|

StuccoMetrics® |

Jeff Bowlsby CCS, CCCA

Exterior Wall and Stucco Consultant

Licensed

California Architect

Stucco Finish Coat Texture

|

Webpage Quicklinks |

|

The stucco finish coat can be used to create

a finish texture or pattern which can be an important characteristic of how a

stucco installation is perceived, experienced, performs and is evaluated. Visit the StuccoMetrics Reference Archives

webpage for cited references and further information. |

|

In

the past, in some but not all regions, the term ‘stucco’ may refer to the

finish coat only or to other meanings.

Other connotations refer to ‘stucco’ as exterior cement plaster and

‘plaster’ as interior cement plaster.

This website construes the term ‘stucco’ more broadly, to include the

complete portland cement plaster cladding system, for exterior building

applications. Minimum

Stucco Industry Standards for stucco wall cladding systems are indicated below.

Readers are encouraged to purchase the referenced

ASTM Standards directly from ASTM and review them. The referenced ASTM Standards and texts are

indicated for reader’s convenience, for purposes of topical discussion. Requirements

of the Standards are paraphrased, written in the imperative mood and

streamlined writing format as is recommended by the Construction

Specifications Institute (CSI) and common to construction specifications,

using the terminology developed and described on StuccoMetrics.com. ASTM C1063 Standard

Specification Installation for Lathing and Furring to Receive Interior and

Exterior Portland Cement-Based Plaster(1) ·

(7.1) Workmanship: Erect metal furring and plaster bases to

receive specified plaster thickness and achieve finished stucco surfaces true

to line within 1/4-in. (6.4-mm) in 10-ft (3.05-m), level, plumb, square or

curved as designed. ASTM

C926 Standard Specification for

Application for Portland Cement-Based Plaster(1): ·

(3.2.10.2) bedding coat: a plaster coat for embedding aggregate or

other decorative material as an exposed finish. ·

(3.2.10.6) finish coat plaster: Final, exposed plaster layer ·

(3.2.15) factory-prepared plaster: Factory-prepared dry-blended proprietary

plaster material combinations, requiring only adding water and mixing before

application. ·

(3.2.17) floating:

The process of either using a float tool to densify, level and

reasonably true the brown coat plaster, or bringing the aggregate to the

surface of finish coat plaster. ·

(3.2.27) stucco finish: Factory-prepared dry-blended proprietary

plaster material combinations, for finish coat plaster applications. ·

(3.2.29) texture:

Any plaster surface profile other than a smooth surface ·

(4.4.3) Sand, jobsite mixed finish coat

plaster: Specification C897 ·

(6.1.2) Plaster mixes are symbolized as a function

of the base over which they are applied: Specified in Table 1 ·

(6.1.4)

Mixture proportions, jobsite mixed finish coat plaster: Specified in Table 3. ·

(6.1.5)

Factory-prepared finish coat plaster:

Reference 3.2.15. ·

(6.2.3) Finish coat plaster: Retempering not

allowed. ·

(7.1.2) Plaster nominal thickness: Measured from outer plaster surface

exclusive of texture variations, to either back plane of metal plaster base

exclusive of self-furring provisions, or to outer surface of WRB or solid

plaster base. ·

(7.2.3) Apply finish coat plaster with sufficient

material and pressure to assure continuous bond, coverage of base coat and

nominal thickness required by Table 4 and 7.3.1.1. ·

(7.3.2.3) Three-coat work: Apply finish coat plaster following 7.2.3 ·

(7.3.3.2) Two-coat work: Apply finish coat plaster following 7.2.3 ·

(7.4.1) Finish coat plaster, either jobsite mixed

or factory-prepared: Apply by machine

or by hand, following 7.2.3. ·

(7.4.2) Avoid excessive water use while applying

and finishing finish coat plaster. Appendix X1.2 (Nonmandatory

Information) Finish Coat Categories (applicable to both natural and colored finishes): ·

(X1.2.1-X1.3): Narratives describing a variety of

textures. |

|

Why is it in contemporary

American architecture where stucco is a predominant exterior wall cladding

material, that it is most often used to emphasize a flat, planar, uniform, soul-less

surface? It is often placed over

irregular substrates, adjacent to other materials that are extruded,

machined, cut or fabricated with high precision for linearity and planarity. In that visual context, it is natural to

visually compare stucco to those other materials, i.e. with the expectation

of as much linear and planar precision as possible. The demand is strong especially in modern

architecture, for a machine-like, smooth trowel finish that emulates plaster

over masonry, with no cracks and no joints. |

|

Stucco bases including

solid masonry walls of brick or concrete masonry units, cast concrete, or

scratch/brown portland cement plaster over lath, are in and of themselves durable

materials that with minimal maintenance should remain serviceable for the

life of any building. However, when

exposed, these materials are subject to weathering and deterioration, and

sometimes these materials are not attractive aesthetically. A stucco finish coat can be installed over

bases which enhance the aesthetics and coloration of the building and improve

durability by functioning as the exposed layer of protection against

water-related deterioration. Texture

is an articulation of the exposed stucco finish surface and only occurs in

the stucco finish coat. This webpage focuses on the

textural possibilities available for stucco.

Architects realize that textures can be an important aspect of the architectural

expression, tactile experience and sculptural qualities of a building. Finish coat texture selection and

specification can be an important factor when desiring that the visibility of

stucco cracks and base coat surface

imperfections be concealed.

Cracks can be more noticeable with smooth finish textures, and are

less noticeable with more heavily articulated finish textures. To pursue and achieve that

perfectly flat, planar, joint-less, crack-less stucco finish coat aesthetic

is an admirable goal but far from reality.

The vast majority of substrate construction in the USA is not masonry,

a substrate that has few if any joints, but framed construction which

requires stucco with movement joints for performance reasons. Acknowledging the preference

for smooth stucco surfaces in certain contexts, it is also important to

realize that our buildings can benefit by expressing the unique fluid,

plastic qualities of stucco in other settings. Portland cement-based plaster is a fluid,

plastic material when it is installed, and it is within its nature to express

its fluid, plastic qualities, even more so than when used as a flat

plane. Stucco can be used to clad an

entire building, or portions of a building for aesthetic or architectural,

compositional effect. A range of

different textures can be used on the same building, with aesthetic

discretion, for various aesthetic effects. Textural possibilities are

limited only by the imagination and variations in the finish coat application

methods, tool selection and materials used.

Textures from the smoothest surfaces (including metallic emulations),

to fine-, medium-, and coarse- grained textures, to embossing, scoring, and

finally to three-dimensional sculptural effects that are molded integral with

the wall but project from the wall.

Textures are influenced by the selections of materials used such as

aggregate type, size and density.

Small dimension aggregates typically result in smooth finishes, coarse

aggregates allow heavy articulation.

Aggregates can be mixed into the finish stucco matrix or embedded by

casting onto a bedding coat.

Decorative inorganic exposed aggregates can be implemented for a

variety of effects – glass fragments and beads, glazed tile, mica flakes,

stone chips, sea shells, crushed pebbles and small gravel – what other

materials can be used? Stucco finish coat

materials consist primarily of an aggregate which provides durability and

color, a binder which adheres to the aggregate and stucco base, and often an

integral pigment or pigmented surface coating. To be durable, aggregates must not be

adversely affected by water (non-ferrous) or by alkalis from the stucco base

or binder. Aggregates may include

silica sand, marble, granite and similar inert materials of various gradations. Aggregate gradations range from the finest

granularity (almost a powder) for smooth finishes to small dimension gravels

for the coarsest, most articulated, tactile textures. Stucco finish coat binders can be portland

cement-based, lime-based or polymer-based and durability is primarily

determined by the binder material characteristics. Portland cement-based finish coat binders

are durable and common, whether they include integral pigments or are

painted. Lime-based finish coat

binders were the traditional finish coat material until portland cement

became more abundant and popular, but remain available. Polymer-based (typically acrylic) finish

coat binders, as a carry-over from the EIFS industry, are becoming prevalent

in contemporary construction. Each of

these different finish coat materials has different aesthetic and performance

characteristics. Not all textures can be created using each different binder

material. Textures are also influenced by the installation techniques and

tools used by craftsman. Stucco finish coats may be simply trowelled

or sprayed on and textured during installation. Smooth surface trowels, steel and

plastic, result in smooth finish textures, sponge and wood floats create

rougher textures. What other tooling

can be used to create desirable, unique pattern or texture variations? With imagination, implementing a variety of

interesting finish textures in addition to the standard sand float and

spray-on knockdowns that are so common, can be explored and implemented. Make the stucco finish texture an important

aesthetic feature of the spatial experience.

Use your imagination. Be

creative.

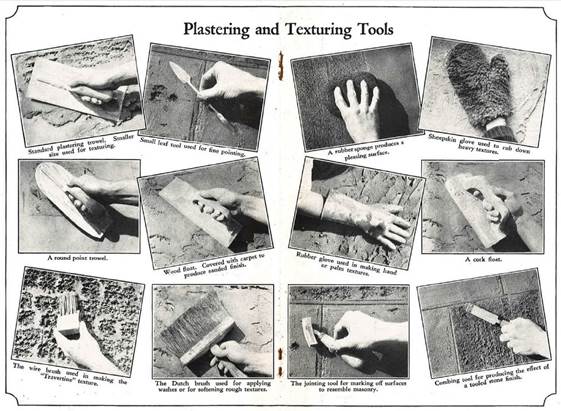

Plastering and Texturing Tools From Plasterer’s Manual P21, Portland Cement

Association, 1948(2) Photo used with permission of the Portland Cement

Association

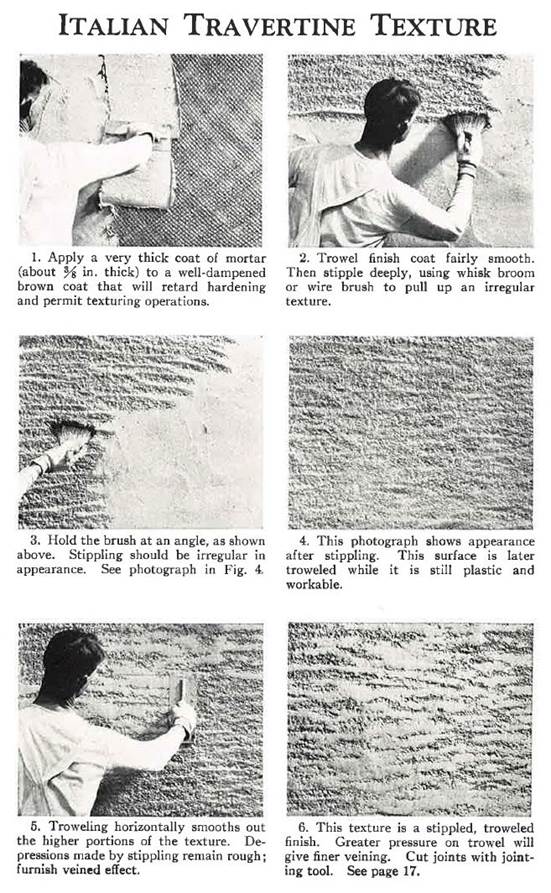

One of several illustrated texturing techniques From Plasterer’s Manual P21, Portland Cement

Association, 1948(2) Photo used with permission of the Portland Cement

Association Anticipate

that manually-applied finish texture coats will not be perfectly uniform as

when produced with machine assistance.

Variances in manually-applied finish coats are germane to its

character and artistic expression. A

higher level of artistic craftsmanship is required for the most creative

textures. Artistic expressions of

stucco finish textures by imaginative and experienced craftsman can include

emulated naturescapes with rocks, boulders,

naturalistic stone outcroppings, tree trunks, roots, which can integrate

water features, creeks, streams, waterfalls and landscaping materials. Stucco can be an excellent emulation media

for stone and specialty naturalistic environmental settings and where

integrated with a building design can become “one with nature”. More

sophisticated decorative patterns and effects similar to Venetian plasters

such as Sgrafitto may be possible using portland

cement plasters. It is time to

experiment. |

|

Stucco finish coat textures are an important

tool for aesthetic expression and are virtually limitless in variation. |

|

GENERAL Minimum Standard of Care: Architect specifies the required

stucco texture or specifies which entity selects and approves the stucco

texture, which could be the owner, the architect, the installer or another

entity. Stucco Best Practices: ·

Architect specifies finish coat material and texture requirements by including

a physical sample or a photo (use the images from this website or other

resource) and inserting them onto the construction drawings or

specifications. ·

Architect specifies that mock-ups of the required finish coat material

and texture be submitted for review and approval on a free-standing mock-up

on site, before installation. An

accepted mock-up becomes the standard to judge installed work. ·

The stucco craftsmen must understand the specified finish coat material(s)

and texture(s) and the requirements necessary to achieve the specified

results during bidding and submits the texture for review and approval before

installation. ·

Select medium to rough textures to minimize the appearance of

cracks. Cracks and base coat surface

imperfections appear more noticeable in smooth trowel finishes, than in

heavier textures. PRODUCTS Stucco

textures can include a full array of not only artistic workmanship based texturing

techniques, but also embedded and exposed aggregates, mica, glass, embossed

patterns – the possibilities are almost endless. Experimentation is suggested, to explore

the possibilities for architectural expression. INSTALLATION Stucco Best Practice:

Where more than one stucco craftsman applies the texture on a project,

practice and coordinate the installation to minimize and avoid visible

variations in the texture. |

|

References (1)

ASTM

International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA

19428-2959. United States (2)

Portland Cement Association, 5420 Old Orchard Road, Skokie, IL 60077-1083 |

|

Consultation with licensed and experienced stucco professionals

is recommended for stucco-related endeavors.

No liability is accepted for any reason or circumstance, specifically

including personal or professional negligence, consequential damages or third

party claims, based on any legal theory, from the use, misuse or reliance upon

information presented or in any way connected with StuccoMetrics.com. |

Home Page Contact Me Disclaimer