|

StuccoMetrics® |

Jeff Bowlsby CCS, CCCA

Exterior Wall and Stucco Consultant

Licensed

California Architect

Stucco Lath Accessory Identification

|

Executive Summary What is an

#X-2 lath accessory? A #25 lath

accessory? A #64N lath accessory? When a stucco craftsman refers to these lath

accessories or a specifier specifies a lath

accessory using these designations, what exactly is being referred to? Is a #7 lath accessory a defined industry

standard lath accessory with an engineering drawing and an ASTM-type

specification - the same from manufacturer to manufacturer in every

respect? How are lath accessory

variations designated such as longer flanges, ground dimensions,

perforations, material or finish options? Where is the master list of stucco lath

accessory numbers or designations for reference? This webpage explores and answers these

questions. Visit the StuccoMetrics Reference Archives

webpage for cited references and further information. |

|

Context Xx |

|

Observations Xx |

|

Discussion The term ‘stucco lath accessory’ is

widely used but not defined in the industry.

For simplicity, I use the categories of lath, lath fasteners and lath

accessory for clarity. ASTM stucco

standards refer to stucco lath accessory as ‘accessories’ which is a very

broad term used to describe a wide range of lath accessory components with

different flange types, functions, installation requirements and more, and

these distinctions are not always clearly presented in the ASTM standards. The term ‘stucco lath accessory’ is a

better term for the purposes of this discussion and is used here because it

is a more appropriate term when used so broadly and it avoids confusion and

misinterpretations without getting into the finer points of each accessory and

the stated requirements within the ASTM standards for accessories. Certain

sectors of the construction industry, generally by geographic regions or

within trades, have become accustomed to using terminology that is not well-defined

or universally agreed upon throughout the industry. Terms like ‘Boston ridge’, ‘French drain’,

‘hog valley’ and the like can be confusing or may have multiple

meanings. Stucco too has its own

language in the form of using certain lath accessory numbers that have come

to mean certain things to certain people in the stucco industry. The problem is that the lath accessory

number or name referenced by one person may mean something different to

someone else because they may have different reference points, experiences or

preferences. As an industry, we should

seek to eliminate any potential misunderstandings by using a common language

and this pertains to how stucco lath accessory items are referenced. Stucco

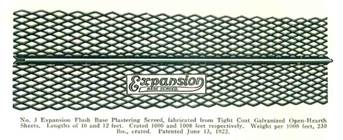

lath accessories developed over time based on stucco needs and were

introduced to the market as early as the 1920’s by companies such as the

Milwaukee Corrugating Co. (which became known as Milcor),

and each company had their own catalog of stucco lath accessory products they

brought to market. The first stucco

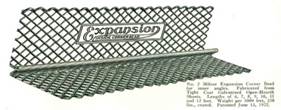

lath accessory widely available was the corner bead such as produced by Milcor, so that lath accessory item became known as the

#1 in their catalog and ultimately became a standard way of referencing this

lath accessory component in the trade.

As the various manufacturers catalogs grew, more lath accessories were

added and more numbers. Each

manufacturer used their own method of naming and numbering their products,

sometimes using the common industry descriptors of well-established products

such as ‘#1”, and sometimes using a different numbering or naming

system. So a #X

lath accessory by one manufacturer, could be different than a #X by another

manufacturer, and in fact that is exactly what has happened. A generic master coordinated stucco

lath accessory designation list universal to all manufacturers, with

engineering drawings or ASTM-style product standard for stucco lath

accessories does not exist. Lath

accessory designations as used today and in the past can be a number, a name,

a number and name, or an alpha-numeric designation and vary widely between

manufacturers with only limited consistency.

Stucco trade traditions for the general descriptions of certain lath

accessories by number or name have passed down through the generations, but

this practice should be used with great caution because of the limited

consistency throughout the industry.

Consideration should be given to abandon this practice and replacing

it with a universal lath accessory designation system. On a jobsite, craftsman casually referring

to lath accessories by number is common trade practice and may not cause any

heartburn, but for an Architect or specifier to use

and rely on that same casual nomenclature in details or specifications is

imprecise and does not communicate exact requirements. Stucco lath accessory number

designations are utilized in different ways by different manufacturers. Most commonly a manufacturer assigns a lath

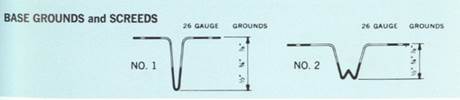

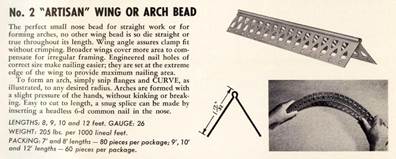

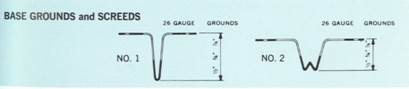

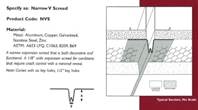

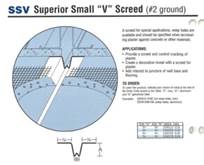

accessory number to a basic sectional profile configuration (e.g. Nos. 1, 7,

66), loosely based on tradition. Other

times, a manufacturer will use a lath accessory number to designate size

(e.g. Nos. 38, 50, 75, 100 Zinc Control Joint by Clark Western, or the Nos.

120, 140 by Superior). Making

things more interesting, manufacturer’s today modify those base numbers with

prefixes and suffixes to further describe and distinguish their product from

competitors. An X-__ can be expanded

flange, where an __–N can be a nailing flange, etc. Stucco lath accessories may and often

do serve multiple functions. Similar

but different stucco lath accessories may have the same number designation

but have different installation requirements or function differently. For example, a casing bead lath accessory

terminates the stucco mortar, and its ground functions as stucco thickness

gauge and provides a surface to seal to an adjacent window or door. If the casing bead lath accessory has an

XSM flange, it is appropriate and performs best to install it over lath,

wire-tied to the lath edge, allowing the stucco mortar to key the lath

accessory with the lath, so that when the stucco shrinks the casing bead goes

with it preventing a gap between the stucco and casing bead lath

accessory. If the casing bead has a

solid flange, it is required to install it under the lath, fastened to the

framing. When the stucco shrinks a

small gap may occur between the casing bead lath accessory and the edge of

stucco with solid flange lath accessories fastened to the framing. Lath accessories with differences in flange

types – solid or XSM – should be installed differently. XSM flanged lath accessories if screwed or

nailed in place over a WRB, can damage the WRB and cause water intrusion, and

so are best wire tied over lath. Solid

flanged lath accessories are best placed directly over the WRB and fastened

to framing. A major point of this website is that

the common practice of designating lath accessories by a traditional number

or name has diluted the understanding in the industry of the distinction

between simply identifying a lath accessory component and the functional and

performance characteristics of the assembly the lath accessory component

helps create. In other words, by

itself a corner bead lath accessory is not an arris

assembly, it is one component in a configuration of several components,

including the framing, WRB, lath, lath fasteners, corner bead lath accessory,

lath accessory fasteners, stucco mortar that fills and surrounds the corner

bead lath accessory, and the stucco finish coat, that each contribute to

making an arris assembly. Similarly, all by themselves, a control

joint lath accessory is not a control joint assembly and a weep screed lath

accessory is not a drainage assembly, without considering the other related

components in the assembly. It

is more clear and correct when referencing stucco lath accessory items to

reference them using a complete manufacturer name and catalog number. To be complete and accurate, a lath accessory specification requires

the lath accessory manufacturer name and complete lath accessory description

including material, critical dimensions and variations specified that are

available by that manufacturer to minimize errors when designing, specifying,

ordering, purchasing and installing stucco lath accessories. This website avoids the designation of

stucco lath accessories by number, name or alpha-numeric designation to avoid

any misunderstanding. A new replacement standard lath

accessory referencing convention is needed that is universal among lath

accessory manufacturers that will more accurately describe lath accessories

and reference associated installation requirements and reduce

misunderstandings. Best Practice: The current practice of

referencing lath accessories only by number, name or alpha numeric designation

is flawed and obsolete and should be abandoned because no standard universal

comprehensive lath accessory designation system exists. Further Research: This

would help to promote communication, prevent inconsistencies and errors in

the industry. Consider categorizing

assemblies and lath accessories suggesting the function of the assembly, as a

possible preliminary designation using the 2-4 letter acronym lath accessory

categories I have used in the index. References ·

Cemco catalog, 2009 ·

Clark Western catalog, 2006 ·

Milcor Manual, 1924 ·

Milcor Partition Handbook, 1940 ·

Milcor catalog, 1960 ·

Stockton catalog, 2004, 2005 ·

Superior

catalog, 1977, 2001, 2004 ·

PennMetal catalog, 1959 ·

Western Metal Lath catalog, 2005 |

|

Conclusions Xx |

|

Suggestions Xx |

|

Consultation with licensed and experienced stucco professionals

is recommended for stucco-related endeavors.

No liability is accepted for any reason or circumstance, specifically including

personal or professional negligence, consequential damages or third party

claims, based on any legal theory, from the use, misuse or reliance upon

information presented or in any way connected with StuccoMetrics.com. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Consultation with licensed and experienced stucco professionals is

recommended for stucco-related endeavors.

No liability is accepted for any reason or circumstance, specifically

including personal or professional negligence and consequential damages,

based on any legal theory, from the use, misuse or reliance upon information

presented or in any way connected with StuccoMetrics.com. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Home Page Contact Me Disclaimer