StuccoMetrics R

Jeff Bowlsby CCS, CCCA

Exterior Wall and Stucco Consultant

Licensed

California Architect

Stucco Material Properties

|

Webpage Quicklinks Stucco Thermal Contraction/Expansion

Movement Stucco Thermal

Contraction/Expansion Stucco Shrinkage

Movement and Thermal Movement Combined |

||||||||||||||||||||||||||||||||||||||||

|

Material

properties for stucco and stucco-related materials are indicated Stucco shrinkage and thermal movements are

presented that are not typically available from other resources without

significant research. Shrinkage and

thermal movements are inherent material properties of portland-cement based

plaster and stucco that are not well grasped in the industry. Shrinkage and thermal movements if

accommodated can be managed. Shrinkage

and thermal movements if not accommodated can cause perimeter stucco panel

edge gaps and stucco cracks that may be unsightly, may allow bulk water

intrusion into the stucco cladding assembly and should be addressed with any

competent stucco cladding assembly design. Visit the StuccoMetrics Reference Archives

webpage for cited references and further information. |

||||||||||||||||||||||||||||||||||||||||

|

In 1921, the US Bureau of Standards, published Shrinkage of Portland Cement Mortars,

and its Importance in Stucco Construction, which

documented an extensive battery of testing on stucco and its components

because it recognized the potential and importance of stucco to the US

economy. One series of the testing

evaluated 200 prepared specimens of portland cement stucco mortar with precision

equipment to evaluate the shrinkage characteristics of various stucco mortar

mix designs.

1921 US Bureau of Standards stucco shrinkage testing apparatus The shrinkage characteristics of

the stucco mortar specimens tested included materials and mix designs

comparable to today’s stucco. The

conclusion was that a common 1:4 (cement:sand)

portland cement-based stucco mortar experienced shrinkage of up to

0.14%. The total shrinkage occurred at

approximately 256 days after placement.

At the time when the stucco finish coat is typically installed

approximately 70% of the total shrinkage had occurred, and after 28 days

approximately 75% of the total shrinkage had occurred.

The total shrinkage dimensional

value after 256 days was approximated 168 mils (0.168 in.) of length change

over 10 feet of stucco. At the time,

stucco shrinkage was considered to be of minor concern related to cracking,

and it was concluded that with adequate moist curing and control of

absorption by the substrate, that stucco shrinkage and shrinkage-related

cracking could be minimized.

1921

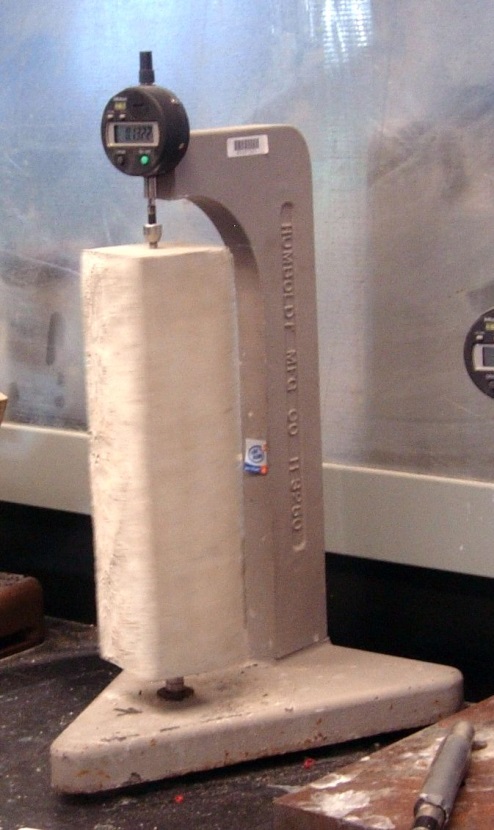

US Bureau of Standards stucco shrinkage test results In 1940 the test method was further developed for measuring

portland cement mortar shrinkage, and became the test standard we know today

as ASTM C157 Standard Test Method for

Length Change of Hardened-Hydraulic Cement Mortar and Concrete. ASTM C157 is the current industry testing

standard for this purpose and it is an effective method to isolate and

evaluate the shrinkage characteristic of an isolated portland cement-based

mortar specimen. The laboratory test

method creates small specimens of portland cement stucco mortar in a

temperature and humidity controlled environment to isolate shrinkage

behavior, cures them by immersion in a lime bath and precisely measures their

length change at intervals typically up to 28 days after the portland cement

hydration process is initiated.

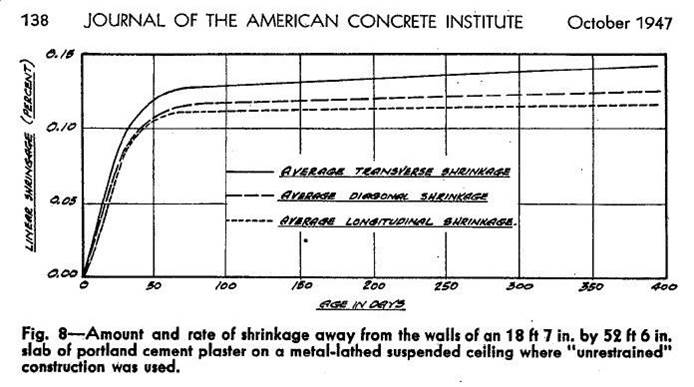

ASTM C157 Shrinkage testing apparatus with specimen One of several documented actual stucco installations that

experienced stucco shrinkage was a major stucco installation at the Grand

Coulee Dam construction project in 1947 as documented in Crack Control in Portland Cement

Plaster Panels, Journal of the American Concrete Institute. Stucco ceilings on suspended metal lath

experienced significant and unacceptable cracking where the ceiling lath was

continued onto and attached to the adjacent concrete walls, the standard lath

installation practice at the time.

Extensive investigation and testing was performed by the Bureau of

Reclamation to determine the cause of the cracks and to develop a

remedy. A primary conclusion was that

a stucco assembly including the lath at ceilings on suspended grillage, needs

to be isolated (discontinuous and unrestrained) from the adjacent perimeter

concrete walls to allow for cement-based plaster shrinkage movement to occur,

and to minimize stucco cracking resulting from shrinkage movement. The shrinkage dimensional movement was

field measured as 3/4 in. over a ceiling surface that was 52 ft in length,

which equated to 0.120%

field-measured shrinkage movement, or 144 mils (0.144 in.) over 10 feet. The

study also evaluated the traditional portland cement industry milestone of 28

days as an indicator of final characteristics, but at 28 days only ~50% of

the total shrinkage had occurred.

Finish coats are often already installed by 28 days and may be subject

to additional base coat shrinkage before the base coats are fully cured. Most of the shrinkage had occurred after

approximately 75 days, so according to this study a more useful milestone for

determining total stucco shrinkage is 75 days or longer. Shrinkage occurring after 75 days is measureable

and should be considered, but it is incidental and can be accommodated by

applying a safety factor to the 75 day shrinkage amount.

1947 Grand Coulee Dam -

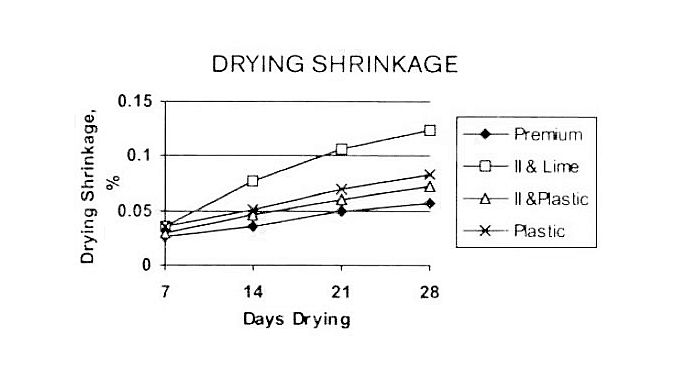

Stucco shrinkage rate and time duration A few contemporary stucco product manufacturers publish ASTM

C157 shrinkage data for their products, but it is not a common practice. Below is one graph of data from one

manufacturer indicating approximately 0.12% shrinkage for generic Type II

portland cement and lime stucco mixture and approaches half that amount using

other portland cement-based stucco product variations. Note that the shrinkage indicated here is

only through 28 days, no indication of total shrinkage is given, which is

critical information.

2008 Manufacturer-published stucco shrinkage data In a 2010 private study, Performance Impact of Various Fiber

Additions in ASTM C926 Plaster Basecoat, was

performed to evaluate the effects of fiber additives regarding stucco

shrinkage. The laboratory testing

performed was extensive and included a range of commercially available fiber

additive materials useful for stucco, towards minimizing stucco

cracking. The testing revealed a range

of effects on the performance characteristics of stucco with fiber additives,

but overall the contributory effects of fiber additives regarding stucco

shrinkage movement was found to be negligible. Fiber additives are understood in the

industry to more uniformly distribute stucco shrinkage stresses within the

stucco membrane and to reduce the visibility of cracking in general, but have

negligible effect on actual stucco shrinkage. Stucco Thermal Contraction/Expansion Movement As

is the common behavior of nearly all materials, in service ambient cyclical

temperature changes cause installed and cured stucco to expand and

contract. Linear thermal expansion

coefficient values used to determine the expansion and contraction

dimensional values for portland cement-based stucco are published by a few

different sources, summarized in Cement Plaster Metrics: Quantifying Stucco Shrinkage and Other

Movements; Crack Acceptability Criteria for Evaluating Stucco published by RCI. The

corresponding range of dimensional movement is calculated to vary over a

range from approximately 48-84 mils (0.048-0.084 in.) over 10 lineal feet, based

on a change in ambient temperature of 100oF which can occur after the stucco is cured and in service. |

||||||||||||||||||||||||||||||||||||||||

|

Stucco cracking, especially at wall opening

corners, has been a known stucco performance behavior and concern since the

use of stucco on framed buildings began over a century ago. Stucco shrinkage movement rates and dimensional

values have been known for nearly a century and the basic relationship

between stucco shrinkage and stucco cracking has been understood since at

least the late 1940’s. Stucco

shrinkage and thermal movement data is available from a few different sources

that are generally corroborative. Stucco shrinkage movement accounts for

the majority (approximately 60-80%) of the total combined stucco dimensional

movement attributed to stucco shrinkage movement and thermal movement. Stucco thermal movement after curing, while

in service, is a comparatively smaller movement, but is still significant. Stucco shrinkage is not complete when

finish coats are typically applied, and continues for nearly a year. Many stucco product manufacturers do

not currently publish ASTM C157 shrinkage data for their portland

cement-based stucco products. |

||||||||||||||||||||||||||||||||||||||||

|

All portland cement-based plaster, and

stucco, experience shrinkage movement and thermal expansion and contraction

movement. Stucco cracks and perimeter

gaps are the manifestation of these characteristics. Marketing hype for stucco products such as ‘Our stucco has low

shrinkage’…or… ‘use our enhanced stucco admixture for minimum shrinkage

cracking’, are conceptual, anecdotal and effectively meaningless without

factually supportive and comparative data.

How much is ‘low’ shrinkage…compared to what? What shrinkage dimensional value actually

occurs with a given stucco material so that stucco shrinkage movement can be

accommodated in stucco design and installation? Stucco products available on the market

today that affect stucco shrinkage movement include not only portland

cement-based products, but also admixtures and aggregates. Stucco shrinkage movement gets the lion’s share of the attention,

in a negative way, for virtually all stucco cracking that occurs, yet do we

really understand actual stucco shrinkage characteristics and behaviors, and

how to accommodate them in stucco systems, assemblies and subassemblies

towards minimizing cracking? Buildings

move in winds and seismic events, beams and floor slabs deflect under dead

and live loadings – each of these physical movement conditions can be

rationally observed, evaluated, the behaviors are predictable, and solutions

can be derived and implemented to accommodate them. How about for stucco shrinkage

movement? What is the dimensional

value of stucco shrinkage movement occurring after placement? If we understand stucco shrinkage

characteristics and behaviors, we should be able to do something about it. Stucco shrinkage movement occurs during the initial curing process

and is irreversible – no amount of thermal expansion movement while in

service after curing compensates for stucco shrinkage movement. Many factors impact the specific rate,

magnitude and visible effects of stucco shrinkage of a particular stucco

system. Factors such as portland

cement type and content, aggregate characteristics and contamination,

admixtures, cement:aggregate ratio, cement:water ratio, workmanship, finish coat

characteristics and other factors are essential considerations to understand

before we can fully assess and address the effects and impacts of stucco

shrinkage movement of a particular stucco system. The simple fact is that stucco shrinks

during initial curing, an irreversible, inherent natural process, and the

force of greatest magnitude to which stucco wall cladding must contend. Cured stucco contracts during cold ambient

temperatures, effectively shrinking even more. Cured stucco expands during hot ambient

temperatures, but the expansion does not compensate to make up for the

shrinkage it initially experiences.

Without provisions that address and minimize these movements, stucco

responds by cracking. These movements

must be accommodated in some way by using one or more of various methods in

combination - stucco mortar mix design and curing provisions, admixtures and

additives, panelization with shrinkage movement joint subassemblies, crack

isolation base coats and finish coatings that perform well enough to cover

and conceal the cracks. ASTM C157 is a useful

laboratory test protocol for evaluating shrinkage rates of stucco mortar

specimens. ASTM C157 provides important benchmark information but other

factors need to be considered to effectively understand and interpret the

testing protocol results. From

observations of previous stucco shrinkage testing and documented actual

stucco installations, we know that stucco continues to shrink for nearly a

year after placement and that at 28 days, the standard ASTM C157 test time

period, approximately only 75% of the total stucco shrinkage has

occurred. Stucco will be in service

much longer than 28 days on most buildings, so a 28 day value is only useful

if compared to the total shrinkage that will occur over time, and if the

future shrinkage behavior relationship can be predicted. The lime bath curing of stucco mortar

specimens in a temperature and humidity controlled environment does not

accurately emulate field-installed stucco curing conditions. The test method

documentation indicates that field cast specimens may experience up to twice

the shrinkage movement as lab cured specimens, an important factor that

should be considered. Laboratory testing of mortar-only specimens is useful information

but the shrinkage performance of an actual field installed stucco system is

impacted by additional factors that demand consideration. Lath embedded into stucco may restrain

stucco shrinkage movement, but ASTM C157 does not account for the effects of

embedded lath. Variables in lath type

related performance and lath fastening conditions as they relate to stucco

shrinkage may impact the effective shrinkage rates of a given stucco system,

but ASTM C157 does not account for the variable effects of embedded lath

types. Admixtures that purport to

effect stucco shrinkage can also be evaluated with the ASTM C157 testing

protocol. The contributory effects of

these additional factors are not quantified at this time and require

additional testing and evaluation to discern. Aggregate contamination by clays and organic matter can be a

contributory source effecting stucco shrinkage. Aggregates are often locally sourced and of

variable qualities and purity, especially for site mixed generic,

non-proprietary stucco mortar. ASTM

D2419 Standard Test Method for Sand Equivalent Value of Soils and Fine

Aggregate is the standard test protocol useful to determine aggregate

contamination levels. Mineral aggregate

itself does not shrink, but residual clays and organic matter contamination

in the aggregate can be a stucco shrinkage concern. No simple

field test currently exists to evaluate a stucco mixture during or

immediately before stucco installation, for potential stucco shrinkage

movement. Stucco product manufacturers

in general do not publish shrinkage testing or thermal movement data for

their products. This lack of information

makes it challenging to design or install stucco to accommodate shrinkage and

thermal movements with certainty. Moist curing, portland cement content, aggregate characteristics,

fiber additives, admixtures, SMJS subassemblies, workmanship, finish coat

characteristics and other factors are essential considerations to address the

effects and impacts of stucco shrinkage movement on a particular stucco

system. When the

stucco system installation is complete, stucco shrinkage movement is not yet

complete and continues for nearly a year.

As the shrinkage process continues, combined with thermal movements

while in service, cracking can continue to develop. The characteristics and performance of the

stucco finish coat is the final mechanism for accommodating cracking over the

long term, after everything else is in place.

Finish coat texture, color, elastic properties, and thickness are

important considerations for minimizing the visibility of stucco cracking

during its service life, over the test of time. Shrinkage

reducing admixtures (SRA) have been on the market and useful in structural

concrete for bridges and paving for many years. Common SRA’s include chemical solutions or

fly ash. SRA can easily be adapted to

portland cement-based plaster and they are not expensive. SRA should be considered in the design of

stucco mixtures for minimizing stucco shrinkage, but this approach has not

migrated into stucco practice and requires more research and testing before

it can be applied to stucco. Stucco

Thermal Contraction/Expansion Second only as a stucco crack-causing

villain to stucco shrinkage, what stucco thermal movement dimensional value

occurs while in service? How much

stucco cladding thermal movement occurs from a hot summer day to a cold winter

night? Stucco system thermal contraction and expansion movements are

behavioral reactions to thermal temperature cycling after curing, while

in-service. Many factors affect the

actual dimensional magnitude of contraction/expansion movements on a particular

stucco system. With stucco, whatever thermal expansion

amount that may occur cannot regain the initial shrinkage amount experienced

during curing. Stucco Shrinkage Movement and Thermal

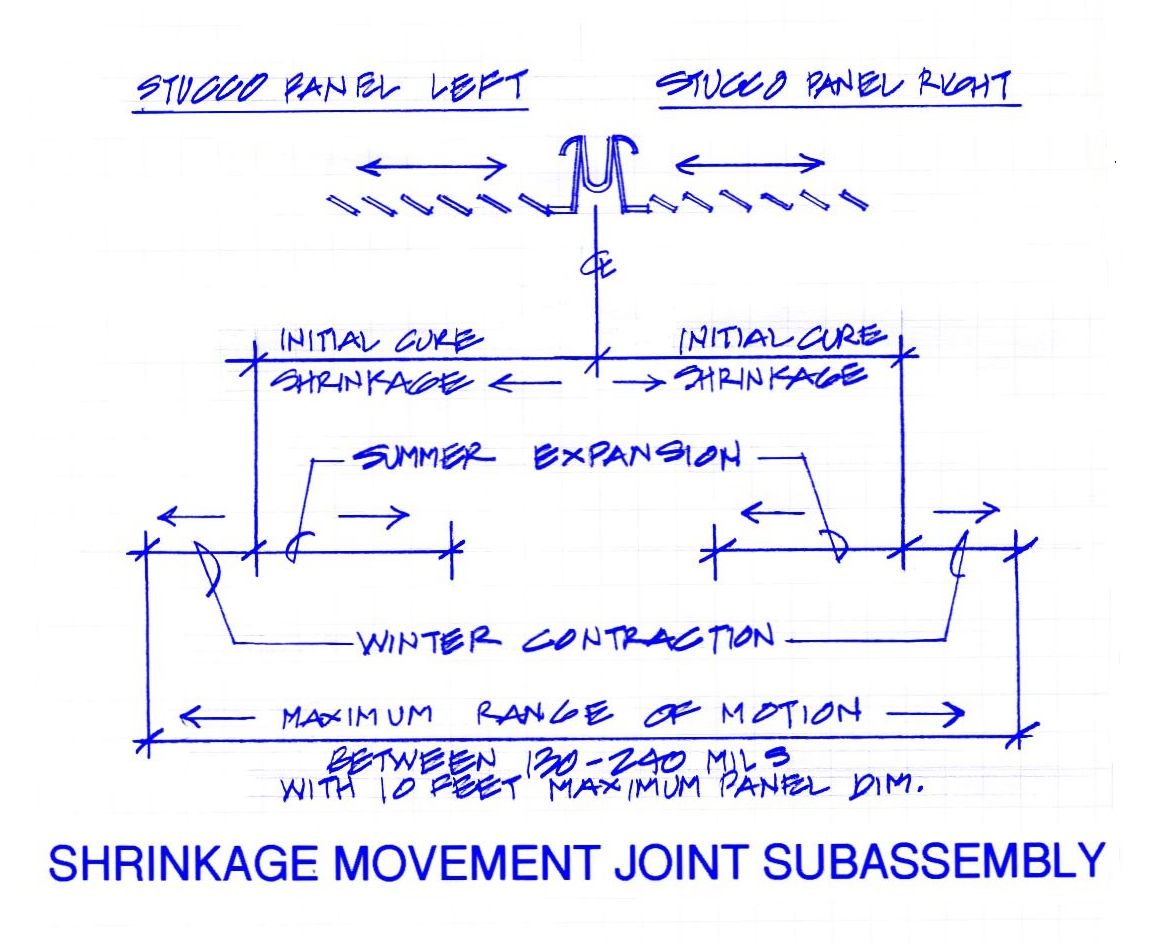

Movement Combined The following diagram indicates an

idealized, generalized stucco behavior pattern, based on a series of

assumptions of typical conditions, for the combined behavior of stucco

shrinkage and thermal movement over a 10 foot length of stucco. Note that it illustrates: ·

An

initial portland cement shrinkage dimension that cannot be regained,

resulting in a stucco panel edge gap ·

Once

cured and while in service, in higher temperatures, the cured stucco expands,

reducing the stucco panel edge gap ·

Once

cured and while in service, in lower temperatures, the cured stucco

contracts, enlarging the stucco panel edge gap. ·

Of

the total movement, shrinkage accounts for ~80%, thermal contraction ~20%

For design purposes, stucco shrinkage

and thermal contraction/expansion movements combined are understood to be in

the general range of approximately 130-240 mils per 10 lineal feet of stucco

length as reported by RCI in

Cement Plaster Metrics: Quantifying

Stucco Shrinkage and Other Movements; Crack Acceptability Criteria for

Evaluating Stucco. |

||||||||||||||||||||||||||||||||||||||||

|

The stucco design and construction communities

require complete performance data regarding stucco shrinkage and thermal

movement behaviors for the products it specifies and installs, to better

accommodate stucco shrinkage movement and thermal movement characteristics,

and to more effectively minimize stucco cracking. An

ASTM C157 test value at 28 days suggests a stucco shrinkage rate, but does not

represent the total stucco shrinkage that occurs after approximately a year,

which is the more useful information.

Lime bath specimen curing is not an accurate representation of actual

field installations. More valuable stucco shrinkage performance information would

be obtained by using field cured specimens. Stucco

product manufacturers are encouraged to perform and publish ASTM C157 and

D2419 shrinkage and thermal movement related data for their stucco mortar and

related products. Consideration should

be given to using field-cured specimens, that include the various available

embedded lath materials and admixtures and any other factors that may

contribute to stucco shrinkage movement. Consideration should be given to

extending the testing protocol to at least a 12 month long duration to

evaluate actual stucco shrinkage and thermal movement characteristics of

stucco materials and systems to be useful in the design and installation of

stucco, and to minimize stucco cracking. SRA products should be further

evaluated and considered for use in stucco to reduce stucco shrinkage

movement and minimize stucco cracking. |

||||||||||||||||||||||||||||||||||||||||

|

Stucco shrinkage (during

curing), design value: ·

100-200

mils (0.10-0.20 in.) per 10 lineal feet Stucco shrinkage and thermal movement

combined, design value: ·

130-240

mils (0.13-0.24 in.) per 10 lineal feet Coefficients of Lineal Thermal Expansion

(CLE) (comparison):

Stucco

Best Practice: Manufacturers

of portland cement-based stucco materials are encouraged to perform and

publish applicable ASTM C157 and D2419 engineering technical data for their

materials. The data should include characteristics for stucco shrinkage and

thermal movement as used in standard stucco mixtures, to provide meaningful

and useful information for the effective design and installation of stucco

wall cladding systems, and to minimize stucco cracking. Also provide information regarding the

following additional factors to evaluate their effects: ·

Use field cured stucco specimens ·

Test all stucco materials that have an impact on stucco shrinkage, such

as portland cement-based materials, admixtures and aggregates, and in their

various common combinations ·

Use stucco specimens with embedded laths to

understand their composite behavior ·

Extend the shrinkage test protocol to a 12 month

time duration and provide a shrinkage vs time informational graph |

||||||||||||||||||||||||||||||||||||||||

|

Consultation

with licensed and experienced stucco professionals is recommended for

stucco-related endeavors. No liability

is accepted for any reason or circumstance, specifically including personal

or professional negligence, consequential damages or third party claims,

based on any legal theory, from the use, misuse or reliance upon information

presented or in any way connected with StuccoMetrics.com. |

||||||||||||||||||||||||||||||||||||||||

Home Page Contact Me Disclaimer