|

StuccoMetrics® |

Jeff Bowlsby CCS, CCCA

Exterior Wall and Stucco Consultant

Licensed

California Architect

Stucco Submittals & Shop Drawings:

Merging the Art and Craft of Stucco

|

Webpage Quicklinks Stucco shop drawings directly

benefit the architect, owner and the project Stucco shop drawings directly benefit

stucco craftsmen What are stucco shop drawings? Who should prepare stucco

submittals and shop drawings? |

|

Stucco

can be a paradox. While on the one

hand stucco appears inert and low-tech and primarily brings certain aesthetic

qualities to a building, today’s stucco wall cladding is an increasingly

technically complex and dynamic system of generic and proprietary components

and systems combined in various ways that are constantly developing each

day. Consider that a stucco wall

cladding system may be installed by several different trades, interfaces with

a plethora of other adjacent systems, assemblies and components, and all that

requires considerable coordination.

Gone are the days when one can simply hire a plasterer to ‘put on the

stucco’ and everyone will be happy.

The more complex things are in construction, the greater the

possibility of complications, unsatisfied expectations and even failures. Submittals

and shop drawings are standard and effective quality assurance and quality

control practices implemented early in the building construction process that

ultimately benefits a construction project as a coordination tool. The construction industry routinely

implements submittals and shop drawings for other complex systems including

curtain walls, window/door systems, mechanical systems, structural steel

framing, sheet metal flashings, roofing systems, precast and GFRC wall claddings,

casework, paving and flooring, and other disciplines. Specifying and completing a submittals and

shop drawings process as a requirement for stucco is not only appropriate for

any project with stucco, it should be a necessity considering the realities

and demands of today’s construction environment. Visit the StuccoMetrics Reference Archives

webpage for cited references and further information. Acknowledgement

to my colleague Robert Bateman, AIA at Simpson, Gumpertz and Heger, for the

suggestion of implementing a shop drawings approach in the stucco design,

contracting and delivery process. |

|

Significant

precedent exists in the building construction environment supporting the value

of submittals and shop drawings to complex systems that require coordination

with other work on a jobsite. Bottom

line is that owners and architects can be pretty focused on the qualities,

characteristics and detailing of the stucco, because it is a permanent

finish. Those closest to stucco

installation can provide through shop drawings and submittals, the benefit of

their technical experience with materials and detailing to benefit the stucco

system installation with a level of detail beyond what the design

professional of record typically is knowledgeable about or provides. However, the stucco industry has little

experience with the benefits and requirements of shop drawings for stucco

cladding system. |

|

Stucco is a complex exterior wall cladding

system replete with high expectations for aesthetics, performance and

durability from every stakeholder with an interest in stucco. Stucco is a system of generic products and

materials provided by various different manufacturers, site assembled in

weather-conditions that are sometimes challenging to providing the best

results. In

part, stucco depends on systems provided by others to succeed. Framing, substrate and perimeter

conditions. Windows, doors and louver assemblies. Pipe penetrations. Copings, eave gutters and flashings. The WRB and drainage provisions. Jobsite coordination for material staging,

scaffolding and utilities, clean-up.

The communication and coordination of stucco’s requirements are essential

if stucco is has any chance of meeting its objectives and expectations. |

|

If

you are reading this, you are undoubtedly familiar with stucco cladding

installations on a detailed level. Can

you imagine designing, constructing and evaluating a curtainwall, structural

steel framing, precast concrete, GFRC, cabinetry or other complex

construction system without good, complete, coordinated construction

drawings, specifications, submittals and shop drawings? That is an absurd proposition and recipe

for disaster. Why should stucco as a

complex system, as interrelated with other complex systems as it is, be

approached any differently? Specified

or otherwise provided stucco submittals have traditionally been extremely

basic and stucco shop drawings virtually non-existent on most construction

projects. The stucco industry at large

is not familiar with or adept at preparing shop drawings, or of the shop

drawing submittal and review process.

This is a significant weakness in the stucco industry and will be a

requirement, near-term, for the stucco industry to survive, thrive and be

competitive with other exterior wall cladding systems. Stucco shop drawings directly

benefit the architect, owner and the project: Using

limited plan notes and details for stucco may not and probably will not yield

satisfactory results except on the most rudimentary of projects with minimal

expectations. For smaller projects it

is common to include only limited information such as a few notes on the

drawings like “7/8 in thick, 3-coat stucco with acrylic finish”, and minimum

detailing with casing beads, SMJS subassembly locations and a weep screed,

maybe, if you are lucky. You are on

your own with this approach, guessing and assumptions are involved about

everything else required, and it may not be defensible if differences of

opinion or other problems arise. Take

what you get with this approach, because this stucco installation will likely

not be completely satisfactory. The

traditional approach to stucco design absorbs a significant portion of

architectural fees for detailing and specifications, increases liability and

may not be correct or satisfactory.

Traditionally, the architect sets out to design every aspect of the

stucco cladding system, providing multiple construction details, specifying

materials and requiring a few submittals.

Virtually every set of architects drawings and specifications I peer

review that uses this approach has significant conflicts, inaccuracies and

technical errors and are often incomplete or silent regarding important

requirements for stucco. This approach

may not meet an architect’s professional standard of care if not reviewed and

resolved before issuance for construction.

It is common to see everything from the specification of obsolete or

unavailable materials, defunct manufacturers and out-of date reference

standards, incorrect details, conflicts with Minimum Stucco Industry Standards,

lack of clarity for finish and texture, and more. Stucco has become complex and this is not

an effective or optimum approach for most architects that require the best

results from stucco. Architects

generally don’t design other complicated systems to this level, so this

approach leaves the architect assuming significant risks and likely stucco

that will not be acceptable. Some of

the issues typical stucco practice without shop drawings does not address are

conditions often left to the installer such as: 1.

Are weep screed splices and

corners dry-lapped or sealed watertight? 2.

How does a weep screed terminate

at a hollow metal door jamb or at a projecting balcony corner-to-wall? 3.

How does a casing bead at a

window jamb intersect the window head flashing? 4.

How are lath accessories detailed

at window/door recesses? 5.

Are casing beads used as

flashings and integrated into the WRB? 6.

How are SMJS and BMJS

subassemblies installed to assure their function? 7.

What lath accessories and

detailing are needed at electrical/mechanical penetrations, at surface

mounted utility boxes etc., and how does the location of these items

coordinate with other components? 8.

If, how and under what conditions

are shims at lath accessories used? 9.

How are extruded aluminum lath

accessories fastened, how do they intersect, splice and terminate, and how is

thermal expansion/contraction accommodated? 10.

How are shiner/spinner lath

fasteners inspected and addressed? 11.

What are the criteria for

evaluating the acceptability of cracks, planar tolerance of the substrate and

finish, and color and texture uniformity? 12.

How does the stucco system and

its assemblies, subassemblies, components and its interface with adjacent

systems such as thickness build-ups at flanged windows and waterproofing? 13.

What are owner maintenance

requirements? 14.

And much more… The

approach of involving a professional stucco consultant can be a good and cost

effective solution. The traditional

design approach as above can be more effective with the involvement of a professional

stucco consultant during design and construction. The consultant can peer review design and

construction documents and make recommendations for the stucco system and

installation during schematics, design development, construction drawings and

specifications preparation and make site visits to review the work in

progress to keep the architect and owner advised and assist in resolving

conflicts. While the architect assumes

all professional liabilities for this approach, it substantially reduces the

risks and satisfies a professional standard of care. Any time is an excellent opportunity to

engage the stucco consultant to review and update the office standard stucco

details and specifications used on all projects, to avoid repeating errors in

the future. Design/Build

stucco – another approach to stucco system delivery and quality control. Alternatively the architect can simply

depict the substrate conditions, required aesthetic and performance criteria

– just the desired objectives - and require the stucco to be a design/build

system designed and stamped by an experienced and licensed design

professional and constructed by an experienced and licensed stucco

contractor. On construction details

indicate the stucco cladding in outline only as an assembly, depict its

thickness for the assemblies and do not indicate a higher level of

detail. Specify that detailed

information will be provided in a required stucco submittal and shop drawings

package. A complete package of

submittals and shop drawings is prepared for the architects review and

approval. The cost to prepare stucco

shop drawings is less than the cost for the architect to design the stucco

system in a traditional approach, and to resolve problems occurring during or

after stucco installation. The stucco

cladding package may be a deferred submittal to the building department to

expedite the project if necessary.

Specify the performance and aesthetic criteria and leave the details

to those professionals that know stucco best, to design and install the

stucco cladding system for your building.

Minimized upfront costs are realized and the architect has limited

professional liability using this approach.

Design/Build performance and aesthetic criteria for each substrate

condition on the project includes: 1.

Substrate support condition(s) –

concrete, masonry, framing, sheathing, grillage 2.

WRB, wall drainage and flashing

requirements for openings and penetrations 3.

Fire-resistive assembly and

thermal efficiency requirements 4.

Traditional or proprietary

portland cement stucco cladding 5.

Opaque wall R or U-value and

sound attenuation requirements 6.

Locations and conditions of BMJS

subassemblies in the building structure 7.

Locations and conditions for wall

openings and penetrations 8.

Locations and interface

conditions with other Work 9.

Finish coat material, color, and

texture 10.

Etc. Stucco shop drawings directly

benefit stucco craftsmen: Stucco

shop drawings eliminate guesswork and unknowns – its planning the work, to make

working the plan go easier. Preparing

them requires pre-thinking the work in thorough detail, and indicating how

the stucco contractor intends to comply with the specified contract

requirements including workmanship standards.

The cost to prepare stucco shop drawings is much less than the cost to

resolve stucco problems occurring during or after stucco installation. Stucco shop drawings provide the required

level of detail to perform the work not fully depicted in the architect’s

contract documents. The drawings and

specifications are an important part of the construction contract and are

created to describe the architects intentions, but an architect’s standard of

care does not require that every condition be designed, detailed or

coordinated, only that the architect’s intent be ‘reasonably inferable’ which

may be interpreted differently by different stakeholders. Best to get this clarified before beginning

work, by means of architect approved shop drawings. Stucco

shop drawings document and communicate acceptable substrate requirements for

stucco. With the criteria communicated

to the other project team members, potential problems can be avoided. A stucco contractor should not be required

to install stucco over an unacceptable substrate, at least not without

additional coordination, time and compensation for repairs if corrections are

needed. Stucco shop drawings define

the criteria for an acceptable substrate for the general contractor to

coordinate with the concrete, framing and other project subcontractors before

it becomes an issue. Stucco

shop drawings indicate all surfaces requiring stucco. Occasionally, surfaces requiring stucco and

the required lath accessories and finishes are not depicted on the

architectural drawings. Examples are roof

penthouse and roof facing parapet walls, walls in recessed pockets, building

jogs ad recesses, or at distant planes of a section drawing, ceiling/soffit

conditions shown in section but not in plan and the wall return surfaces of

stucco clad arcades. Stucco shop

drawings indicate all stucco locations and coordinate terminations and lath

accessories as they turn corners and intersect other Work. Stucco

shop drawings clarify the different materials, finishes and textures required

and their locations. Stucco shop

drawings include a complete description of substrates, lath and lath

accessories materials, fasteners and other

required lath accessories and any special lath accessory finishes

required. Transitions and

intersections of lath accessory and the stucco assembly and its relationship

to Work by others depicted for coordination only, is clearly indicated. Stucco

shop drawings clarify finish coat materials and textures required and their

locations. Contemporary buildings are being

designed with multiple colors and textures and determining which combination

goes where, and coordinating their intersections, can be easily clarified on

stucco shop drawings. Stucco

shop drawings describe conditions conforming to or exceeding Minimum Stucco

Industry Standards and manufacturers requirements. Stucco shop drawings depict how the stucco

contractor will conform to the architects specified requirements and, where

necessary, identify proposed alternatives that can be discussed with the architect

using the RFI or substitution request processes. Stucco

shop drawings clarify and resolve conflicts before they escalate. Despite the architect’s best intentions,

contract drawings and specifications can omit or be silent about important

information, can conflict, can specify unavailable materials and can

reference obsolete practices or standards and other issues. Stucco shop drawings prepared by

professionals experienced with stucco proactively resolve potential issues. The

stucco industry is one of the few construction industries and one of the most

complex, that has not yet integrated shop drawings

into standard practice. ‘Submittals’

is the broad term that describes specified items that are in essence

communication tools that generally include product data, material samples,

manufacturer’s installation instructions, shop drawings and more. When specified, the contractor must submit

the required submittals to the architect as an initial contract required

process before the work begins, the primary purpose of which is to

communicate and coordinate the contractors understanding of the contract

requirements to the architect (and hence the owner) and the project

team. Submittals are a process that

assists in managing scopes of work and facilitates the review and approval of

the architect and owner of the work.

Common stucco submittals include product data, samples of finish coat

colors and textures and sometimes samples of lathing/lath accessory

materials, but these limited submittals are not adequate to address the needs

in today’s stucco delivery environment.

More information needs to be shared and coordinated amongst related

trades and more detail is needed to ensure the quality and performance

expectations of stucco specified is achieved. ·

Product data, manufacturer’s

installation instructions, MSDS for every material and component, only items

specified. When the submittal item

indicates options for materials, finishes, colors, dimensions, perforated/non-perforated

etc., clearly indicate which options will be provided. When providing submittals, be specific

about what is being submitted, do not submit the entire product catalog of a

manufacturer or reams of unrequested information. When a catalog page with multiple parts is

submitted, clearly indicate which items are being provided. ·

Stucco mortar mix design and

product installation instructions. ·

Installer experience

documentation ·

Product and Special Warranties ·

Stucco Shop Drawings ·

Stucco Mock-ups. Mock-ups can take one of several forms and

are purpose driven depending on the project’s needs. The scope of the mock-up must be

predetermined and clearly indicated on the construction documents and be of a

scope that is appropriate to a specific project’s needs. Mockups can simply be small sample panels

of the desired finish coat texture/color for review and owner selection if

that is all that is necessary to confirm.

Mockups can be full scale, free-standing partial wall systems to

verify the workmanship and joinery of various stucco subassemblies,

especially important with more complex joinery sub-assemblies or to

coordinate work amongst various trades.

Mock-ups can be the first installed work in place, which if acceptable,

can be incorporated into the completed work.

Mock-ups can be useful for air and water performance testing of

windows, the window/stucco interface, WRB penetrations and other conditions

such as lath fattener shiner repairs.

Mockups are best used to resolve coordination challenges, and for

particularly complex details, to verify workmanship and to serve as the

standard of acceptability for the balance of the work.

Stucco mock-up wall, with complex lath accessory

joinery and WRB conditions

Performance testing stucco

mock-up wall assembly What

are stucco shop drawings? Shop

drawings are in the submittal category are not a commonly specified stucco submittal but their use is

increasing. Stucco shop drawings

completely describe the detailed requirements and provisions for stucco

systems including requirements for staging areas, utilities, clear

identification of all locations and conditions receiving stucco on a building,

acceptable substrate and environmental requirements, required lath

accessories, jointing locations and configurations, mix design and

admixtures, installation methods, fastening requirements, required

accessories, protection of installed work, testing procedures, evaluation

criteria, relationships with adjacent work by others, etc. In other words, all detailed information

necessary to acceptably complete the stucco installation for a specific

project. Shop drawings express a level

of detail that is necessary to construct the stucco system, at a greater

level of detail than the general intent typical of an architect’s

2-dimensional drawings and specifications.

Shop drawings are assembly drawings and may include 3-dimensional

isometrics, a list of materials and quantities, as well as detailed

dimensional requirements and tolerances. Stucco

shop drawings provide complete and sufficient detail to clearly describe all

aspects of the stucco work to be provided for a specific project. Construction documents prepared by the

architect include drawings, details and specifications, but these are only

intended to generally convey the

architects design intent. They are not

sufficient to depict every aspect or condition in detail. Stucco shop drawings complement, and are in

addition to the other stucco submittals.

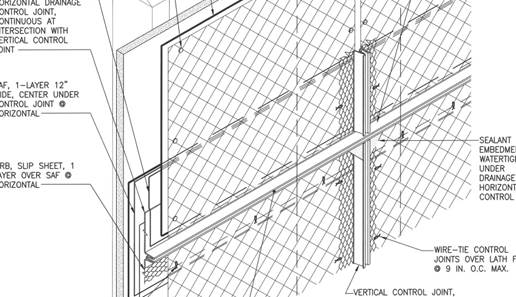

Excerpt portion of detail from

stucco shop drawings The

practice of merely copying and submitting the architects details and specifications

as shop drawings obviously does not contain the level of detail required of

stucco shop drawings. This practice

misses the major purpose of stucco shop drawings, which is to pre-identify

potential conditions not shown on the architects’ construction documents that

require resolution. The detailed

information stucco shop drawings may include: 1.

Site material, equipment storage,

staging and washout areas, lighting, utilities, enclosures etc. 2.

Substrate support acceptance

criteria requirements: Sheathing panel

gaps, joints and fastening, substrate characteristics for bonding (for

direct-applied stucco), planarity and alignment tolerances. Identifies methodologies and products to

correct unacceptable conditions 3.

Comprehensive building surface drawings

showing all locations for the stucco installation and lath accessories: Every

wall surface, ceiling and soffit, chimney, penthouse, and blind wall, etc. 4.

Comprehensive detailing and scope

of work required to install the stucco system and all specified components in

their required locations 5.

Details relationships with work

by others – windows, doors, louvers, electrical and piping penetrations, WRB,

flashings, sealant, SAF, painting and finishing, etc. 6.

Depicts each opening or

penetration, each surface mounted equipment, each outlet, louver, exhaust

duct, hose bib, fire sprinkler, recessed lighting, surface mounted electrical

disconnect etc., to coordinate stucco trims and detailing 7.

Details interior/exterior

building corners, perimeter edges of stucco 8.

Details lath accessory components

and installation - SMJS, PMJS, BMJS, lath accessories, weep screeds,

flashings, sealants, moldings and reveals: locations, terminations,

transitions, intersections, splices/laps, joinery, corner conditions,

fastening requirements, backing and back-up framing, lath accessory

installation and special finishes 9.

WRB inspection and repair

procedures/materials for spinner/shiner lath fasteners 10.

Moist curing procedures 11.

Finish coat texture and color 12.

Scaffold tieback removal repairs 13.

Detailed scheduling requirements

to complete the Work 14.

Mock-up scope and locations for

aesthetic or performance evaluations. 15.

Evaluation and testing criteria

and procedures to determine acceptability of stucco work from aesthetic and performance

viewpoints 16.

Potential caveats common to

stucco are identified, with evaluation tolerances and corrective repair

methods: Efflorescence, cracking,

color/texture issues etc. 17.

Owner maintenance

requirements/recommendations. 18.

And more… Stucco

shop drawings are a communication and coordination tool, benefitting the

project by sharing detailed information amongst the project team. Stucco

shop drawings benefit the owner by assuring the highest level of

communication amongst the project team, pre-identifying conflicts and

unanticipated conditions and working out early resolutions. The

stucco industry overall is not familiar with the purpose, level of detailing

or processing of shop drawings, or currently prepared to produce or manage them,

so there is a learning curve, and new skills will be necessary. Consultants are available to provide these

if the contractor needs assistance.

The shop drawing process is an excellent opportunity for stucco

craftsmen to impact a stucco installation and detailing by contributing their

specialized trade knowledge and skills to benefit a project by communicating

them to the design team, early in the project. Exterior

wall mock-ups including the stucco wall cladding are also commonly used on

larger scale projects. Mock-ups are an

initial installation of the stucco assembly that often includes most if not

all stucco conditions as well as other assemblies – framing, sheathing,

jointing, windows, doors, flashings, as well as approved colors and textures. Who

should prepare stucco submittals and shop drawings? Stucco

submittals and shop drawings can be prepared by any entity as determined and

coordinated by the general contractor, unless the architect specifies who

prepares them. Stucco

submittals and shop drawings prepared by the stucco contractor: Stucco contractors are not designers and

preparing stucco shop drawings does not necessarily make them designers,

unless they change the architects design. If the stucco contractor prepares

the submittals and shop drawings exactly following the contract document

requirements, there is no design liability to the stucco contractor. Stucco

submittals and shop drawings prepared by the general contractor: Where stucco submittals and shop drawings are

required contractually, the general contractor can contract to have the

entire package prepared separately, even before a stucco contractor is

selected. With a complete package of

approved stucco submittals and shop drawings, the most competitive bids can

be obtained, based on the same detailed scope of work that the submittal and

shop drawing documents define and convey.

This approach is especially effective for fast track and design-build

projects, where the entire exterior wall assembly can be a critical

design-build turn-key component to the projects’ advantage to achieve single

source responsibility, cost and scheduling efficiencies. |

|

A

traditional shop drawing and submittal preparation and review process can

benefit the project in general and stucco wall cladding systems in

particular, in innumerable ways. It is

long past due that complete shop drawings and complete submittals become a

standard part of the stucco industry process for stucco wall cladding

systems. |

|

Minimum Standard of Care:

Stucco shop drawings are not a requirement for satisfying the Minimum

Stucco Standard of Care for stucco, unless specified in construction

documents. Stucco

Best Practices: ·

The design authority should

specify that comprehensive stucco product and installation data submittals

and shop drawings be prepared and submitted to the architect for review and

approval. Specify qualifications of

preparer, whether or not a licensed design professional stamp is required

(especially if a design/build process is utilized), and any specific shop

drawing required information, such as soldered flashings provided by others

be shown on the stucco shop drawings for coordination purposes. Shop drawings should include all the design

items indicated on this website, and additional details and information as

required to completely install the stucco wall

cladding system to comply with project requirements. ·

The construction authority should

prepare and submit complete submittals and shop drawings for stucco

work. Indicate requirements for

substrate, locations and installation requirements for stucco assembly

components, lath accessories and intersections, attachments, interfaces with

adjacent assemblies and components. ·

The design authority should

graphically depict and specify a comprehensive stucco mock-up assembly to be

constructed by the contracted stucco craftsman that will perform the stucco

work to the building, to coordinate the stucco assembly installation and lath

accessories, and to evaluate stucco aesthetic characteristics. Include every stucco condition that occurs

on the building on the mock-up – substrates, WRB, drainage flashings and screeds,

lath accessory splices, intersections and terminations, finish materials,

textures and colors, and interfaces between the stucco and adjacent materials

and construction. Include the accepted

repair process for fastener shiners, and scaffold tieback penetrations, and

water test examples of these repairs for water resistivity for quality

assurance. Reconstruct the mock-up if

not approved, correcting errors as many times as necessary for approval, when

the mock-up then serves as a benchmark reference for the actual stucco work

to the building. |

|

Consultation with licensed and experienced stucco professionals

is recommended for stucco-related endeavors.

No liability is accepted for any reason or circumstance, specifically

including personal or professional negligence, consequential damages or third

party claims, based on any legal theory, from the use, misuse or reliance

upon information presented or in any way connected with StuccoMetrics.com. |

Home Page Contact

Me Disclaimer