|

StuccoMetrics® |

Jeff Bowlsby CCS, CCCA

Exterior Wall and Stucco Consultant

Licensed

California Architect

Stucco and Sealant

|

Webpage Quicklinks Holes At Removed Lath Fasteners in WRB Gaps At Weather-Exposed Trim Splices,

Intersections, Terminations Sealant Used for Decorative Purposes |

|

An exterior stucco wall cladding system does not

need sealant or caulk for its own needs, but sealant or caulk is significant if

not critical to the effectiveness of the exterior building enclosure system

as a whole, for which the exterior stucco wall cladding system plays an

integral part. Water intrusion through building enclosure systems

is a major cause of property damage, a catalyst for legal action and

liability exposures for all parties and conditions related to building

enclosures in general and exterior stucco wall cladding systems in

specific. Let us not forget that

issues concerning sealant decimated the EIFS industry, but the EIFS cladding

material itself was not especially problematic. We cannot let history repeat itself and be

myopic regarding stucco. Stucco wall

cladding systems may be headed in the same direction as EIFS if the omission

of sealant causes even the perception that water-related issues may be

related to the stucco exterior wall cladding system. The possibility of water intrusion

associated with stucco wall cladding systems can be minimized with the

careful, considered and strategic use of sealant or caulking. The use of sealant or caulk at stucco clad

weather-exposed surfaces at lath accessory joint splices, intersections, terminations, and at

stucco panel edges to prevent water penetration, although granted could be

stated more clearly, is reasonably inferable as a building code requirement

and Minimum Stucco Industry Standard, and has strong support by significant

reference resources in the stucco industry. Visit the StuccoMetrics Reference Archives

webpage for cited references and further information. |

|

Minimum

Stucco Industry Standards for stucco wall cladding systems are indicated below.

Readers are encouraged to purchase the referenced

ASTM Standards directly from ASTM and review them. The referenced ASTM Standards and texts are

indicated for reader’s convenience, for purposes of topical discussion. Requirements

of the Standards are paraphrased, written in the imperative mood and

streamlined writing format as is recommended by the Construction

Specifications Institute (CSI) and common to construction specifications,

using the terminology developed and described on StuccoMetrics.com. ASTM C1063 Standard Specification

Installation for Lathing and Furring to Receive Interior and Exterior

Portland Cement-Based Plaster(1: ·

(7.11.3) Casing Beads: Terminate plaster at panel edges and at

dissimilar materials with casing beads.

Provide separation gap between plaster panel edges and dissimilar

materials to isolate non-loadbearing members from loadbearing members /

penetrating elements and prevent the transfer of structural loads. ASTM C926 Standard

Specification for Application of Portland Cement-Based Plaster(1). This text has not fundamentally changed since the first

edition of C926 in 1986 and before that in its predecessor ANSI A42.2-1971 Portland Cement and Portland Cement-Lime

Plastering Exterior (Stucco) and Interior(2): ·

(A2.1.3) Seal separation gaps between weather

exposed plastered panel edges and dissimilar materials to prevent water

penetration. In addition, various other stucco

industry reference resources establish a strong precedent for sealant use

with stucco wall cladding systems, assemblies, subassemblies and components

including embedment of lath accessory splices, intersections and

terminations, to keep bulk water out of the exterior stucco wall cladding

system. The following reference

resources should be considered advisory because they are either for

historical reference and have been superseded by more current reference

resources from the same organizations, or are not codified in the Minimum

Stucco Industry Standards: ·

1971 ANSI A42.3 – “A2.1.4 On exterior work V-grooves shall be caulked

or sealed to prevent entry of water.”(2) ·

c.1980 Technical

Manual, Keene Corporation, Penn Metal Products(3):

“On vertical surfaces it may mean the installation of caulking or weatherstrip beneath the control joint to seal the

opening…” ·

c.1980 Control Joints in Exterior

Portland Cement Plaster, Western Conference of Lathing and Plastering

Institutes, Inc.(WCLPI)(4): “All intersections and terminations of control

joints should be embedded and weather-sealed with caulking.” ·

1981 Minimum Property Standards,

US Department of Housing and Urban Development (HUD)(5): Required compliance with 1971 ANSI A42.3,

as discussed above. ·

1983 Keene

Corporation product catalog(6): “Intersections

of “joints” may be butted-and-calked...” ·

1991 920-91 Guide Specifications

for Metal Lathing and Furring, Metal Lath/Steel Framing Association

(ML/SFA Division of NAAMM)(7): “All intersections and terminations of “control joints”

should be embedded and weather sealed with caulking.” Drawing entitled “Control Joint Intersections” depicts two control joint

intersection conditions, both indicating sealant at the intersections.

Drawing entitled “Screwable Steel Framing” depicts multiple

locations of sealant caulking at stucco panel perimeters to adjacent

construction. ·

1993 Guide to Portland Cement

Plastering, ACI 524R(8),

American Concrete Institute: “Joints, intersections and terminations of control

joints, should be embedded and weather-sealed.” “Terminations or splices in “stress-relief

joints” should be embedded within a weather-resistant elastic sealant to

prevent moisture penetration.” ·

1996 Portland Cement Plaster

(Stucco) Manual, EB049 Portland Cement Association(9): “All

joints, intersections, and terminations of control joints should be embedded

and weather-sealed.” ·

1997 Stucco Resource Guide,

Northwest Wall Ceiling Bureau(10):

“4.6 Control members shall be

fit together neatly at intersections and splices and shall fit neatly at

terminations. In wet areas, splices

and intersections should be set in sealant or buttons of sealant should be

applied after control joint installation.” ·

1999 Stucco Resource Guide,

Northwest Wall Ceiling Bureau(11): “21. It is recommended that trim accessory

joints be weather-sealed by embedment in caulking at intersections, when

placed end-to-end, abutting one another and at terminations.” ·

2001 Systems Manual, Texas

Lathing and Plastering Contractors Association & the Texas Bureau for

Lathing and Plastering (12):

“21. It is recommended that

trim accessory joints be weather-sealed by embedment in caulking at

intersections, when placed end-to-end, abutting one another and at

terminations.” ·

2003 Portland Cement Plaster

(Stucco) Manual, EB049 Portland Cement Association(13): “All

joints, intersections, and terminations of control joints should be embedded

and weather-sealed.” ·

2004 Guide to Portland Cement

Plastering, ACI 524R, American Concrete Institute(14): “Terminations

or splices in the control joint should be embedded within a weather-resistant

sealant to prevent moisture penetration.” ·

2007 Stucco in Residential

Construction, Minnesota Lath and Plaster Bureau(15)

(2000, 2004 editions identical):

“The subsequent joint between the window and stucco at the sill and

jambs are then filled with a closed cell bond breaker and low modulus

elastomeric sealant [illustrated].”

Various illustrations of stucco wall cladding system openings and

penetrations including deck attachment, deck handrail attachment, piping and

vent sleeves, hose bibs and dryer vents, light fixtures and outlets depicted

and described as sealed. ·

2008 Guide to Portland Cement

Plastering, ACI 524R, American Concrete Institute(16): è

“Terminations or splices in “stress-relief joints”

should be embedded within a weather-resistant elastic sealant to prevent

moisture penetration.” è

“Specify and detail the installation of flashing,

weep screeds, and sealant at doors and around windows, vents, and all other

wall penetrations to ensure that water will be diverted or channeled to the

outside of the wall assembly in accordance with ASTM C1063 and E2112.” è

“Specify and detail the use of sealant at

“stress-relief joint” terminations and splices” è

“Specify and detail the use of sealant at wall

penetrations to prevent leakage at these points.” ·

2009 AMICO product catalog(17): “Flashing

should be applied in the form of asphalt saturated construction paper or

flashing strips behind all expansion joints and all joints should be imbedded

[sic] in caulk.” ·

2009 Guide Specifications for Metal Lathing and

Furring, EMLA 920-09(18), regarding sealant use at metal lath

accessories: è

“Joinery of abutting ends of trim accessories should

be spliced or lapped and sealed with appropriate sealant.” è

“Joinery of “control joint” intersections should

be spliced or lapped and sealed with appropriate sealant.” è

“Joinery of flashing sections should be

appropriately lapped, sealed and mended together by applications of sealants,

adhesive backed membrane or other appropriate means of continuity.” è

“Stucco terminations at penetrations should be

sealed with sealant to the metal side of the flashing or stucco trims. Not to the face of the brown coat or finish

coat.” è

““Control joints” should be sealed at

inside/outside corners and termination points.” è

“All intersections and terminations of “control

joints” must be embedded and weather-sealed in a bed of caulking material.” ·

2009 Lath Inspection Resource

Manual, Second Edition, Minnesota Lath & Plaster Bureau(19)

(2005 Edition identical):

General Notes, “Joinery of abutting ends of trim accessories should be

spliced or lapped and sealed with appropriate sealant.” “Joinery of control joint intersections

should be spliced or lapped and sealed with appropriate sealant.” References on numerous detail photos of

stucco panel edges, “control joints”, “expansion joints”, splices, intersections

and terminations, pipe and vent flashings, be sealed because they are

“vulnerable to moisture intrusion”. ·

2011 Plaster Assemblies Manual

Online, Technical Services Information Bureau (TSIB)(20):

“It is recommended that in areas subjected to wind-driven rain,

control and expansion joint terminations/intersections be set in sealant or

buttons of sealant for wet locations.” ·

2014 Fasteners and Self-Sealability of

Weather-Resistive Barriers, RCI-TA-005-2014, Roof Consultants Institute

Technical Advisory(21): “The potential for water intrusion

through fastener penetrations—particularly with claddings like siding,

stucco, and adhered masonry veneer, where thousands of fasteners can be used

to attach the siding or metal lath through the air barrier—can be minimized

by following common practices as follows: è Confirm

fasteners engage with studs/framing or a sound substrate. è Avoid

the use of supplemental fasteners, sometimes used incorrectly to attach accessories

between studs such as control joints and other accessories in stucco

(required to be wire tied between studs). è Avoid

errant fasteners that do not go through studs or spin and create a larger

opening, as well as loose connections (particularly in gypsum-based

sheathing). è Remove

“loose” fasteners and seal the holes. è Avoid

the use of powder or power-actuated fasteners.” ·

2014 Plaster and Drywall Assemblies

Manual, Walls and

Ceilings Magazine(22): “It is recommended that in areas subjected

to frequent wind-driven rain, control joint and expansion joint

terminations/intersections be set in sealant or buttons of sealant to prevent

moisture intrusion.” Additionally, review the following ASTM standards for

general information about sealant specification, sealant joint design and

installation and sealability of fasteners: ·

ASTM C1193 Standard

Guide for Use of Joint Sealants(1) ·

ASTM C920 Standard

Specification for Elastomeric Joint Sealants(1) ·

ASTM

D1970 Standard Specification for Self-Adhering Polymer Modified Bituminous

Sheet Materials Used as Steep Roofing Underlayment for Ice Dam Protection(1) ·

ASTM

E2112 Standard

Practice for Installation of Exterior Windows, Doors and Skylights(1) ·

ASTM

E2128 Standard

Guide for Evaluating Water Leakage of Building Walls(1) ·

ASTM

E2266 Standard Guide for Design and Construction of Low-Rise Frame Wall

Systems to Resist Water Intrusion(1) While other stucco industry reference resources are silent on the issue of

sealant or caulk at lath accessory splices,

intersections and terminations, none specifically recommend against

sealant, or require that sealant or caulk not be

used for these conditions. |

|

From ASTM C926 the general intent to provide a sealant or

caulking material to seal out potential water entry at “V-grooves”, stucco

panel exposed ends and edges is clear.

The issue is identified and general requirement is explicitly stated. Significant support exists for the use

of sealant or caulk at weather-exposed lath accessories from every facet of

the stucco industry including the codified Minimum Stucco Industry Standard

ASTM C926, the original “control joint” lath accessory manufacturer, the metal

lath and lath accessory product manufacturer association, portland cement

product manufacturer organizations, contractor trade organizations, and

voluntary industry standards documents.

|

|

If every exterior stucco clad building surface

was fully-protected from the weather and direct exposure to bulk water

especially wind driven rain, then sealants or caulk related to the stucco

cladding system would probably not be essential for any exterior stucco wall

cladding system. A building would need

100% protection from the weather using extremely broad overhangs, a high

performance waterproofing enclosure system (basically an above ground

submarine) or similar means to be completely protected. But that is obviously not reality. Weather

reality is that many, many stucco clad buildings experience weather extremes

from time to time, if not on a regularly recurring basis. Even climates considered as relatively

benign, can experience occasional hard driving rains, windblown into the wall

claddings, buildings that may or may not have protective roof coverage or

other drainage conditions. Reasonably

designed and constructed solutions when it comes to exterior stucco wall

claddings will foresee and accommodate reasonably predictable extreme weather

conditions. Cured portland cement-based stucco wall

cladding systems are exceptionally weather-resistant, one reason that makes

them an excellent exterior building wall cladding system. Where water can potentially penetrate the exterior

stucco wall cladding is at discontinuities in the stucco cladding system – at

cracks, weather exposed and unsealed static and dynamic movement joints,

penetrations, wall openings and stucco panel edges. Cracks are not only visual

distractions; if a crack goes all the way through the stucco membrane it can

create a water pathway into the wall cladding system. Any crack that is visible at the finished

surface is a potential water path, but cracks may only occur on the surface

and not through the full thickness of the stucco membrane. A water molecule only needs a mil or two width to be able to penetrate through a crack. Cracks in one coat, may not align with

cracks in subsequent coats. Cracks in

one coat stucco applications may be more likely to be through cracks because

the coating has only one coating layer, than in a multiple coat stucco wall

cladding system. Multiple cementitous

coating layers add redundancy so cracks in 2-coat, 3-coat or 4-coat stucco

are more likely to be covered by succeeding coats. Minimizing water penetration at cracks is

in part, a function of the number of portland cement-based plaster coats and

characteristics of each coat, especially the finish coat. The potential for water penetration

into the stucco cladding system is a greater risk at weather-exposed

stucco lath accessory joint

splices, intersections, terminations, and at stucco panel edges than from

cracks. Rigid metal and plastic lath

accessories are exposed at the stucco finish surface and are commonly

installed with simple butted splices, intersections and terminations that are

not inherently watertight. Stucco

panel edges at perimeters, are typically constructed with casing beads, which

are not inherently watertight to the WRB or adjacent construction, and the

separation gap that occurs between the casing beads and adjacent windows,

doors, vents, penetrations and the interface with other claddings or wall

elements can allow water penetration if the gap is not sealed watertight. Water penetration into the exterior

stucco wall cladding system from any source is hopefully incidental moisture

only and not bulk water, but that depends on the specific combination of

weather conditions, weather exposures and construction of the exterior stucco

wall cladding system. Whether water

penetration occurs at cracks, lath accessories or stucco panel edges, a

concealed continuous WRB, SAF and sheet metal flashings and weep flashing

system is provided to manage incidental water and redirect it out of the

exterior stucco wall cladding system. Preventing bulk water from even

entering the stucco cladding system at all is by far the easiest, least

costly and most effective means of preventing water intrusion into the

building and avoiding the potential for concealed damage, than attempting to

manage it once it has bypassed the exterior stucco wall cladding. The strategic and careful application of

resilient sealant is the most effective, most durable solution and requires

no maintenance when concealed from ultraviolet exposure. Lath accessory splices, intersections,

terminations are best embedded into a sealant bed. Sealant at stucco panel edges with adjacent

dissimilar materials must unfortunately be exposed and periodically

maintained. Most dry lapped WRB and

flashings systems used with stucco wall claddings are dimensionally compact,

gravity drainage assemblies that may not have the performance capability to

effectively manage elevated volumes of water behind the stucco wall cladding

system because of their compact dimension.

Lath fasteners are jobsite installed and create innumerable fastener

penetrations in WRB membranes; any fastener penetrating the WRB that is

mis-located, mis-installed or removed without being repaired can potentially

allow water intrusion into the wall cavity.

Lath accessories are fabricated of metals and plastic, and extend

through the thickness of the stucco and are weather-exposed at the surface of

stucco. No lath accessory is resilient

enough or self-sealing to create a watertight condition at splices, intersections

and terminations without the use sealant or caulk. Stucco panel edges adjacent to

dissimilar materials such as at window and door frame assemblies, louvers and

vents, and wall penetrations require similar attention with sealant to create

a watertight condition. Window and

door frame assemblies sometimes include an “integral stucco stop” molded or

formed into their perimeter frames intended as a convenience to the

plasterer, but they are a disservice because they frequently do not function

as necessary to keep bulk water out of the stucco wall cladding. These window and door frame assemblies are

often made of aluminum or non-metallic materials, with a coefficient of

linear thermal expansion (CLE) that is quite different than stucco. The CLE of stucco and steel are similar,

but aluminum is 2x, and PVC is over 4x the CLE of

stucco. This difference in thermal

expansion rates creates an incompatibility between stucco and these other

materials under ambient service conditions which can create separation gaps,

stucco cracks and spalling which may allow water penetration at stucco panel

edges. Additionally, portland

cement-based plaster shrinks away from these perimeter conditions creating

similar gaps that can allow water penetration if not sealed or caulked

watertight. ASTM C1063 does not

recognize the ‘integral stucco stops’ of these assemblies as an acceptable

stucco panel edge termination, and requires a casing bead as a stucco panel

edge termination, a separation gap and a sealant joint at dissimilar

materials to prevent water penetration.

Avoid the temptation to omit casing beads and sealant at stucco panel

edges adjacent to dissimilar materials such as windows and doors, especially

assemblies with ‘integral stucco stops’.

Provide a separation gap between the stucco panel edge casing bead and

the dissimilar material of at least ¼ in. wide (3/8 in. and wider is a better

performance joint) and fill the gap with sealant over a backer rod following

ASTM C1193, for cleaning, joint configuration and other sealant joint

parameters. Other conditions of the exterior stucco

wall cladding system may exist that may allow water penetration but are not

explicitly mentioned as requiring sealant in ASTM C926. These conditions may require sealant or

caulking in the same spirit – to keep bulk water out of the stucco cladding

and out of the building. Lath

fasteners penetrating the WRB or SAF that miss framing members, or that are

installed at an angle or are otherwise mis-installed, or are removed and

relocated leaving an open hole in the WRB, may cause water penetration if not

sealed watertight. Drainage flashings

with unsealed laps or intersecting with other lath accessories may create

water pathways into the building if not sealed watertight. Sealant and caulking materials must be resilient,

durable and compatible with their substrate, typically either the metal or

plastic lath accessories or flashings, or the WRB membrane and SAF. Compatibility of materials must be

verified. Movement performance of sealant

must be verified. Substrate

preparation, cleanliness, the need for primers, sealant joint profile and

other factors must be considered and accommodated for the effective use of

sealant and caulking materials. The use of sealant materials is appropriate to seal

weather-exposed stucco movement joint lath accessory splices, intersections, terminations against potential water penetration. Stucco wall cladding system movement joints

provide a range of motion that is predictable and the movement joint can be

designed and sealant material specified to accommodate the required

movement. ¼ in. wide sealant joints

are the Minimum Industry Standard, but 3/8 in. and wider are easier to

install and perform better by accommodating more movement. Wider movement joint widths may be required

dependent on anticipated movement requirements. Sealant materials in correctly designed and

constructed stucco movement joint subassemblies can typically accommodate a

movement range of between 25% to over 100% of the joint width, so joint width

and sealant material performance capability are used to determine the design

of the joint and its performance.

Stucco movement joint subassemblies are located to accommodate various

movements – building substrate support movement, stucco panel perimeter

movement, movement at the interface between load-bearing and non-loadbearing

components, shrinkage movement and thermal movement, etc. The use of caulking materials is only appropriate for non-movement

conditions. Caulk materials are

relatively non-elastomeric, and can only realistically be used as a static hole filler where little to no movement is anticipated

which is one reason why caulking materials are not typically specified. Most design and construction professionals

will specify and use only one sealant material on the jobsite for the

purposes described, to avoid the potential for misapplying the wrong product

for the wrong purpose. While both

movement and non-movement conditions exist related to stucco wall cladding

systems, typically sealant materials are used for both conditions for

convenience, even though the movement capability of sealant materials are not

required for hole filling purposes.

Caulking materials will not be discussed further as they have limited

function and are seldom used. ANSI A42.2-1971, predecessor to ASTM C926, at A2.1.4 says: “On

exterior work, V-grooves shall be caulked or sealed to prevent entry of water.” ASTM C926 today, at A2.1.3, is virtually

identical, and adds “exposed ends and

edges of stucco panels or exterior work” to the requirements. The term ‘exterior’ is synonymous in definition with

weather-exposed surfaces in the building code. The concept is simple, exterior building

surfaces are weather-exposed and as such require weather protection. Non-weather exposed surfaces do not require

weather protection. That word “V-groove” is antiquated and troubling to some in a

contemporary context, but reflective of the terminology used in the era when

it was adopted. The 1981 HUD Minimum

Property Standards illuminates the term:

“Run V-groove on brown and

finish coats around all metal trim, and at similar conditions.” So a V-groove would have occurred in the

cement coats at metal lath accessories as it abutted adjacent components at

stucco panel ends and edges, a V-groove serves the same purpose and is

therefore functionally equivalent to a lath accessory today where exposed at

the stucco surface. A V-groove is

functionally identical to lath accessories which include conditions such as

intersections with other lath accessories, at splices, and such as where

wrapping internal and external corners.

Where occurring at weather-exposed surfaces, V-grooves and equating to

today’s lath accessory splices,

intersections, terminations, and stucco panel edges were then and are

now, prone to potential water penetration and required to be sealed to keep

bulk water out of the stucco cladding system. Water can potentially penetrate around the ends and edges of

stucco panels which occur at the top, bottom and sides of a stucco wall

cladding, around wall openings such as window and door assemblies, and at

penetrations such a pipes and electrical outlets. Each of these stucco conditions – joints,

joint terminations, and edges, must include a metallic or non-metallic lath

accessory and a separation gap to the dissimilar material to allow for

differential movement. The separation creates a stucco panel edge

and gap at the stucco panel edge which, at weather-exposed surfaces, needs to

be sealed to keep bulk water out of the stucco cladding system. Sealant applied

directly to portland cement-based stucco is not durable. Sheet metal and non-metallic lath accessories are hollow in

profile or create a hollow void behind them that even though potentially

narrow, is large enough to function as a water path. Once bulk water gets behind the lath

accessory it can travel great distances behind the stucco wall cladding until

it either drains out from behind the cladding or becomes water intrusion into

the wall cavity. It is important for

vertically-oriented lath accessories to allow drainage at their lowermost

termination, typically over weep screeds or drainage flashings – conditions which

should not be sealed to allow drainage. Fasteners for installing lath and lath accessories – nails,

screws and staples – can be especially challenging from a water penetration

perspective. On a wall, staple crowns

must be installed vertically-oriented parallel to studs so that both staple

legs are installed to penetrate vertical stud framing, which can be a

physical challenge for an installer.

Any fastener installed then subsequently removed leaves a hole in the

WRB that is a direct water path into the wall cavity unless it is

repaired. Seeing a black hole on black

building paper, through shiny, small lath apertures, and effectively sealing

them against water penetration, can be a challenge. Any fastener that is not set square to the

WRB surface, may go in misaligned and enlarge the penetration at the WRB

surface, may tear the WRB or may not seal to the WRB, etc. is a potential

water intrusion condition into the wall cavity. Fasteners that do not

self-gasket to the WRB surface may allow water intrusion; smooth shank

staples that miss substrate support framing are of particular concern. Fasteners that are not installed where they

penetrate the substrate support framing or blocking (‘shiners’) may allow

water intrusion into the wall cavity, even if they penetrate sheathing, which

is not acceptable purchase for fasteners as defined in ASTM C1063. Shiner fasteners may be abandoned in place,

and the fastener head domed with sealant to achieve a watertight condition,

or where removed, the remnant hole sealed watertight. ASTM D1970 is the industry standard

evaluation method for determining the self-sealability of fasteners through a

waterproofing membrane. While ASTM

D1970 is an informative test, it has limitations when used to evaluate stucco

cladding fasteners in typically encountered conditions found in stucco

cladding systems and is a reference resource but may not always be definitive

in emulating real world stucco wall cladding system conditions. In particular, it applies to smooth shank

nail fasteners not screws, installed only into plywood, with other particular

conditions, into a roof surface not a wall, and other factors. Embed lath accessory intersections, corners and terminations

into dabs of sealant or caulking which

minimizes long term UV exposure and hence degradation of the sealant or

caulking.

Avoid topical sealant application at lath accessories after the lath

accessories are installed. Applying

sealant or caulking topically after the

lath accessory is installed is not optimum because it may be difficult or not

possible at all to effectively seal the condition watertight, and exposure to

UV allows degradation and requires maintenance, and exposed sealant may be an

aesthetic issue. Concerning

water intrusion, a fundamental issue with stucco wall cladding systems where

lath is fastened with nails, screws or staples through a WRB to a substrate

support, is the multiple penetrations of lath fasteners through the WRB. Water finding its way behind the stucco

wall cladding system has been known to intrude into the wall cavity around

incorrectly installed fasteners, or when fasteners have been removed leaving

an open hole in the WRB, or if the fasteners miss framing members and other

vulnerable conditions in the WRB and flashing system. ASTM C926 recognizes that stucco wall

claddings are not inherently watertight and requires sealant or caulking at

exposed stucco wall cladding panel ends and edges to prevent the entry of

bulk water from getting behind the stucco cladding. Other potential water penetration

conditions through the stucco wall cladding include gaps created by shrinkage

and thermal movements around perimeter casing beads, extruded aluminum

terminations, intersections and terminations of SMJS, PMJS and BMJS and

sometimes stucco crack conditions.

Keeping the water out from behind the stucco cladding in the first

place is a significant factor in assuring a functional and reliable stucco

wall cladding system. The industry

recognizes that stucco wall cladding is not a watertight system in and of

itself and relies on the WRB, flashings and potentially a defined drainage

cavity to manage and drain water that does make it past the stucco wall

cladding system outer surface. With

regards to sealant or caulking for a stucco wall cladding system, determining

which entity installs and is responsible for this sealant or caulking causes

some consternation in the industry.

One issue is that ASTM C926 requires sealant or caulking at certain

stucco wall cladding perimeter conditions, yet sealant and caulking may be a

separate trade from the plastering trade.

Secondly, sealant or caulking may be required at certain conditions

within the stucco cladding system yet ASTM C926 and C1063 are silent on these

conditions. The solution to this

sealant dilemma reflects a combination of the location of the sealant in

question, contractual responsibilities, and the expectations and actual

performance and workmanship quality of the stucco wall cladding system. It

is generally accepted within the industry that the stucco wall cladding

craftsman is responsible for any sealant or caulking needed that is related

to the installation of the stucco cladding system particularly at lath

fastener penetrations of the WRB or repairing damage caused to the WRB

resultant from installing the stucco wall cladding system over the WRB. Frequently the stucco wall cladding

craftsman also installs the WRB at stucco conditions so it is appropriate

that sealant at these conditions be within the stucco wall cladding

craftsman’s customary scope of work.

Likewise it is customary practice that any required sealant or

caulking within the stucco wall cladding perimeter such as at BMJS, PMJS, and

SMJS ends, intersections and terminations, sheet metal flashing laps, etc.,

is also within the purview of the stucco wall cladding contractor, where it

is true that the stucco craftsman installs these components and

subassemblies. ASTM C926 directly recognizes the importance of sealant

or caulking at the stucco wall cladding system perimeter (panel ends and

edges) as an essential functional component for the stucco wall cladding

system where it adjoins with dissimilar materials by specifying sealant or

caulking at these conditions. ASTM

C926 however, does not specify the entity responsible for installing sealant

at stucco panel ends and edges. ASTM

C926 is a reference specification, similar to contract specifications

prepared following Construction Specifications Institute (CSI)

specifications. Specifications in a

project manual, whether they be Sections in a project manual or codified

reference specifications as in ASTM Standard Specifications, specify a ‘unit

of work’ – e.g. the work required, but not an identification of the specific

entity responsible for executing the work, other than the contracting party

of the general contractor. The point is that any party can be contractually

responsible for the sealant and caulking occurring at the perimeter of the

stucco wall cladding system, a determination just needs to be agreed

upon. One precedent for determining

responsibility is realizing that perimeter sealant or caulking is an integral

component of other non-stucco wall cladding exterior wall-related systems

materials and their installers – e.g. metal panel cladding, windows, curtain

walls, doors, plumbing and electrical penetrations, etc,

so the same approach could be applied to the stucco wall cladding

system. An issue with this approach is

that most stucco craftsmen are not trained or experienced in the sealant

joint trade and know their limitations and there may be trade boundaries or

licensing issues. To provide the

perimeter sealant joints, some projects will engage a separate dedicated

sealant subcontractor for sealant work for the entire project other than

where sealant or caulking occurs within separate individual systems. On other projects, for contracting

convenience, warranty management and other reasons, sometimes general

contractors will assign the sealant and caulking related to a given system to

the relevant subcontractor. This is

not generally an unreasonable practice it is simply a matter of

contract. Where the stucco craftsman

is required by contract to provide perimeter sealant, if not personally

qualified or willing to self-perform the sealant or caulking work, and if

allowable by trade and licensure laws, it is within their prerogative to

subcontract for the sealant and caulking with qualified entities to comply

with their contract. The following images represent a few examples of some of the

more common conditions that can allow bulk water intrusion into, around and

through a stucco wall cladding system, and

potentially into a wall cavity that require sealant or caulking or other

effective repair method to maintain watertight integrity of the stucco wall

cladding system. These examples are

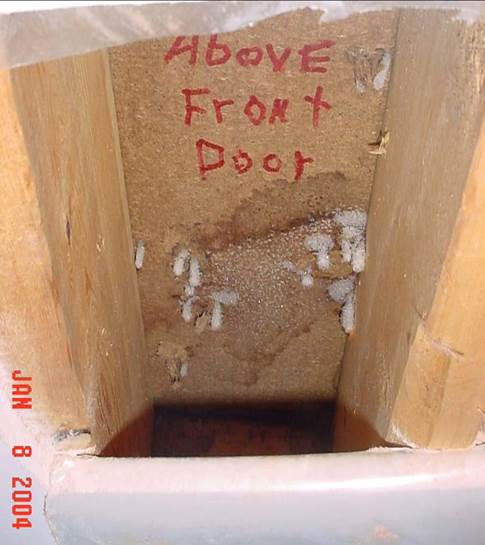

not a comprehensive list: Holes At Removed Lath Fasteners in WRB

Empty holes through WRB at removed lath fasteners

Removed lath fastener through OSB sheathing between framing

members. Water testing in process

without differential pressure. Staple leg shiners allowing water intrusion Testing in process without differential pressure (Click photo to see

video)

Staple leg shiner installed between framing members. Gypsum sheathing does

not effectively gasket fasteners Water testing in process

without differential pressure.

Lath fastener installed into framing member, but not drawn

tight to WRB Lath

fasteners not in compression can allow water intrusion. Water testing in process

without differential pressure.

Staple leg shiners at 7/16 inch thick OSB sheathing 3/4 in. embedment into

framing members is not achieved as

required by ASTM C1063

Lath fastener shiners in wood based sheathing can allow water

intrusion Photo courtesy of

Paul Ellringer PE, CIH, www.airtamarack.com

Lath fastener shiners in cold climates can allow condensation Photo courtesy of

Paul Ellringer PE, CIH, www.airtamarack.com A variety of solutions exist to address lath fastener-related

conditions, depending on the circumstances.

The following images generally illustrate potential solutions,

although the list is not comprehensive:

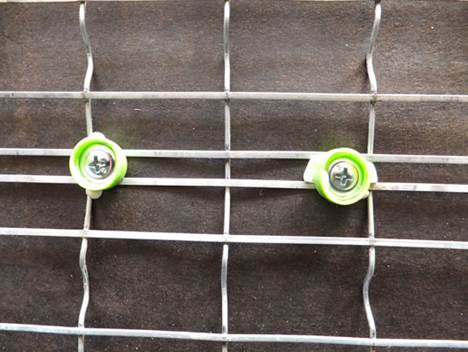

Lath nails with furring wads, provides gasket to WRB

Sealant at lath fastener screw heads, provides gasket to WRB

Proprietary screws with sealant-filled furring device provides gasket to WRB (Photo courtesy of Greg

Stephan of Fasten Seal Products LLC) Gaps At Weather-Exposed Trim Splices, Intersections,

Terminations

Unsealed lath accessory splice is a potential water path into

the wall cavity. Mock-up wall omits WRB for visualization

purposes. Water testing in process

without differential pressure. (Photo courtesy of

www.RobertTellez.com of Roberts Consulting Group)

Unsealed lath accessory intersection is a potential water path into the wall cavity

Unsealed BMJS subssembly intersection is a potential water path into the wall cavity

Unsealed lath accessory termination is a potential water path into the wall cavity

Embed lath accessory splices,

intersections, terminations into sealant, avoid topical sealant application (photo

courtesy Jim Gulde, Masonry Information

Technologists, Inc.)

Sealant applied to intersection of window head Z-flashing (no

end caps) and top end of vertical window jamb casing bead

Sealant applied at intersection of EATS reveal and vertical window jamb casing bead.

Sealant applied at intersection of Double-V Horizontal

Drainage screed and vertical window jamb casing bead

Sealant applied at intersection of vertical SMJS subssembly

and upper horizontal casing bead at stucco panel edge

Horizontal SMJS subssembly splice embedded in sealant bed

Horizontal SMJS subssembly terminations embedded in sealant

bed

Sealant applied at lap splice of drainage screed, Where placed over wall assembly below

Unsealed

lowermost vertical lath accessory termination at

horizontal drainage screed to allow drainage

Stucco panel edge (without casing bead or sealant) at

dissimilar materials is a potential water path into the wall cavity Arrow pointing to

unsealed gap

Stucco panel edge (without casing bead or sealant) at

dissimilar materials is a potential water path into the wall cavity Arrow buried into unsealed gap

Sealant filling separation gap between stucco panel edge

casing bead and window assembly (dissimilar material)

Gap and sealant between stucco panel edge sheet metal flashing and pipe penetration (dissimilar material) Sealant Used for Decorative Purposes Disappearing joints: Sealant may also be used for exposed,

decorative purposes. Stucco wall

cladding system movement joints including BMJS, PMJS and SMJS are needed for

functional reasons and they should be located wherever they need to be

located for functional purposes to minimize stucco cracking – as the primary

and foremost rationale. Because joints

are visible at the stucco surface, they create narrow shadow lines that some,

in certain situations, would prefer to not see, especially in common, perfectly

planar, smooth stucco surfaces. ‘I

don’t want to see joints – make them go away’ you say! The linear gaps at these subassemblies can

be filled with a small backer rod and sealant to minimize the visibility of

the joints, for decorative purposes if desired – and voila! – they disappear before your very eyes. Well almost disappear, and it can be pretty

convincing especially if you squint - but you get the idea. The sealant should be pre-tinted to match

the adjacent stucco color and not painted over, because painted sealant will

crack due to joint movement. All the

typical requirements for sealant apply – clean and prime the substrate, and

correctly tool the sealant. Sand can

even be embedded into the sealant to approximate the stucco finish texture

and reduce sealant gloss if desired. The

exposed sealant will not make the SMJS shadow lines completely disappear, but

this approach will minimize their visibility. Celebrate the joints:

Alternatively, stucco wall cladding movement joints can also be used

to express the function of the discrete panels and to visually segment and

organize a building elevation. Imagine

stucco cladding that looks like precast concrete or GFRC panels on that new

commercial, institutional or luxury residential building in the downtown

core. With careful attention to joint

location, detailing, finish coat material and texture selection, stucco can

be panelized to emulate precast concrete and GFRC wall claddings, both of

which require sealant joints at panel perimeters. Precast concrete and GFRC are considered by

some to be more desirable wall claddings than stucco, this is an opportunity

for stucco to shine and recapture market share. A consideration of this approach is that exposed sealant will

eventually deteriorate and require periodic maintenance or replacement, but

this is true of any exterior wall cladding system that includes sealant at

joints – stone, precast concrete, GFRC, metal panels, etc. The difference is that these other claddings

depend on sealant as a critical component

of the cladding system that protects the building from water intrusion. With stucco, exposed sealant used for

decorative purposes to fill movement joints is not a critical component of

the stucco cladding system for avoiding water intrusion. The use of more articulated, non-smooth surface, profiled

textures is another approach also minimizing the visibility of stucco

movement joints.

Color-matched, sealant-filled vertical SMJS pleats over horizontal EATS channel

Color-matched, sealant-filled SMJS subssembly pleats disappear almost completely

A great example of using color-matched, sealant-filled SMJS subssembly pleats (top of photo), as compared to non-sealant filled pleats (bottom of photo). |

|

Weather exposed stucco panel edges, wall openings at windows,

doors and penetrations, similar conditions, gaps at trims and certain lath

fastener conditions may create water pathways that may allow water intrusion. Exterior stucco wall cladding systems at

weather exposed surfaces require sealant or caulking, applied with reasonable

care and concealed where possible, in strategic locations to keep bulk water

out of the exterior stucco wall cladding system. A

single sealant material is typically used for both movement joints and

non-moving conditions which are the primary materials for sealing potential

water pathways for minimizing bulk water penetration into the exterior stucco

wall cladding system. Silicone sealants

generally provide the greatest movement capacity and long term

serviceability, but other sealant materials are available. Holes At Removed Lath Fasteners in WRB Holes

in the WRB are potential water pathways and must be sealed watertight Shiners

in the WRB are potential water pathways and must be sealed watertight Gaps At Weather-Exposed Trim Splices,

Intersections, Terminations Gaps at

weather-exposed trims are potential water pathways and must be sealed

watertight Gaps at

stucco panel edges are potential water pathways and must be sealed watertight Sealant Used for Decorative Purposes Sealant

used to conceal stucco movement joints is discretionary |

|

Provide sealant or caulking, applied with reasonable care and concealed

where possible, in strategic locations at weather exposed stucco panel edges,

wall openings at windows, doors and penetrations, similar conditions, gaps at

trims and certain lath fastener conditions to seal potential water pathways

that may allow water penetration. Specify

and use a compatible, durable sealant material, with sufficient movement

capability for both movement joints and non-moving conditions. Holes At Removed Lath Fasteners in WRB Stucco

Minimum Standard of Care: Inspect 100% of the WRB during and after

lath and lath accessories are installed for removed fastener holes and seal

holes watertight. Stucco

Best Practice: Water test 100% of the WRB after lath and lath accessories are

installed to locate obvious or potential water pathways to minimize water

penetration. Stucco

Minimum Standard of Care: Inspect 100% of wall cavity surfaces for

lath fastener shiners after lathing and lath accessories are completely

installed. Remove loose shiners and

seal holes at WRB watertight. Stable

shiners that create a reliable compression condition with the WRB can be

abandoned in place, but should be sealed at the WRB watertight, except in

cold climates subject to condensation where shiners should be removed and the

remnant hole sealed watertight. Stucco

Best Practice: Remove shiners and seal holes at the WRB watertight. Seal all lath fasteners at the WRB or

specify and use proprietary lath fasteners that include an integral sealant. Gaps At Weather-Exposed Trim Splices, Intersections,

Terminations Stucco

Minimum Standard of Care: ·

At lath accessory butt splice

conditions, provide splice plates, end caps and prefabricated intersections

that can be sealed watertight where available for lath accessory

profiles. ·

At weather-exposed surfaces, seal

stucco movement joint (BMJS, PMJS, SMJS) and decorative joint splices, intersections,

terminations watertight, to minimize bulk water penetration behind the

stucco wall cladding system. Embed exposed

lath accessory splices,

intersections, terminations in a thick sealant daub to conceal the sealant as

the lath accessories are installed. Avoid topical sealant application at lath accessories

after the lath accessories are installed. ·

Stucco

Minimum Standard of Care: Seal lap splices of drainage screeds and

flashings, where water penetration through the lap splice may allow water

penetration into the wall cavity. ·

Stucco

Minimum Standard of Care: The ground facing end of vertically

installed lath accessories should not be sealed when terminating into a

horizontal drainage flashing weep screed or drainage Subssembly, to allow

drainage. Stucco Minimum Standard of Care: ·

Avoid using the ‘integral stucco stop’

such as may be provided with window and door assemblies. Provide a

casing bead, separation gaps and sealant over

backer rod at stucco panel edges from the perimeter casing bead to adjacent

dissimilar materials such as at window and door assemblies, vents, ducts,

equipment and penetration, flashings at electrical boxes, etc. ·

Follow ASTM C1193

requirements for sealant joints design and installation, which specifies the

minimum dimension width for a sealant joint as ¼ in., with the caution that this

is a difficult width sealant joint to install and provides minimal movement

capability. Provide substrate surface

preparation, backer rod and tooling for correct hourglass shape. Stucco

Best Practice: Provide 3/8 in. minimum dimension width or wider separation

gaps for sealant joints. Sealant Used for Decorative Purposes To

minimize the visual impact of exposed stucco movement joint subassemblies,

consider filling them with sealant over backer rod for decorative

purposes. |

|

(1)

ASTM

International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA

19428-2959. United States (2)

ANSI A42.2-1971 Portland Cement and Portland Cement-Lime

Plastering Exterior (Stucco) and Interior (3)

Technical Manual, Keene Corporation, Penn Metal

Products, undated, c.1980 (4)

Exterior Lath & Plaster Control Joints,

Planned Points of Stress Relief, Western

Conference of Lathing and Plastering Institutes, Inc.(WCLPI), undated, c.1980 (5)

Minimum Property Standards, US Department of Housing and Urban

Development (HUD), 1981 (6)

Keene Corporation

product catalog, 1983 (7)

Guide Specifications for Metal Lathing

and Furring,

920-91, Metal Lath/Steel Framing

Association (ML/SFA Division of NAAMM), 1991 (8)

Guide to Portland Cement Plastering, ACI 524R, American Concrete Institute,

1993 (9)

Portland Cement Plaster (Stucco)

Manual, EB049

Portland Cement Association, 1996 (10)

Stucco Resource Guide, Northwest Wall Ceiling Bureau, 1997 (11)

Stucco Resource Guide, Northwest Wall Ceiling Bureau, 1999 (12)

Systems Manual, Texas Lathing and Plastering

Contractors Association & the Texas Bureau for Lathing and Plastering,

2001 (13)

Portland Cement Plaster (Stucco)

Manual, EB049

Portland Cement Association, 2003 (14)

Guide to Portland Cement Plastering, ACI 524R, American Concrete

Institute, 2004 (15)

Stucco in Residential Construction, Minnesota Lath and Plaster Bureau,

2007 (16)

Guide to Portland Cement Plastering, ACI 524R, American Concrete

Institute, 2008 (17)

AMICO product catalog, 2009 (18)

Guide Specifications for Metal Lathing and

Furring, EMLA 920-09,

2009 (19)

Lath Inspection Resource Manual, Second Edition, Minnesota Lath &

Plaster Bureau, 2009 (20)

Plaster Assemblies Manual Online, Technical Services Information

Bureau (TSIB), 2011 (21)

Fasteners and Self-Sealability of

Weather-Resistive Barriers, RCI-TA-005-2014, Roof Consultants Institute

Technical Advisory, 2014 (22)

Plaster & Drywall Assemblies

Manual, Walls and

Ceiling Magazine, 2014 |

|

Consultation with licensed and experienced stucco professionals is

recommended for stucco-related endeavors.

No liability is accepted for any reason or circumstance, specifically

including personal or professional negligence, consequential damages or third

party claims, based on any legal theory, from the use, misuse or reliance

upon information presented or in any way connected with StuccoMetrics.com. |

Home Page Contact Me Disclaimer