movement to occur. The stucco wall cladding system is

physically terminated on either side of this gap to accommodate the movement

and to minimize cracking that would otherwise occur if the stucco wall

cladding system were not isolated from the movement zone. Patent research: Not all BMJS lath accessory components and

subassemblies are

patented and not all patented BMJS lath accessory components were produced or are currently available. Select BMJS lath accessory components and subassemblies are discussed.

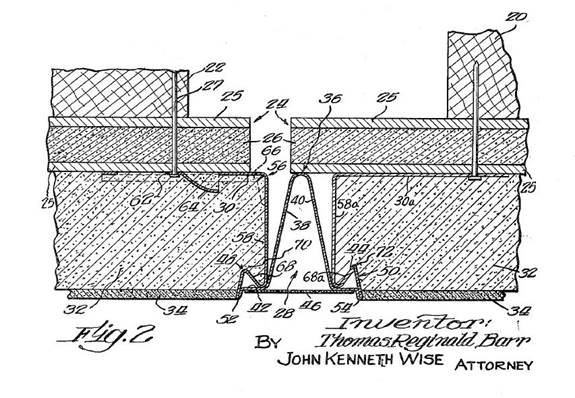

The

1959 Barr design lath accessory and subassembly is on the market today, and

marketed as a “control joint”. In

reality though, it is a BMJS lath accessory and subassembly given the way it

is depicted in its patent illustration, shown with both flanges fastened to a

discontinuous substrate support, although it is not commonly used and its

movement range is limited for this purpose.

1965 Barr design BMJS lath accessory component and subassembly A few years after the Clark “control joint” (SMJS lath

accessory component and subassembly) appeared on the market in the mid-1950s,

Ross Washam brought another stucco movement joint to market in the early

1960s as both a two-piece stucco lath accessory component and subassembly or

Building Movement Joint Subassembly (BMJS), reportedly to accommodate

movements of greater magnitude than what the SMJS lath accessory and

subassembly could accommodate. While

Washam’s patent is dated 1967, it appeared in product catalogs a few years

earlier.

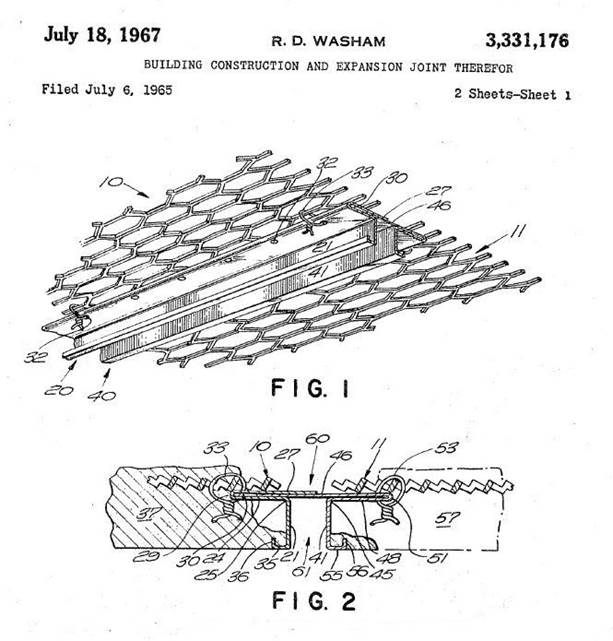

Illustrations from

Washam Patent 3,331,176 (Note

the patent illustrates both a BMJS lath accessory component and BMJS

subassembly. The BMJS lath accessory

is depicted as wire-tied over

discontinuous lath or fastened to the building substrate support) The Clark design and Washam design stucco movement joint lath accessory

components and subassemblies share many similarities: ·

Both were devised

and promoted to minimize stucco cracking of walls and ceilings, at interior

and exterior building locations. ·

Both were

exclusively manufactured and introduced to the market by the Penn Metal

Company (and later by Keene) ·

Both were

illustrated as wire-tied to lath in their patents ·

Both feature paired

ground screeds with a non-plastered gap in between ·

Both patents are

identically titled Building

Construction and Expansion Joint Therefor

even

though filed 10 years apart and by different inventors. ·

Both patents describe the lath

accessory component as an “expansion joint” ·

Both patents are assigned to Penn

Metal Company Inc. and drafted by the same attorneys ·

Both are viable solutions to

minimizing stucco cracking, although from movements of different origins ·

Both are in common use today The

Washam BMJS lath accessory component and subassembly has a familial

resemblance to the Clark design SMJS lath accessory component and subassembly

in that the plaster is terminated at opposite grounds of the lath accessory,

to allow movement between the grounds.

The fact that both the Clark design SMJS and the Washam BMJS were

invented to address portland cement plaster shrinkage and thermal movement in

cement plaster claddings, just with different approaches and solutions, is

interesting and indicative of the significance of the issue of stucco

cracking. With these commonalities it

is not surprising why both the Clark design and Washam stucco movement joint

lath accessory components were referred to interchangeably as “expansion”

joints, “expansion/control” joints, and “expansion and contraction” joints in

product catalogs and by everyone that used them, a blurred terminology which

has contributed to the persistent controversies with stucco movement joints. Take

note of the differences between the Washam lath accessory component from

Clark, which includes discontinuous lath, a variable dimension, determinable

separation gap and grip edge flanges which engage the stucco panel edges to

avoid the separation gap that the Clark design SMJS suffered from then and to

this day. Washam can accommodate

movement in two-directions, whereas Clark can only accommodate one-directional

movement. Note that the patent

illustrations of both Clark and some of the Washam illustrations are not

graphically indicative of any relationship to framing members, the building

structure substrate support (continuous or discontinuous?), fasteners or a

WRB, the lath accessories are simply shown as just wire-tied over the lath

and portrayed in an idealistic free floating condition. This idealism has contributed to the

persistent controversies with stucco movement joints. Since

the mid-1950’s, the Clark design and Washam design

stucco movement joint lath accessory components and subassemblies were the

primary stucco movement jointing solutions available. In 2008 a variation of the Washam lath

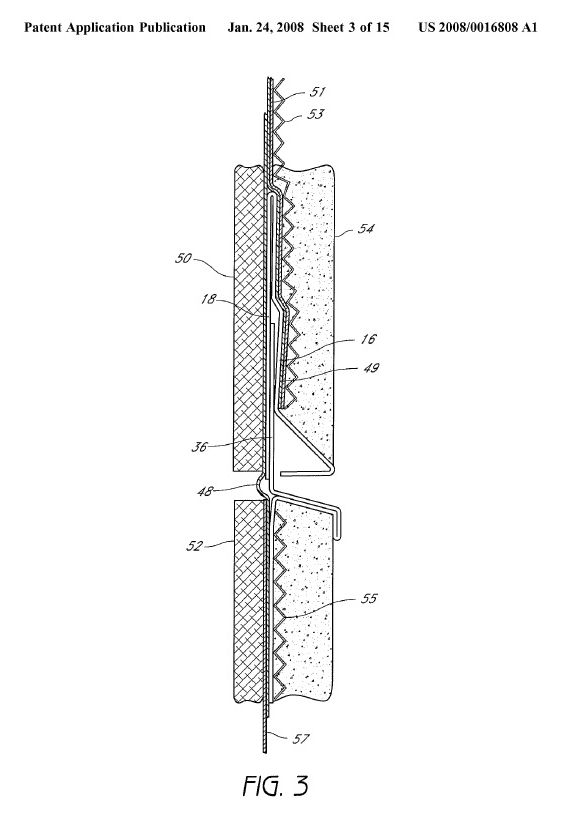

accessory was invented and brought to market by Don Pilz,

which bears a resemblance to the 1972 Conway design “Joint

Construction”. The Pilz

design BMJS lath accessory and subassembly includes a dimensionally-extended

vertical flange for integrating with the WRB and a sloped drainage plane

which is intended to facilitate water drainage for horizontally-oriented

installations on weather exposed building exterior walls. The Pilz

two-piece design BMJS lath accessory and subassembly is intended for

horizontally-oriented exterior wall weather-exposed stucco wall claddings, to

provide drainage as well as significant movement capacity.

Pilz

design two-piece

BMJS lath accessory and subassembly US

Patent 2008/00168080A1 Minimum

Stucco Industry Standards for stucco wall cladding systems are indicated below.

Readers are encouraged to purchase the referenced

ASTM Standards directly from ASTM and review them. The referenced ASTM Standards and texts are

indicated for reader’s convenience, for purposes of topical discussion. Requirements

of the Standards are paraphrased, written in the imperative mood and

streamlined writing format as is recommended by the Construction

Specifications Institute (CSI) and common to construction specifications,

using the terminology developed and described on StuccoMetrics.com. ASTM

C1063 Standard Specification

Installation for Lathing and Furring to Receive Interior and Exterior

Portland Cement-Based Plaster(1): ·

3.2.7 BMJS or PMJS, noun: A movement joint subassembly accommodating

stucco movements that are greater than those associated with plaster

shrinkage and curing. Reference

Specification C926, Annex A2.3.1.2 ·

(7.5.4) 7.5.4 Main runner splices: Nest channel flanges and overlap channel

ends 12-in. (305-mm) minimum. Securely

install ties near splice ends with double loops of either 0.0625-in.

(1.59-mm) or twin strands 0.0475-in. (1.21-mm) galvanized wire. For splices located at BMJS and SMJS,

loosely install ties holding splice together to allow for movement. ·

(7.6.5) Splice main runners and cross furring at

BMJS, SMJS. Reference 7.5.4. ·

(7.10.1.7) Provide BMJS or PMJS with 3/8-in. (9.5-mm)

minimum separation gap where load bearing walls or partitions adjoin

structural walls, columns or floor or roof slabs. Discontinue lath through BMJS or PMJS, cornerite not allowed. ·

(7.11.4.3) Provide BMJS aligned with expansion joint

in substrate support. ·

(A1.2) A1.2 Provide BMJS, PMJS to accommodate

building substrate movement and to minimize movement related stucco and WRB

damage. ASTM

C926 Standard Specification for

Application of Portland Cement-Based Plaster(1: ·

(7.1.5) Apply plaster continuously at walls and

ceilings to avoid cold joints and abrupt appearance changes in each plaster

coat. Abut wet plaster to set plaster

at planar interruptions such as corners, rustications, openings, BMJS, PMJS

and SMJS where possible. Cut joinings,

square and straight, 6-in. (152-mm) minimum away from joining in previous

coat, where they are necessary. ·

(A2.3.1.2) Evaluate the characteristics

of the substrate and indicate the requirements for BMJS, PMJS and SMJS on

construction documents, including type, location, depth, installation

requirements. Install BMJS, PMJS and

SMJS before plastering. ·

(A2.3.1.3) A groove in

plaster is not a BMJS, PMJS or SMJS. ·

(A2.3.3) Provide a BMJS, PMJS or SMJS at transitions

between dissimilar substrate support materials that receive continuous

plaster. ·

(X1.1.6) Indicate the type, location depth and

orientations of BMJS, PMJS and SMJS in the construction documents. ·

(X1.4.2.6) Application of Plaster Basecoats: (1)…lathing accessories used as plaster

thickness screeds include casing beads at stucco panel end and edge

terminations at dissimilar material, BMJS, PMJS and SMJS installed following Specification

C1063,... |

||||||||||||||||||||||||||||||||||||||||||||

|

The

need for “expansion joints” (BMJS lath accessories and subassemblies) has

developed from stucco wall cladding system cracking conditions at transitions

of perimeter substrate support conditions.

In large scale building contemporary construction with substrate

support movement conditions such as multiple stories and drift-deflection

joints, long spans of deflecting floors, and seismic joints, BMJS are an

essential tool for minimizing cracking. Buildings

and parts of buildings experience movement from static and dynamic loading

conditions, movements which require isolation from stucco cladding systems to

minimize cracking. Movements of this

type are localized movements between buildings such as wind and seismic

movements, and portions of buildings such as floor slab edge deflections,

story drift deflections, and sawn lumber cross-grain shrinkage

movements. These movements occur where

they occur and can be locally addressed with BMJS lath accessories and

subassemblies to minimize stucco wall cladding system cracking. As

a point of interest, the Washam stucco movement

joint lath accessory component and subassembly were initially devised and

intended to accommodate stucco shrinkage and thermal movements that were

greater than what the Clark design stucco

movement joint lath accessory component could accommodate. The Clark design and Washam solutions are conceptually similar in their

approach of defining separate isolated adjacent stucco wall cladding panels,

discontinuing the lath and accommodating movement at the location of the

movement joint subassembly. As a two-piece lath accessory component, Washam accommodates

movement by the use of two nested and overlapping sheet metal flanges that are

exposed at the finish surface of the stucco wall cladding system. This

configuration creates an exposed “weather shield” (terminology from the

patent) to cover the separation gap between the adjacent stucco panel edge

grounds, which also protects the concealed WRB from UV exposure. In contrast with the Clark design, the Washam design includes

solid sheet metal flanges, not foraminous flanges, to integrate with the

stucco wall cladding system. Where

lath is used with Washam, the lath accessory component is depicted as

overlaying the lath, over its separate discontinuous lath edges, and is wire

tied to the lath edges. With the Pilz design, lath overlays the solid sheet metal flanges

and fasteners for both the lath accessory and lath are not depicted. The depicted substrate support for both

Washam (lath) and Pilz (wall panel) is depicted as

discontinuous. Because

of the comparatively large dimensional movement requirements for substrate

support related movement joints, as compared to stucco shrinkage movement, a

single-piece building movement joint lath accessory and subassembly is not a

feasible solution. Two-piece BMJS lath

accessory and subassembly joint designs featuring overlapping and nested sections

of a range of dimensions to accommodate substrate support movements. Each piece of the two-piece BMJS lath

accessory includes a stucco panel edge ground which functions not only as a

stucco panel edge termination, but because the lath terminates at the stucco

ground the panel edge function as ½ of a SMJS to accommodate stucco shrinkage

and thermal movements. The

dimensional separation gap between the stucco panel edge grounds is variable

and can be determined based on the amount of anticipated movement

required. This separation gap creates

a recess in the plane of stucco wall cladding that creates an aesthetic

shadow line. The

Washam stucco movement joint lath accessory

component and subassembly is configured with a pair of folded and nested

plates that slip against each other to accommodate movement. The configuration is not inherently

watertight. The Pilz design

stucco movement joint lath accessory component

and subassembly is configured conceptually and functionally similar to Washam

but also includes sloped drainage planar surfaces for facilitating

drainage. The Pilz

design stucco movement joint lath

accessory component and subassembly are intended for horizontally-oriented

installations where drainage is required. The

BMJS lath accessory with integral grounds in either case adds convenience as

an integral stucco thickness screed and location to stop plastering work to

prevent cold joints in the plaster. Minimum

Stucco Industry Standards ASTM C926 and C1063 are

referenced standards in the building code which state minimum installation requirements for BMJS lath accessories and

subassemblies. It is essential to understand that any stucco wall cladding

location with discontinuous lath or where lath terminates at the edge of a

stucco panel, meets the essential functional requirement of a stucco SMJS, a

designated location within the stucco wall cladding system where stucco

shrinkage and thermal movements can occur. The BMJS broadens that functionality by

adding discontinuity of the substrate support to address building structure

substrate support movements. Both the

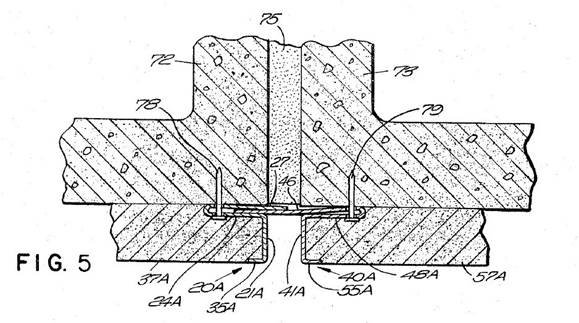

Washam design and Pilz design patent illustrations

depict discontinuity of the substrate support. Washam

depicts that where the BMJS lath accessory component is used with lath that the

solid flanges of the lath accessory overlap and are wire tied to the face of

the lath. Where used at solid bases

such as masonry (see the patent document), the lath accessory is mechanically

fastened to the masonry substrate.

Washam therefore illustrates two different idealized subassembly

configurations where the BMJS lath accessory component is used to both

accommodate movement of the lath and accommodate movement of the substrate

support. Pilz

depicts the lath overlapping the flanges of the lath accessory component. |

||||||||||||||||||||||||||||||||||||||||||||

|

Discussion: Terminology: “Expansion Joint" vs. BMJS Subassembly The term used to describe the stucco “expansion

joint” as a lath accessory and subassembly, has been used, misused,

misunderstood and misapplied throughout the industry. Even its originators did not understand its

applicability in isolating building substrate support movement, although they

did understand its purpose in minimizing stucco wall cladding system

cracking. This website preferentially

uses the term Building Movement Joint Subassembly (BMJS) and BMJS lath

accessory. The two-piece BMJS lath

accessory is used in a BMJS which includes the substrate support (separated

and discontinuous), framing/blocking to fasten both sides of the BMJS lath

accessory and lath edge fasteners, the WRB, the BMJS lath accessory and its

fasteners, the configuration of the lath (discontinuous), and of course the

portland cement-based plaster. Discussion: Building Structure Substrate Support

Movements By the mid 1950’s initial stucco shrinkage during curing and

thermal movements while in service

were recognized causes of cracks and the Clark design one-piece stucco SMJS

component and subassembly was brought to market as a more convenient form of

the jobsite fabricated, two-casing bead SMJS.

The Washam design BMJS lath accessory and subassembly was devised and

effective for the same purposes, but its greater movement potential has been

found to be more beneficial for accommodating building structure substrate

support movements. Framed building

structure substrate supports especially with regards to larger scale

buildings, often include substrate support movement conditions that must be

managed where occurring under stucco wall claddings, or cracking will

occur. Spanning beams and floor slab

edges deflect relative to the walls below them, seismic joints vertically and

horizontally allow movement to occur between sections of building structures

and story drift joints at building stories slide past each other to

accommodate lateral movement building deflections to occur whose dimensional

movement can be significant. Only

two-piece BMJS are currently capable of the required dimensional extent and

directionality of movement these conditions require. Discussion:

Purpose of the BMJS Subassembly As

the SMJS is related to movement of the lath, the BMJS is related to movement

of the substrate support. It is

interesting to note that the lath terminates at both SMJS and BMJS, and as a

result both are capable of accommodating stucco wall cladding shrinkage and

thermal movements, even though that is not the primary purpose of a BMJS. To

accommodate stucco wall cladding shrinkage and thermal movement the SMJS lath

accessory is wire-tied only to the lath which is discontinuous to allow the

greatest stucco wall cladding movement, and the substrate support is

continuous because the movement is related to the stucco cladding, not the

substrate. In contrast, to accommodate

building structure substrate support movement the BMJS lath accessory

component is attached only to the separate building structure substrate

supports which are separated and discontinuous to allow the greatest movement

between the separate building structure substrate supports. Building structures and materials are exposed to and

must accommodate various structural and physical forces and their related

deflections or movements to function as expected. Gravity loads cause

vertical building movements such as beam and floor slab edge

deflections. Wind and seismic loads

cause lateral building movements such as inter-story drift. Stucco, as one of the few exterior wall

cladding materials applied as a wet material, experiences shrinkage movement

as the stucco cures. Daily and

seasonal ambient thermal variations cause expansion and contraction movements

within all building construction materials.

Each of these movements must be accommodated in some way or the

building and its cladding material will not function as anticipated. Building structural movements, expressed either

vertically or laterally, as a substrate support for stucco, are accommodated

with BMJS or PMJS. Portland

cement-based shrinkage and thermal movements are accommodated with SMJS. BMJS and PMJS also accommodate shrinkage

and thermal movements because the lath is not continuous through these

joints, but shrinkage movements and thermal movements are not the primary

function of BMJS and PMJS. Isolating stucco wall cladding panels

using BMJS located in certain locations where substrate support movement occurs

such as where floor slab edges deflect or where the substrate support systems

change, configured in a certain way to accommodate this differential

movement, sealed at critical junctures to effectively manage the effects of

water, create a Building Movement Joint Assembly that minimizes

cracking. The Assembly is the sum of

its parts, arranged and functioning together to serve the purpose of

minimizing cracking. No singular BMJS

lath accessory component or BMJS subassembly in isolation can accomplish the

effect of the Assembly as a whole on the stucco wall cladding system. Building Movement Joint Subassemblies (BMJS) serve these purposes: ·

1st Purpose: Accommodates building structure substrate

support movements because the substrate support is discontinuous. Accommodates portland cement-based plaster

shrinkage movement, because the lath is discontinuous. ·

2nd Purpose: As a ground screed to gauge the application

thickness of portland cement-based plaster to assist in the achievement of its

intended nominal thickness and finish planarity. ·

3rd Purpose: Segments and panelizes continuous stucco

wall cladding assemblies into functionally isolated, discrete, smaller,

adjacent wall cladding panel areas with panel edges that define portland cement-based

plaster work stoppage locations and prevent cold joints. Discussion: BMJS Subassemblies, Water Intrusion and

Water Management Bulk

water can potentially intrude into and behind the exterior stucco wall

cladding at unsealed gaps at stucco panel perimeters and penetrations, at

exposed lath accessories such as splices, terminations and intersections of

casing beads, stucco movement joints, at unsealed drainage flashing laps and

at anomalous construction conditions.

Exterior stucco wall claddings installed over a continuous WRB and

drainage flashing system integrated watertight with adjacent wall components

is a drainage wall assembly, and dependent on the performance characteristics

and workmanship of the WRB and drainage flashing system, the exterior stucco

wall cladding system can accept and manage bulk water. A concern with BMJS amongst waterproofing professionals is bulk

water intrusion at unsealed gaps at exposed lath accessories primarily at the

finish stucco surface of corners, intersections, end terminations and butted

termination splices. Splice plates and

end caps that can be sealed watertight are not available for any BMJS lath

accessory. At weather-exposed surfaces

these conditions should be sealed watertight at the stucco surface to

minimize bulk water intrusion behind the stucco cladding system, by embedding

the condition in a sealant bed from behind as the lath accessory is

installed. BMJS

are hollow profile sections that function as

water collection channels and that divert water wherever it will go,

concealed behind the lath accessory. Butted termination splices of adjacent BMJS terminations,

unsealed and occurring along stucco panel edges are problematic because they

can cause perpendicular splice cracking which appear unsightly and can allow

water intrusion. Butted termination

splice cracking can be avoided by limiting a stucco panel edge to 10 ft.

(length of a BMJS lath accessory without splices) or less and not allowing a

butted termination splice to occur along a stucco panel edge, by locating

termination splices only at BMJS lath accessory intersections where a crack

is not possible. The potential for

water intrusion at butted splice terminations can be minimized by embedding

the lath accessory terminations at the splice location in a sealant bed. A

recent variant to the Washam design BMJS lath accessory has been developed

with a drainage surface (Pilz, 2008) to provide

drainage capability for horizontally-oriented BMJS installations on walls by

providing a solid sheet metal flange as an upward-oriented flange which

integrates with the WRB and flashings.

Coordinate the locations of butted termination splices of the Pilz design Horizontal

Drainage BMJS lath accessory at intersections with vertical stucco

movement joint subassemblies, to avoid perpendicular butted termination

splice cracking. A continuous framing or blocking substrate support member is required at

BMJS for fastening the BMJS lath accessory component to the building

structure substrate support and the adjacent discontinuous lath edges at the

BMJS location. Often the typical

framing already present is sufficient. Discussion: Panelized Sheathing over Framing as

Substrate Support BMJS accommodate building substrate support

movements. A gap or discontinuity in the substrate support to accommodate

movement is required and essential for a BMJS to function. Discussion: Substrate Support Planar Tolerance and

Shims It is an all-too-common

occurrence that wall assembly structures as substrate support for stucco, are

sometimes built beyond acceptable planar tolerance resulting from a variety

of circumstances, but at the same time, finish planarity tolerances for

stucco wall cladding systems are still required. So one question is, can and should BMJS, in

their function as screeds for thickness control, be shimmed to achieve

acceptable finish surface alignment?

Succinctly no, for multiple reasons.

BMJS lath accessories should not be shimmed and the need to shim

indicates problematic substrate issues that require resolution independent

from the stucco wall cladding installation to avoid stucco cladding system

performance problems: ·

Shimming BMJS lath

accessories is not a recognized lath or lath accessory installation method in

ASTM C1063 which requires a substrate within planar tolerance by reasonable

inference. ·

Shimming BMJS lath

accessories is not recognized or discussed in SMJS lath accessory

manufacturer’s product literature. ·

Shimming BMJS lath

accessories may create excessive differential stucco thickness variations and

may allow wet portland cement-based plaster mortar migration behind the BMJS

lath accessory, which can cause cracking. ·

Shimming BMJS lath

accessories causes fastener penetrations through the WRB that are often not

in compression to the WRB, potentially allowing water intrusion.

BMJS Substrate Support

condition exceeding planarity tolerance (Install

framing within planarity tolerance or

shim lower sheathing panel to meet planarity tolerance) Discussion: BMJS Lath Accessories The

two BMJS lath accessories available on the market today share many

similarities in that they are of a two-piece design of rigid materials and

require a physical gap to perform their function. The

Washam design BMJS lath accessory and subassembly is only appropriate for

vertically-oriented applications on walls because its drainage capability is

along its length. The

Pilz design BMJS lath accessory and subassembly is

most appropriate for horizontally-oriented applications on weather-exposed

exterior walls because of its sloped drainage surface. This configuration requires the WRB to

overlap the Pilz PMJS lath accessory to function as

a drainage screed flashing. Materials: BMJS lath

accessories are available in galvanized steel, solid zinc alloy, stainless

steel sheet metals and extruded PVC.

Not all BMJS lath accessories are available in all materials from

every manufacturer. BMJS lath

accessories and adjacent lathing materials and fasteners must be carefully

selected for material compatibility. Consider that materials such as

stainless steel and galvanized steel/solid zinc alloy are at opposite ends of

the galvanic scale and may corrode if used together. Galvanic action is possible with galvanized

steel or solid zinc alloy materials in a shared environment with stainless

steel in the presence of water. ·

Galvanized steel

sheet metal: The most common BMJS lath

accessory material used in most regions throughout the USA. Typically G60 galvanization but G90 may be

available from select manufacturers. ·

Solid zinc alloy

sheet metal: Several manufacturers

recommend solid zinc alloy BMJS lath accessories for all exterior building

locations as a precaution against corrosion.

Solid zinc alloy has 2x the movement capability of galvanized steel as

a SMJS lath accessory. Zinc

BMJS lath accessories cost more than galvanized or PVC to both purchase and

install as a result of its inherent

flexibility. Solid zinc and PVC lath

accessories with larger dimensions of material exposure are subject to

extreme thermal movements.

Solid zinc alloy BMJS subassemblies with larger dimensions of material exposure ·

Extruded Polyvinyl

Chloride (PVC): Lowest cost and

offering excellent corrosion protection, PVC BMJS lath accessories are primarily

used at coastal and corrosive environments where corrosion protection is

essential.

PVC BMJS lath accessories. More

expensive to install than galvanized steel resulting from its flexibility. ·

Stainless steel

sheet metal: Available in both 304 and

316 stainless steel, these materials have excellent corrosion resistance. Two

different generic BMJS lath accessory profiles are available in the

marketplace today with variations of materials, ground dimensions and

manufacturer. It is reasonable to

suggest that none of the BMJS lath accessory products available on the market

are ideal solutions, although if utilized correctly they can be effective within

their individual limitations and are the best solutions currently

available. All are made of reasonably

corrosion-resistant materials, but if their installed location is in a marine

or corrosive environment, avoiding galvanized steel is beneficial. Profiled splice plates and end caps for sealing

splices, intersections and terminations are not available for any BMJS lath

accessory profile from any manufacturer, setting the condition in a sealant

bed is the primary solution to seal these conditions watertight. Hollow-profile BMJS lath accessories can

function as water channels and drainage must be considered in their use and

installation. No stucco industry product standard exists that specifies the

engineering technical aspects of the BMJS lath accessory and no two

manufacturers make them identically, so a BMJS lath accessory is technically

not a generic lath accessory conforming to a generic industry standard. BMJS lath accessory engineering technical information, including performance

testing characteristics when assembled as BMJS subassemblies, are not

typically published or available from their manufacturers. The lack of complete engineering technical

information about BMJS lath accessory products, adds to the challenges for

designers and installers to accurately know how and where to use the BMJS

lath accessory or how and where to integrate the lath accessory into exterior

stucco wall cladding subassemblies for greatest effectiveness. BMJS lath accessory manufacturers are

encouraged to either develop a common industry product and installation

standard and conform to it, or at least provide complete engineering

documentation indicating all physical dimensions, materials, splicing

methods, termination and intersection methods, movement capabilities and

limitations of the BMJS lath accessory as installed in a BMJS subassembly,

and the correlating installation requirements for design and installation

reference. Discussion: Omission of BMJS Subassemblies Mass masonry or solid concrete buildings from

previous eras often do not have building structure substrate support joints

of any kind because they are solid and monolithic and that results in a

certain architectural aesthetic that many find attractive. Contemporary mass masonry or solid concrete

buildings use masonry and solid concrete differently than in earlier times

and most if not all do require and have substrate support joints to

accommodate building structure movements that are the substrate support for

stucco wall claddings. Framed building

structures also include building structure substrate support joints to

accommodate movement at conditions such as floor slab edges of multi-story

buildings, seismic joints, inter-story drift joints etc. Minimum Stucco Industry Standard ASTM C1063

requires a BMJS to be located within the stucco wall cladding system proximate

to building structure substrate support movement joints to minimize cracks in

the stucco wall cladding system.

Omission of BMJS in the stucco wall cladding system at building

structure substrate support movement joints promotes cracking localized to the

omitted substrate support joint condition and does not comply with ASTM

C1063. Complete

omission of BMJS to achieve a monolithic aesthetic also deprives the stucco

craftsman of the thickness screed (gauge) and work stoppage functions that

BMJS provide. Without BMJS the stucco

craftsman loses an important quality control tool that is useful in applying

plaster to a uniform nominal thickness and a place to stop work for the day

without creating a cold joint, both conditions of which may cause cracking. Discussion: Discontinuous Lath The

Washam design and Pilz design BMJS lath accessory components

include solid sheet metal flanges for mounting. The Washam patent illustration depicts the solid

flanges of the lath accessory component overlapping the lath, a condition

that is well-known to cause a linear stucco crack from the differential

substrate as the stucco sees it. In

both the Washam design and Pilz design lath accessories, lath must overlap

the solid flanges of these subassemblies to minimize stucco cracking at the

edge of the solid flange. BMJS

lath accessory components include integral stucco termination grounds which

create stucco panel perimeter edges.

Lath terminates at these termination grounds and is discontinuous

through the BMJS. While a BMJS exists

to address building structure substrate movements, it also minimizes portland

cement-based plaster shrinkage and thermal movements, to minimize stucco

cracking. The

BMJS is related to movement of the substrate support,

and the BMJS lath accessory has solid flanges. Potential fastener types used for BMJS

include nails, screws, staples, wire ties, and concrete fasteners. Fastener type selection is based on BMJS

functional requirements for materials to be joined, and substrate support

material characteristics. ·

Joining BMJS lath

accessory flanges to suspended steel grillage substrate support without sheathing

requires wire ties or screws. ·

Joining BMJS lath

accessory flanges to wood framed or furred substrate supports with or without

sheathing requires nails, screws, or staples. ·

Joining BMJS lath

accessory flanges to steel framed or furred substrate supports with or

without sheathing requires screws. ·

Joining BMJS lath

accessory flanges to solid plaster base substrate support, mass masonry or

solid concrete, requires concrete fasteners. BMJS

lath accessory fasteners may impact the function of BMJS, yet fastener type,

sizes, spacing etc. are seldom indicated in lath accessory manufacturer’s

literature, or on construction documents. Discussion: BMJS Subassembly Locations Because

the BMJS is subservient to substrate support movement, it needs to be located

proximate to the substrate support movement condition. Movement conditions at the building

structure substrate support determine the location for BMJS. A BMJS has no functional purpose to

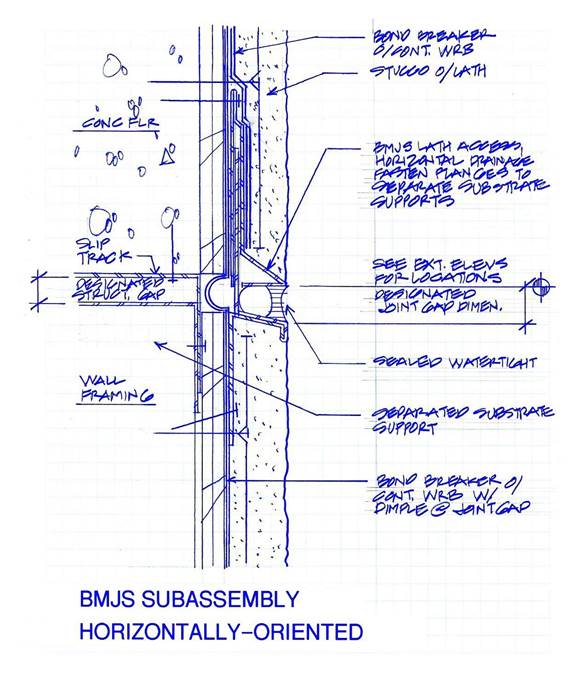

accommodate movement when used in other locations. Discussion: Horizontally-oriented BMJS Subassembly on

Walls BMJS

in horizontal orientations on weather-exposed exterior building walls are

subject to wind driven water exposure.

The Pilz BMJS lath accessory and subassembly

includes an extended flashing flange to integrate with the WRB, and a sloped

drainage surface, where the Washam design does not. BMJS

lath accessories are manufactured in 10 feet lengths and may be required and

located continuously around buildings with long wall lengths such as for interstory drift joints or floor slab edge deflection

joints on multistory buildings. BMJS

lath accessory component splices along panel edges can contribute to

localized splice termination cracking and water intrusion. Splice plates are not available for BMJS

lath accessories. Butt splices of

horizontally-oriented BMJS can be embedded in sealant and located at sealed

intersections with other exposed lath accessories to minimize splice

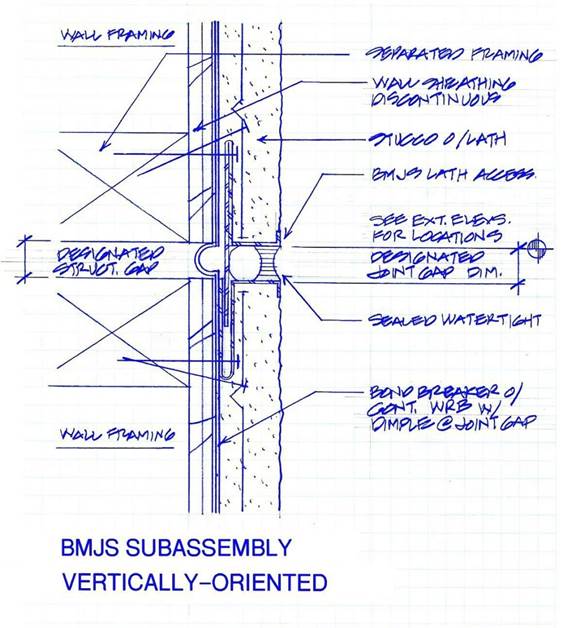

termination cracking and to minimize water penetration. Discussion:

Vertically-oriented BMJS Subassembly on Walls BMJS

in vertical orientations on weather-exposed exterior building walls are

subject to wind driven water exposure.

The Washam design BMJS lath accessory and subassembly can simply be

placed over the WRB and does not require to integrate

with it for drainage which can occur vertically down its length. BMJS

lath accessories are manufactured in 10 feet lengths and may be required and

located to extend vertically up buildings such as for seismic joints between

adjacent sections of large buildings.

BMJS lath accessory component splices along panel edges can contribute

to localized splice termination cracking and water intrusion. Splice plates are not available for BMJS

lath accessories. Butt splices of

horizontally-oriented BMJS can be embedded in sealant and located at sealed

intersections with other exposed lath accessories to minimize splice

termination cracking and minimize water penetration. Discussion: BMJS Intersections with SMJS subassemblies BMJS accommodate building structure substrate support movements. SMJS accommodate stucco wall cladding

shrinkage and thermal movement joints that are significantly smaller than the

BMJS movements. At intersections of BMJS and SMJS, the BMJS must be

continuous through the intersection because the potential movement is

greater. (2) Discussion:

Sealant at Splices, Terminations, Intersections The

Washam design BMJS when installed on ceilings and soffits presents one usage

condition, often non-weather exposed conditions. But what about when this lath accessory

component and subassembly is on a weather-exposed building exterior

wall? How does it function when it is

vertically oriented on a wall or when it is horizontally-oriented on a wall

and are the two conditions the same or different? One of the objectives of the Washam design

BMJS lath accessory and

subassembly as stated in the patent was to “maintain the integrity of the

weather shield while still permitting variations in the widths of the gaps

between the plaster sections over wide ranges.” The method to accomplish that uses folded,

nested, exposed sheet metal plates that protected the concealed WRB from

ultraviolet exposure. The folded and

nested plate configuration of the BMJS lath accessory however is not

watertight if not sealed, especially where mounted in a horizontally-oriented

position on an exterior building weather-exposed wall. Water can readily bypass around the

articulated and nested folds and can penetrate behind the lath accessory if

the separation gap is not sealed.

Further, the BMJS lath accessory component like most lath

accessory components is only produced in 10 ft long

sections, which requires splices when longer lengths are required and it must

often be installed at building interior and exterior corners. Splice and corner conditions are often

simply square cut or mitered and end butted together. Though potentially sealed with sealant they

are difficult to make water tight, in part because splice plates and factory

manufactured prefabricated corners for two-piece joint accessories are not

often available. Where the Washam

design BMJS is installed in a horizontally-oriented position on a building

exterior weather-exposed wall, it must address water drainage either over its

mounting flanges or behind them, either of which problematic.

Vertically-oriented installations are not as concerning in terms of a water

management function, as long as the separation gap is sealed watertight. Sealing the separation gap of the

Washam design BMJS lath accessory is essential. Sealing the separation gap of the Pilz design BMJS lath accessory is advisable. Sealing BMJS splices, terminations and

intersections is essential to minimizing water penetration into the stucco

wall cladding assembly which is the most effective method of managing wind

driven water exposure – minimize its entrance into the wall assembly. Sealant at vertical BMJS above and

intersecting drainage screeds or flashings must be installed carefully to not

impede drainage. Discussion: Low-Slope Weather-Exposed Surfaces Exterior stucco wall cladding systems installed on low slope

surfaces are not an optimum solution from a stucco durability and

waterproofing perspective.

Weather-exposed, stucco clad surfaces less than 60 degrees from

horizontal can be considered as roofs in the building code by reasonable

inference and it is recognized that roof surfaces are exposed to

environmental conditions much more extreme than vertical and near vertical

walls. Stucco is a wall cladding

system, not a roofing system or material, and is not an optimum solution for

low slope, weather-exposed surface conditions. Wall cap surfaces such as

at parapets, balcony railing walls and fences are oftentimes long narrow

surfaces that exceed stucco panel area geometry proportion limitations, and

cracking is more prevalent in this condition, which are potential water

intrusion conditions. Stucco cladding

movement joints that continue up from the wall below are especially

problematic from a water intrusion perspective. The best technical solution is to provide durable materials appropriate

for these conditions such as sheet metal copings, drainage and a concealed

waterproofing membrane, which eliminates the need for BMJS on low-slope

weather-exposed conditions. Discussion: Ornamental Features Decorative ornamental

feature elements as components of a stucco wall cladding system are often

adhered to the brown coat for ornamental purposes. BMJS open and close with building structure

substrate support movements and restricting these movements with continuous

overlaying ornamental features may result in cracking in the less forgiving

material, usually in the element spanning over and attached to both sides of

the BMJS, or occasionally the adjacent localized stucco cladding and finish

coat. Terminating decorative ornamental feature materials at either

side of the BMJS so that movement is free to occur preserves the

functionality of the BMJS. Where

visual continuity is desired consider using resilient sealant of appropriate

color, over backer rod to span the gap over the BMJS. Use

of BMJS, even conservatively, cannot guarantee against cracking. Restraints of the BMJS lath accessory itself: Even when correctly installed, the BMJS

lath accessory may restrain building structure substrate support movement

somewhat, especially when sealed.

Sealant-based joints may be limited in range of movement by the

characteristics of the sealant and configuration of the sealant joint. BMJS

lath accessories, subassemblies and assemblies using their current one-piece

design, subassembly and assembly configuration, as with all things, have

limitations in performance even when configured optimally. In spite of these limitations, they are the

best BMJS lath accessory, subassembly and assembly solution we have available

and we simply need to understand their capabilities and limitations and use

them appropriately. BMJS lath

accessory, subassembly and assembly limitations include: ·

No range of ground depth

adjustability to resolve substrate support planarity tolerance conditions,

without using shims ·

Nested and folded (hollow) BMJS

lath accessory profile functions as water conduit ·

Profiled splice plates are not

available and BMJS lath accessory material in section is cumbersome to seal

watertight at terminations, splices, intersections without embedment using a

thick sealant daub as setting bed. |

||||||||||||||||||||||||||||||||||||||||||||

|

Conclusions: Terminology: “Expansion Joint" vs. BMJS Subassembly The term “expansion joint” is too

nebulous to be meaningful, does not describe its function, does

not make the important distinction between the joint subassembly and the lath

accessory. Building Movement Joint

Subassembly (BMJS) and BMJS lath accessory are more descriptive and useful

and are used on this website. Conclusions: Building Structure Substrate Support

Movements Building

structure substrate support movements are significant and if not effectively

accommodated, can cause cracking. Conclusions: Purpose of the BMJS Subassembly The BMJS functions to accommodate building

structure substrate support movements, functions as a plaster thickness gauge

and convenient working edge to minimize cracking. Conclusions: BMJS Subassemblies, Water Intrusion and

Water Management Wrinkling of a WRB caused by moisture

absorption can cause cracking. Bulk

water intrusion at BMJS is a concern of building enclosure performance that

can be minimized with sealants applied in strategic locations and conditions

before plastering. Drainage flashings

provide a means of drainage to manage bulk water that does penetrate into the

exterior stucco wall cladding system. Framing/blocking at BMJS on framed or framed and sheathed walls is required for fasteners. Conclusions: Panelized Sheathing over Framing as

Substrate Support Sheathing panels such as wood-based plywood and OSB, and gypsum-based sheathing panels are common and beneficial to exterior stucco wall cladding to assist with attaining uniform thickness. Panelized sheathing as a substrate support for exterior stucco wall cladding is required to be discontinuous at BMJS. Conclusions: Substrate Support Planar Tolerance and

Shims Substrate support planarity tolerances

are important if not critical, to providing an acceptable substrate for

lathing and plastering, and to avoid shimming lath accessories. Localized offsets in planarity should be eliminated or

minimized to minimize stucco cracking. Conclusions: BMJS Lath Accessories Two BMJS lath accessories exist to

accommodate building structure substrate support movements, and one functions

as a horizontal drainage screed. Galvanized

steel BMJS lath accessories may corrode under corrosive environmental

conditions, which may require

solid zinc alloy, stainless steel or PVC BMJS lath accessory materials at corrosive environments. Larger dimension solid zinc and PVC BMJS

lath accessories are subject to extreme thermal movements. Manufacturers of BMJS lath accessory

components do not publish complete technical specifications of their BMJS

products Conclusions:

Omission of BMJS Subassemblies The desirable monolithic aesthetic of stucco

on a mass masonry or solid concrete substrate is functionally incompatible

with a stucco and lath composite on a framed or framed and sheathed substrate

support. BMJS provide important quality control functions

related to minimizing stucco cracking, to a stucco wall cladding system on a

framed or framed and sheathed substrate support. Conclusions: Discontinuous Lath Discontinuous lath at BMJS is required by ASTM C1063, to accommodate building structure substrate support movements, which minimizes stucco cracking. Fasteners appropriate to the substrate support are used to fasten BMJS to the substrate support. BMJS lath accessories are fastened to the building structure substrate support to maximize BMJS movement and minimize stucco cracking. Conclusions: BMJS

Subassembly Locations BMJS

location requirements provide minimum accommodation for minimizing stucco

cracking related to building structure substrate support movement. Conclusions: Horizontally-oriented

BMJS Subassembly on Walls Horizontally-oriented BMJS at exterior

building weather-exposed walls require a drainage function. Butt splice termination cracking must be

considered when determining BMJS splice locations. Conclusions:

Vertically-oriented BMJS Subassembly on Walls Vertically-oriented BMJS at exterior

building weather-exposed locations, may be placed

over the continuous WRB. Butt splice

termination cracking must be considered when determining BMJS splice

locations. Conclusions: BMJS Intersections with SMJS subassemblies Both BMJS and SMJS are stucco movement joints with

the BMJS accommodating greater dimensional movement. At intersections of BMJS and SMJS, the BMJS must be

continuous through the intersection. Conclusions: Sealant at Splices, Terminations,

Intersections Seal

BMJS butt splices, terminations and intersections watertight by setting the

condition in a sealant daub during installation, to minimize bulk water

intrusion behind the stucco wall cladding and protect the sealant from

ultraviolet light deterioration. Omit

sealant at the base of vertically-oriented BMJS, where above horizontal

drainage screeds or flashings, to promote drainage. Conclusions: Low-Slope Weather-Exposed Surfaces Providing stucco cladding and BMJS on low-slope weather-exposed surfaces (less than 60 degrees from vertical) without specialized materials and detailing is not an optimum solution from a stucco durability and waterproofing perspective. The best technical solution is to avoid stucco wall cladding systems at this condition and provide roofing materials and concealed waterproofing at low-slope weather-exposed exterior surfaces. Conclusions: Ornamental Features Avoid

installing ornamental features that span over both sides of a BMJS to avoid

localized stucco cracking. Recognize and accommodate the performance limitations of the BMJS lath accessory and BMJS subassembly in stucco wall cladding systems, for maximum performance towards minimizing stucco cracking and bulk water intrusion. |

||||||||||||||||||||||||||||||||||||||||||||

|

Suggestions: Terminology: “Expansion Joint" vs. BMJS Subassembly Minimum

Stucco Industry Standard: “Expansion joint” is the term currently

used in Minimum Stucco Industry Standards. Stucco

Best Practice: The terms Building Movement Joint

Subassembly (BMJS) and Building Movement Joint lath accessory make an

important distinction between the two similar terms, and should be used to

replace “expansion joint”, as more accurate and descriptive terms, in their

appropriate contexts. Suggestions: Building Structure Substrate Support

Movements Minimum Stucco Industry Standard: Recognize that building structure substrate support movements are significant and if not effectively accommodated, can cause cracking. BMJS effectively specified, located, detailed and installed can minimize stucco cracking. Suggestions: Purpose of the BMJS Subassembly Minimum

Stucco Industry Standard: Recognize that the BMJS is useful to

accommodate building structure substrate support movements, is a convenient

exterior stucco wall cladding subassembly to assist in achieving required

plaster thickness and planarity within tolerance, and a convenient location

to stop plastering work to avoid cold joints and related cracking. Suggestions: BMJS Subassemblies, Water Intrusion and

Water Management Minimum

Stucco Industry Standard: Recognize that the

building code and Minimum Stucco Industry Standards, as well as a long list

of voluntary industry standards and references from throughout the stucco

industry, require and recommend sealant or caulking at unsealed gaps such as at exposed lath accessory

perimeter panel edges, mitered corners, intersections, end terminations and

butted termination splices, to prevent entry of water. Stucco

Best Practice: Provide WRB materials that provide drainage that

do not absorb moisture to avoid WRB wrinkles that may cause cracking. Minimum Stucco Industry Standard: Framing or blocking in

addition to regular framing members may be needed at BMJS locations on walls

to receive fasteners. ASTM C1007

requires framing or blocking for steel stud framed assemblies. Necessary framing or blocking to receive

lath edge fasteners at BMJS should be indicated in the construction documents

by the design authority for all substrate support conditions. Suggestions: Panelized Sheathing over Framing as

Substrate Support Minimum Stucco Industry Standard: Panelized sheathing as a substrate support for exterior stucco wall cladding is required to be discontinuous at BMJS. Suggestions: Substrate Support Planar Tolerance and

Shims Minimum

Stucco Industry Standard: Substrate support framing and sheathing must be within planar tolerance

before the stucco wall cladding system is installed. 1/8 in. in 10 feet for steel stud framing,

¼ in. in 10 feet for wood framing and solid concrete or masonry support

substrates. Use of shims with BMJS is not a recognized

installation method in ASTM C1063 and not allowed. Avoid

shimming BMJS lath accessories to avoid stucco performance discrepancies. Correct substrate support framing and sheathing that exceeds allowable

planarity tolerance before installing lathing and lath accessories. Stucco

Best Practice: Eliminate or minimize localized planarity offsets in the

substrate support to minimize portland cement-based plaster and stucco

thickness variations and stress concentrations that may cause cracking. Suggestions: BMJS Lath Accessories Minimum Stucco Industry Standard: ·

Two different BMJS

lath accessories are produced, each with their own purpose and

characteristics. The Washam design is

suitable for vertically-oriented conditions on walls.

The Pilz

design is suitable for horizontally-oriented conditions on wall to provide a

drainage function. ·

Use BMJS lath

accessories made of materials that will not corrode under normal ambient

environmental conditions of the exterior stucco wall cladding installation, which may

require solid zinc alloy, stainless steel or PVC BMJS lath accessory

materials at corrosive conditions. ·

Avoid larger

dimension solid zinc and PVC BMJS lath accessories to avoid distortions from

thermal movements. ·

Manufacturers

of BMJS lath accessory components are encouraged to publish complete

technical specifications of their BMJS products, installation requirements, dimensions,

movement capacity, fastening, splicing, joinery and sealing requirements and

any usage restrictions or performance limitations. Suggestions:

Omission of BMJS Subassemblies Minimum Stucco Industry Standard: ASTM C926 and C1063 require BMJS at all stucco wall cladding systems as

referenced in the IBC building code, at building structure substrate support

movement conditions without exception. Suggestions: Discontinuous

Lath Minimum Stucco Industry Standard: Discontinuous lath at BMJS is required by

ASTM C1063, to accommodate building structure substrate support movements, and is a Minimum Stucco

Standard of Care. The adjacent lath edges of discontinuous

lath at BMJS must be nailed, screwed or stapled to the substrate support,

framing or blocking, to minimize stucco panel edge curling. Minimum

Stucco Industry Standard: Use the appropriate fasteners to attach the BMJS

to the substrate support. Stucco

Best Practice: Indicate required fastener types, sizes spacing

locations etc. in construction documents. Suggestions: BMJS Subassembly Locations Minimum Stucco Standard of Care: ·

The

design authority is responsible to graphically depict locations for BMJS in

the contract documents as required by Minimum Stucco Industry Standards. Provide complete details of the subassembly

installation requirements, including fasteners, framing and blocking members,

terminations, splices and intersection conditions. Minimum Stucco Industry Standards do not

require or suggest that stucco craftsman be responsible to locate these joint

subassemblies. ·

Typical building structure substrate support

movement locations can be anticipated such as at beam and floor deflection slip tracks,

beam deflections, interstory drift joints, seismic

joints, etc. Stucco

Best Practice: Strategically

locate BMJS at the exterior stucco wall cladding system at the following

locations: ·

Terminate

and butt splice BMJS only at intersections with other stucco movement joints

or exposed lath accessories. ·

Avoid dead

end terminations and butt splices along stucco panel edges away from stucco

panel corners. Suggestions: Horizontally-oriented BMJS Subassembly on

Walls Stucco

Best Practice: ·

At horizontally-oriented BMJS

locations on exterior weather exposed walls, use the Pilz

design BMJS lath accessory with a sloped drainage surface, and subassembly

and integrate the extended flashing flange with the WRB. ·

Locate butt splices at intersections with other lath

accessories and avoid splices along stucco panel edges Suggestions:

Vertically-oriented BMJS Subassembly on Walls Stucco

Best Practice: ·

At vertically-oriented BMJS

locations on exterior weather exposed walls, use the Washam design BMJS lath

accessory and subassembly. ·

Locate butt splices at intersections with other lath

accessories and avoid splices along stucco panel edges Suggestions: BMJS Intersections with SMJS subassemblies Minimum

Stucco Industry Standard: At intersections of BMJS and SMJS, install

the BMJS continuous through the intersection. Suggestions: Sealant at Splices, Terminations,

Intersections Minimum Stucco Industry

Standard: Follow

Sealant and Stucco webpage suggestions. Stucco

Best Practice: Follow

Sealant and Stucco webpage suggestions. Suggestions: Low-Slope Weather-Exposed Surfaces Minimum

Stucco Industry Standard: Recognize that stucco is a wall cladding system, not a roofing

material, and stucco cladding with BMJS on low-slope, weather-exposed

conditions is not an optimum solution. Stucco

Best Practice: Avoid stucco cladding at low-slope,

weather-exposed surfaces. At low-slope

weather-exposed conditions, provide durable materials appropriate for roofing

conditions such as sheet metal copings and concealed waterproofing. Suggestions: Ornamental Features Stucco

Best Practice: Terminate ornamental materials at either side of the BMJS so

that building structure substrate movement is free to occur to minimize

damage to the ornamental features and stucco wall cladding system. If visual continuity is desired, use

resilient sealant of appropriate color, over backer rod to span the gap over

the BMJS. Stucco

Best Practice: Recognize that the BMJS lath accessory and

subassembly are not perfect solutions to portland cement-based plaster and

stucco cracking, but they are the best solutions available. Use BMJS correctly, recognizing and

accommodating their limitations for maximum effectiveness. Seal the separation gap, splices,

intersection and transitions watertight. Suggestions: Detail Drawings – BMJS Subassembly The following detail drawings are

diagrammatic depictions of BMJS configurations, in horizontal and vertical

orientations on an exterior building wall, but are not sufficient enough in

detail to be construction documents.

Their purpose is merely to diagrammatically illustrate the

relationships of various essential components of a functional BMJS.

Weather-exposed wall

condition

Weather-exposed wall

condition |

||||||||||||||||||||||||||||||||||||||||||||

|

(1)

ASTM

International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA

19428-2959. United States (2)

NAAMM Standard EMLA 920-09, Guide

Specifications for Metal Lathing and Furring, Fifth Edition, National

Association of Architectural Metal Manufacturers, 800 Roosevelt Road, Glen

Ellyn, IL 60137 |

||||||||||||||||||||||||||||||||||||||||||||

|

Consultation with licensed and experienced stucco professionals

is recommended for stucco-related endeavors.

No liability is accepted for any reason or circumstance, specifically

including personal or professional negligence, consequential damages or third

party claims, based on any legal theory, from the use, misuse or reliance

upon information presented or in any way connected with StuccoMetrics.com. |

Home Page Contact Me Disclaimer