|

StuccoMetrics® |

Jeff Bowlsby CCS, CCCA

Exterior Wall and Stucco Consultant

Licensed

California Architect

Stucco Perimeter Movement Joint

Subassembly (PMJS)

(“expansion joint” at internal corner)

|

Webpage Quicklinks Detail Drawings - PMJS Subassembly |

||||||||||||||||||||||||||||||||||||||||

|

To

determine which stucco movement joint is appropriate for a given condition,

one must understand the anticipated movement at the condition. Shrinkage and thermal movements occur in

the lath and stucco membrane. BMJS,

PMJS and SMJS each accommodate shrinkage and thermal movements because the

lath and stucco composite membrane is discontinuous through and terminate at

each side of these subassemblies. A

SMJS does not accommodate substrate support movement because the substrate

support is continuous at SMJS. BMJS

and PMJS accommodate substrate support movement because the substrate support

is discontinuous at these subassemblies.

Stucco Movement Joint

Selection Matrix PMJS are not mentioned in the building

code or Minimum Stucco Industry Standards by name, but generically they are

described as “perimeter relief” or simply as “expansion joints” at internal

corner locations. In search of clarity

I derived the term Perimeter Movement Joint Subassembly (PMJS) and use it on

this website for easier recognition and intuitive understanding, and because

it clearly describes the function of this stucco movement joint subassembly,

and describes that it is a subassembly and not just a lath accessory. An understanding of the primary function of

the PMJS, the purposes it serves and how it is to function as presented here,

will resolve any lingering debate about its function and how and where to

install it. The PMJS, its intended purpose, function, and installation configuration

can be misunderstood amongst building owners, architects and craftsman. If cracking did not occur, stucco would be

much more popular, respected and prolifically used as an exterior wall

cladding. These are the intended

outcomes of these webpages regarding stucco movement joints. Portland cement plaster shrinkage

movement during curing and thermal movements while in service and building

substrate movements are significant factors that when combined, can

contribute to stucco cracks. While

shrinkage movement, thermal movement and building movement are important, it

is recognized that other factors can contribute to cracking so addressing

these movements alone, are not the only factors contributing to stucco

cracking. This webpage focuses

primarily on the issue of stucco shrinkage movement, thermal movement and

building substrate movement and methods to minimize their contributory

effects to stucco cracking. The PMJS is a limited application, special

condition stucco perimeter movement joint subassembly, not merely just the

perimeter movement joint lath accessory component itself. While not as common as other stucco movement

joints, the PMJS was the original form of the stucco “expansion joint”

subassembly genre, and its development has taught us many things about stucco

behavior towards minimizing stucco cracks.

The PMJS creates an isolated stucco perimeter edge to accommodate

stucco movement. A PMJS is required by

Minimum Stucco Industry Standards to be provided for lath and stucco at

internal corner planar transitions under the following conditions: ·

When an internal corner is oriented vertically, horizontally or in any

direction and, ·

Where each adjacent planar substrate support is of different materials,

or ·

Where each adjacent planar substrate support is of different

loadbearing characteristics Stucco cracks related to internal

corners at the transitions of substrate support materials or transitions in

substrate material loadbearing conditions can be caused by stucco substrate

support movement, stucco shrinkage movement and stucco thermal movement. More specifically, these conditions occur

where continuous stucco cladding is installed at internal corners such as

where a framed, furred or suspended ceiling adjoins a concrete wall or

concrete column (transition of substrate support materials and transition of

substrate support loadbearing/non-loadbearing conditions) or at a vertical

wall internal corner where a framed wall adjoins a concrete or masonry wall

(transition of substrate support materials).

Minimum Stucco Industry Standards require that at substrate support

material and loadbearing condition transitions that the lath is terminated

and fastened to the substrate support and stucco is terminated at either side

of the internal corner and both are discontinuous through the PMJS

subassembly gap. Under these

conditions, a PMJS accommodates the differential movements occurring at each

adjacent plane at an internal corner and relieves stresses to minimize stucco

cracks. This webpage explores the conditions that make the PMJS beneficial to

the success of an exterior stucco wall cladding system on a building as a

substrate support. Visit the StuccoMetrics Reference Archives

webpage for cited references and further information. |

||||||||||||||||||||||||||||||||||||||||

|

Patent research: No patented PMJS lath accessory components are known to be patented. In the 1940’s the common

stucco lathing practice was to install lath continuously over all substrates,

which articulated continuously over and around all planar transitions. The belief was that continuous lath

provided a continuously rigid, restrained lath structure for continuous stucco,

conceptually similar in function to a solid base that was thought to minimize

any potential movements and reinforce the stucco to minimize cracks. A typical example of this practice was

stucco continuously and directly-applied onto a vertical load-bearing

concrete wall which then transitioned through a wall-to-ceiling juncture,

onto a horizontal suspended grillage/lath ceiling, where the ceiling lath was

intentionally extended onto and secured to the adjacent wall surface.

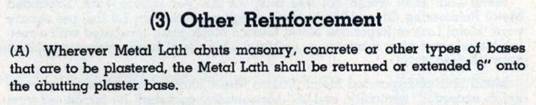

From

Metal Lath Specifications Metal

Lath Manufacturers Association, 1946 As described for us in

the 1947 ACI Journal article Crack

Control in Portland Cement Plaster Panels(2), a major stucco installation was constructed at the Grand

Coulee Dam construction project that featured direct-applied stucco installed

onto concrete walls which then continued uninterrupted onto adjacent

suspended grillage/lath ceilings, where ceiling lath was extended onto and

secured to the adjacent walls. The

installation experienced significant and unacceptable cracking at the stucco

on suspended metal lath ceilings.

Extensive investigation and testing was performed by the Bureau of

Reclamation to evaluate a long list of possible causes, to determine the

primary cause of the ceiling cracking and to develop a solution. The primary conclusion was that the ceiling

cracking occurred because the lath and stucco at the ceiling perimeter was

attached to and restrained by the attachment at the perimeter concrete walls,

and therefore the ceiling stucco subassembly was not able to accommodate the

stucco shrinkage movement. Not

mentioned in the article, other contributory causes of ceiling cracking for

this condition likely included stucco thermal movement, differences in stucco

behavior at the transition between different support substrate materials

(grillage/lath to concrete), and differences in support substrate loadbearing

conditions at the transition between loadbearing to non-loadbearing

conditions (suspended ceiling to concrete wall) and potentially other

contributory causes. The primary solution

derived a method of application that included eliminating “restraint at all edges

of the plaster slab, allowing shrinkage to take place without stress

development and the attendant cracking.”

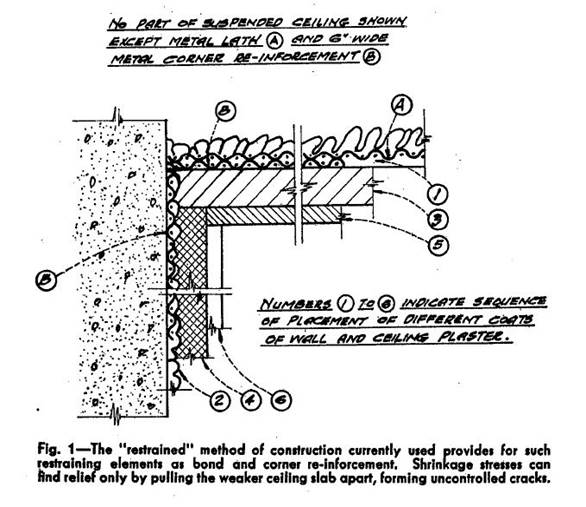

Discontinuing the ceiling lath at its perimeter and not securing it to

the wall, detached the mechanical attachment of the ceiling lath from the

perimeter concrete walls which eliminated the perimeter lath restraint

condition, prevented the stucco from bridging across the transition at the

ceiling to wall internal corner location, and created a visible joint line in

the stucco at the transition, but the joint line was not objectionable. This isolation solution also addressed the

potential causes of cracking from thermal movement, from the differences in

the stucco behavior at the transition between different substrate support

materials (grillage/lath to solid concrete), and from differences in

substrate support loadbearing conditions at the transition from loadbearing

to non-loadbearing conditions. After reconstructing the

suspended ceiling as an isolated subassembly from the perimeter concrete

walls, no ceiling cracks occurred, and the ceiling perimeter shrinkage gaps

measured 3/4 in. of total shrinkage over its 52 ft. length.

Grand Coulee Dam ceilings - Restrained lath and stucco

perimeter Condition created by continuous lath at ceiling-to-wall

internal corner that caused ceiling cracks From Crack Control in Portland Cement Plaster Panels, by

Bert Hall, American Concrete Institute Journal, Vol. 19, No. 2, October 1947 Figure reproduced with permission from

the American Concrete Institute

Perimeter Movement Joint Subassembly (PMJS) (lath and stucco

not restrained at the perimeters) at a ceiling-to-wall internal corner, which

eliminated ceiling cracks. Note

the transition between different substrate support materials (suspended

grillage/lath to concrete) and transition between different substrate support

loadbearing conditions (non-loadbearing to loadbearing). From Crack Control in Portland Cement Plaster Panels, by

Bert Hall, American Concrete Institute Journal, Vol. 19, No. 2, October 1947 Figure reproduced with permission from

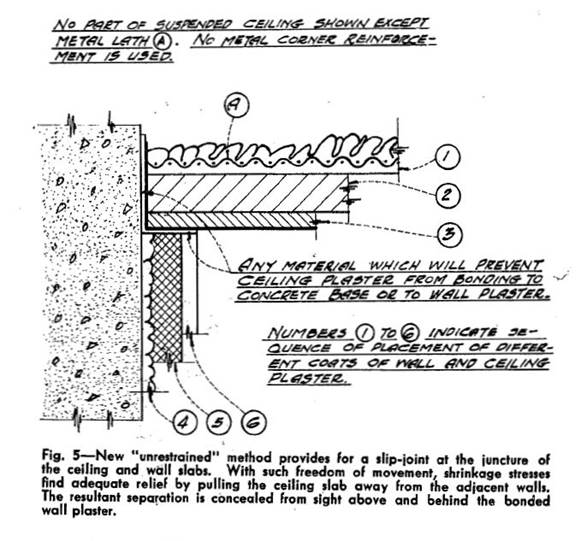

the American Concrete Institute The Grand Coulee Dam

ceiling shrinkage event was not an isolated occurrence. A similar circumstance was reported in a

1985 article in AWCI’s Construction Dimensions magazine, Controlling Shrinkage in Portland

Cement Plaster(3), at a new Chicago parking garage ceiling at the first

level of a new office tower. In a

ceiling installation similar to Grand Coulee but on a much larger scale, a

45,000 SF suspended grillage/lath structure supporting stucco was installed.

This time the ceiling was not attached (restrained) to the inside of

perimeter concrete walls that formed the building perimeter and the garage

ceiling was also penetrated by support columns and fire sprinkler

penetrations. At this installation,

the perimeter of the stucco ceiling subassembly was constructed of casing

beads aligned and butted to the perimeter concrete walls, but the lath was

not attached to the walls, just to the suspended ceiling lath and its support

grillage. Wide gaps developed at the

building stucco ceiling perimeter juncture with the walls, and at the columns

and fire sprinkler penetrations through the ceiling, attributed to stucco

shrinkage movement at the ceiling. It

was Grand Coulee déjà vu.

Unrestrained stucco ceiling shrinkage Chicago parking garage,

1985 From Controlling Shrinkage in Portland Cement Plaster, Construction Dimensions Magazine,

September 1985 Minimum

Stucco Industry Standards for stucco wall cladding systems are indicated below.

Readers are encouraged to purchase the referenced

ASTM Standards directly from ASTM and review them. The referenced ASTM Standards and texts are

indicated for reader’s convenience, for purposes of topical discussion. Requirements

of the Standards are paraphrased, written in the imperative mood and

streamlined writing format as is recommended by the Construction Specifications

Institute (CSI) and common to construction specifications, using the

terminology developed and described on StuccoMetrics.com. ASTM

C1063 Standard Specification

Installation for Lathing and Furring to Receive Interior and Exterior

Portland Cement-Based Plaster(1: ·

(7.10.1.6) Provide PMJS with 3/8-in. (9.5-mm)

separation gap where furred or suspended ceilings and soffits adjoin

penetrating elements such as columns, walls or beams. Discontinue lath through PMJS, cornerite not allowed. ·

(7.10.1.7) Provide BMJS or PMJS with 3/8-in. (9.5-mm)

minimum separation gap where load bearing walls or partitions adjoin

structural walls, columns or floor or roof slabs. Discontinue lath through BMJS or PMJS, cornerite not allowed. ·

(7.11.4.3) Provide BMJS or PMJS aligned with expansion

joint in substrate support. ASTM

C926 Standard Specification for

Application of Portland Cement-Based Plaster(1): ·

(A2.1.3) Seal separation gaps between weather exposed

plastered panel edges and dissimilar materials to prevent water penetration. ·

(A2.3.1) Reference the Installation Section of

Specification C1063 for PMJS and SMJS installation requirements used with

metal plaster base. PMJS and SMJS are

not required at solid plaster bases, except as stated in Specification C1063

7.11.4.3. ·

(A2.3.1.2) Evaluate the

characteristics of the substrate and indicate the requirements for BMJS, PMJS

and SMJS on construction documents, including type, location, depth, installation

requirements. Install BMJS, PMJS and

SMJS before plastering. ·

(A2.3.1.3) A groove in

plaster is not a BMJS, PMJS or SMJS. ·

(A2.3.3) Provide a BMJS, PMJS or SMJS at transitions

between dissimilar substrate support materials that receive continuous

plaster. |

||||||||||||||||||||||||||||||||||||||||

|

We learned significant

lessons about stucco behavior and performance from the Grand Coulee Dam and

Chicago parking garage ceilings related to the specialized instance of stucco

cracking related to continuous stucco at internal corners. One lesson was that “the shrinkage

coefficient of cement mortar or plaster is the basic element for

consideration in crack eliminations.”

Other lessons learned involve the various restraint conditions

regarding lath and stucco at stucco panel internal corners including

restrained substrate movement, restrained lath and stucco shrinkage movement,

restrained stucco thermal movement, and that restrained movements may

manifest as stucco cracking: ·

Lath and stucco

applied continuously over framed support substrates (without dividing the

lath and stucco into discrete isolated panels), is

prone to crack. ·

Lath and stucco where continuous

and attached at stucco panel perimeters, is prone to crack ·

Lath and stucco

applied continuously over transitions between different support substrate

materials, such as from wood framing to concrete or from suspended steel

grillage to concrete, is prone to crack. ·

Lath and stucco

applied continuously over transitions between different support substrate

loadbearing conditions such as from non-loadbearing to loadbearing, is

prone to crack. We also learned about how

a PMJS addresses perimeter restrained lath and stucco conditions, by

isolating adjacent stucco planes at internal corners to minimize stucco

cracking. ·

A PMJS isolates

adjacent stucco panels, isolates and accommodates stucco substrate movement,

stucco shrinkage movement and stucco thermal movement and allows these

movements to occur unrestrained because of discontinuous lath and stucco at

stucco panel perimeters and internal corners, to minimize stucco cracks. ·

Stucco cracks occur

from restrained transitions between different substrate support

materials such as between suspended grillage/lath to concrete, or between

framing to concrete. A PMJS isolates

the different adjacent stucco behaviors at the transition location between

different substrate support materials, to minimize stucco cracks. ·

Stucco cracks occur

from restrained transitions between different substrate support

loadbearing conditions such as between non-loadbearing elements to

loadbearing elements. A PMJS isolates

the different adjacent stucco behaviors at the transition location between

the different substrate support loadbearing conditions, to minimize stucco

cracks. Minimum

Stucco Industry Standards ASTM C926 and C1063 are

referenced standards in the building code which state minimum installation requirements for PMJS lath accessories and

subassemblies. Where the substrate

support material and substrate support loadbearing conditions are the same,

and where the substrate support condition is continuous on either side of an

internal corner, a PMJS is not required, however when installed may be beneficial

in accommodating shrinkage to minimizing stucco cracking. |

||||||||||||||||||||||||||||||||||||||||

|

Building structures and materials are exposed to

and must accommodate various structural and physical forces and their related

deflections or movements to function as expected. Gravity loads cause

vertical building movements such as beam and floor slab edge

deflections. Wind and seismic loads

cause lateral building movements such as inter-story drift. Stucco, as one of the few exterior wall

cladding materials applied as a wet material, experiences shrinkage movement

as the stucco cures. Daily and

seasonal ambient thermal variations cause expansion and contraction movements

within all building construction materials.

Each of these movements must be accommodated in some way or the

building and its cladding material will not function as anticipated. Building structural movements, expressed either

vertically or laterally, as a substrate support for stucco, are accommodated

with BMJS or PMJS. Shrinkage and

thermal movements are accommodated with a SMJS. BMJS and PMJS also accommodate shrinkage

and thermal movements because the lath is not continuous through these

joints, but shrinkage movements and thermal movements are not the primary

function of BMJS and PMJS. The PMJS is a

specific configuration of stucco and its components at internal corners

including the associated substrates, lath, lath accessories, lath fasteners,

lath accessory attachments, and stucco mortar that allow the perimeter edges

of adjacent stucco panels to accommodate substrate, shrinkage and thermal

movements including at transitions of substrate support material or substrate

support loadbearing conditions. PMJS

for internal corners are “expansion joint” subassemblies to accommodate

movements from differential substrate support conditions that need to be

accommodated to minimize stucco cracking.

The need for and development of PMJS at internal corners of planar

transitions was recognized before and preceded the development of both SMJS

and BMJS for continuous wall surfaces and yet share similarities with both in

addressing stucco and substrate movement conditions that cause cracks.

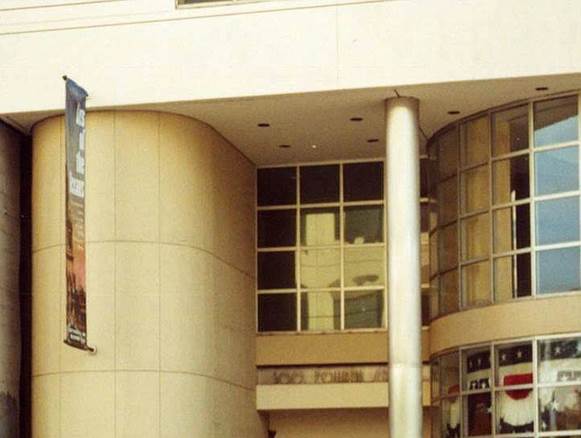

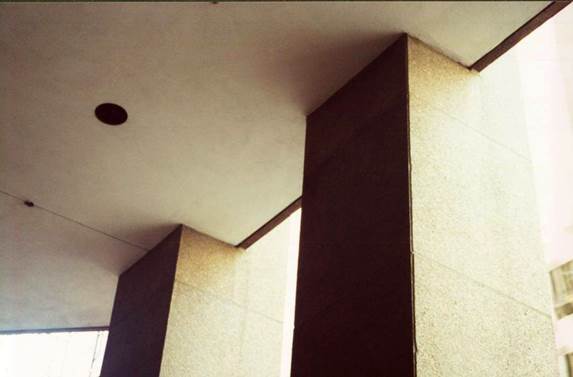

Horizontal

PMJS subassembly at building entry soffit at interface with

curved wall and round column

Horizontal

PMJS subassembly at arcade soffit at interface with square columns Minimum

Stucco Industry Standards provide limited but important and useful basic

information on PMJS. Minimum Stucco

Industry Standards for PMJS are defined in the building code which includes

reference standards ASTM C926 and C1063.

In the codes, requirements for the PMJS are described generically as

“expansion joints” but the term “PMJS” is not named. The

earliest and simplest form of a PMJS is jobsite fabricated from two adjacent

casing bead lath accessories, separated by a gap to accommodate

movements. The gap width dimension

between the casing beads, should be 3/8 in minimum where sealant is required,

and shall be determined by the amount of movement anticipated and may be

filled with a resilient sealant for aesthetic or water management

purposes. To function correctly, a PMJS requires discontinuous substrate support

materials, discontinuous lath and discontinuous stucco to create an isolated,

unrestrained condition, where the lath edges are fastened to framing or

blocking on either side of the PMJS to allow for maximum movement potential

at the PMJS. The conditions requiring

the PMJS itself are described, although

the PMJS is not specifically named, in industry reference documents since the

1971 ANSI A42.3 and is described in Minimum Stucco Industry Standard ASTM

C1063 today, so the need for the PMJS and its requirements are not new. Where

the PMJS is located at a weather-exposed surface (WES), a flexible barrier

membrane, continuous WRB and sealant in the gap are required. At non-weather-exposed surfaces the sealant may be optional, serving an

aesthetic function only. PMJS lath

accessories also function as stucco thickness control screeds and temporary

work stoppage locations which prevent cracks caused by stucco cold joints. Adjacent casing beads are the predominant PMJS lath

accessory(s). One specialized PMJS

lath accessory is manufactured but detailed PMJS lath accessory engineering

technical and performance information is not available for this lath

accessory. No industry product

standard exists that specifies the engineering, performance and technical

aspects of the PMJS lath accessory adding to the challenges for designers and

installers to accurately be informed on how to use the lath accessory and

integrate it into stucco wall cladding system. Lath accessory manufacturers are encouraged

to either develop a generic industry product standard for PMJS and fabricate

their lath accessories to conform to the standard or for their proprietary

products at least, provide complete technical and performance information

indicating physical dimensions, materials, fastening and attachment

requirements, splicing methods, termination and intersection methods,

movement capabilities and corrosion resistance properties of the lath

accessory and installation, for design and installation reference. The

design authority must clearly describe the requirement for back-up framing or

blocking and required fasteners in the construction documents, at PMJS

locations, so that lath edges at discontinuous lath can be fastened to

framing. Isolating stucco wall cladding panels

using PMJS located in certain locations such as where columns or loadbearing

elements penetrate the stucco cladding or non-loadbearing elements,

configured in a certain way to accommodate this differential movement, sealed

at critical junctures to effectively manage the effects of water, create a

Perimeter Movement Joint Assembly that minimizes cracking. The Assembly is the sum of its parts,

arranged and functioning together to serve the purpose of minimizing

cracking. No singular PMJS lath

accessory component or PMJS subassembly in isolation can accomplish the

effect of the Perimeter Movement Joint Assembly as a whole on the stucco wall

cladding system. Follow

product manufacturer’s additional recommendations when using their products

(Manufacturer’s instructions for use of their products). |

||||||||||||||||||||||||||||||||||||||||

|

PMJS

are not well understood and are an occasionally overlooked stucco “expansion

joint” subassembly. The real world testing

performed and lessons learned from the Grand Coulee Dam and Chicago parking garage

projects demonstrated that continuous lath and stucco, at the specialized

condition of internal corner locations where bridging over transitions in

substrate support materials and transitions in substrate support loadbearing

conditions, creates restrained lath and stucco conditions that do not

accommodate stucco shrinkage and thermal movements, which may result in

stucco cracks. The Grand Coulee Dam

ceilings forever made continuous lath and stucco, at internal corner

conditions at transitions in substrate materials and transitions in

loadbearing conditions, an obsolete practice.

At the Chicago parking garage ceiling, where the perimeter lath and

stucco at the perimeter wall juncture was not attached (not restrained) it

was an illustration of the severity of effects of stucco shrinkage and

thermal movements that are natural to the material and can cause cracks. The

wide gaps that developed at the unrestrained perimeters and penetrations of

the stucco ceiling, while unanticipated, displayed the nature of stucco on

lath to shrink. |

||||||||||||||||||||||||||||||||||||||||

|

Minimum

Standards of Care: ·

Provide PMJS at locations and conditions

where substrate movements occur at internal corners – column penetrations at

soffits, substrate support material transitions, etc. ·

PMJS lath accessories can be fabricated by installing

casing beads adjacent to each other with a 3/8 in separation gap, or a

specialty 2-piece prefabricated lath accessory. Either subassembly must be constructed with

discontinuous lath and stucco at the PMJS location to isolate adjacent stucco

panels, and accommodate movement to minimize stucco cracking. ·

Where the PMJS occurs at

weather-exposed surfaces, provide

a flexible barrier membrane behind the PMJS and sealant in the

separation gap and at exposed terminations and splices to prevent water

entry. ·

The design authority is required

to determine PMJS locations, select lath accessories including determining

ground depth, determine installation requirements and depict them on the

construction documents. Provide

complete details of the subassembly installation requirements, including

fasteners, framing and blocking members, terminations, splices and

intersection conditions. Minimum

Stucco Industry Standards do not require that the stucco craftsman be

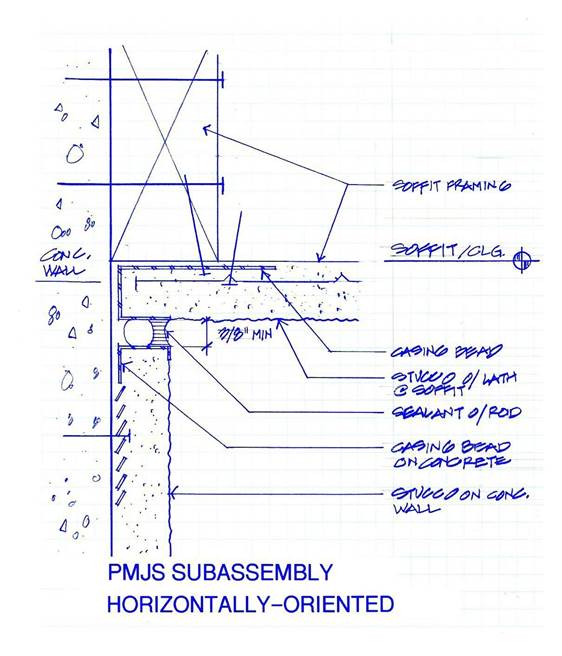

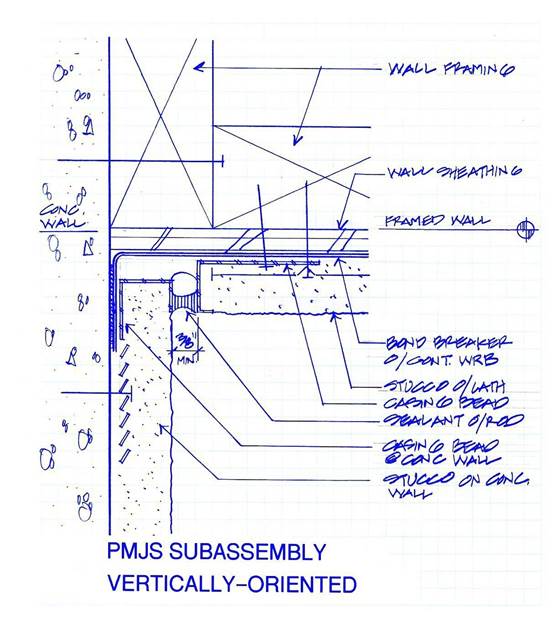

responsible to design or locate these movement joint subassemblies. The following two example details are for

conceptual information only, require additional supplemental details for

conditions such as PMJS terminations, articulations and splices, and to meet

specific application requirements. Stucco Best Practice:

PMJS lath accessory manufacturers should provide engineering technical

documentation for dedicated PMJS lath accessories and for arrangements of

casing beads used as PMJS lath accessories, describing their products: ·

Physical dimensions ·

Material properties ·

Detailed and comprehensive installation requirements if not explicitly

stated in ASTM C1063 such as attachment, joinery and splicing methods,

fastener requirements, conditions and requirements for sealant at

terminations, joints and splices, etc. ·

Performance characteristics:

Movement capabilities and limitations when installed into stucco as a

PMJS Suggestions: Detail Drawings – PMJS Subassembly The following detail drawings are

diagrammatic depictions of PMJS configurations, in horizontal and vertical

orientations on an exterior building wall, but are not sufficient enough in

detail to be construction documents.

Their purpose is merely to diagrammatically illustrate the

relationships of various essential components of a functional PMJS.

Weather-protected soffit condition

Weather-exposed wall condition |

||||||||||||||||||||||||||||||||||||||||

|

References (1)

ASTM

International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA

19428-2959. United States (2)

Crack

Control in Portland Cement Plaster Panels, Bert Hall, Journal

of the American Concrete Institute,

Vol. 19, No. 2, October 1947 (3)

Controlling

Shrinkage in Portland Cement Plaster, John Boland,

Construction Dimensions Magazine, September 1985 |

||||||||||||||||||||||||||||||||||||||||

|

Consultation with licensed and experienced stucco professionals

is recommended for stucco-related endeavors.

No liability is accepted for any reason or circumstance, specifically

including personal or professional negligence, consequential damages or third

party claims, based on any legal theory, from the use, misuse or reliance

upon information presented or in any way connected with StuccoMetrics.com. |

Home Page Contact Me Disclaimer