|

StuccoMetrics® |

Jeff Bowlsby CCS, CCCA

Exterior Wall and Stucco Consultant

Licensed

California Architect

Stucco Cracks

|

Webpage Quicklinks A Study of Stucco Crack

Typologies Wall Opening Cracks WOC 01 Wall opening reentrant corner crack,

omitted SMJS WOC 02 Wall opening reentrant corner crack,

omitted SMJS at corner, crack migrates to nearby penetration WOC 03 Wall opening reentrant corner crack

migrates to adjacent dead end EATS WOC 04 Wall opening reentrant corner crack

connecting two adjacent reentrant corners at non-square/rectangular (L-shape)

stucco panel configuration, omitted SMJS WOC 05 Wall opening reentrant corner crack, with

SMJS WOC 06 Wall opening reentrant corner radial

cracks emanating from small wall opening Soffit

Cracks SOFC 01 - Soffit reentrant

corner crack, with SMJS SOFC 02 - Soffit cracking at

ceiling soffit, parallel to rib lath span direction Field

of Wall Cracks FOWC 01 - Field of Wall

parallel vertical cracking aligning with stud spacings FOWC 02 - Field of Wall

cracking perpendicular to length of narrow roof parapet wall panel, omitted

SMJS FOWC 03 - Field of Wall

horizontal parallel linear cracking at wall surfaces FOWC 04 - Penetration crack

– lighting fixtures, guardrails, pipes, etc. FOWC 05 – Field of Wall

cracking at stucco thickness variations – lath line wires at open stud

framing FOWC 06 – Field of Wall

cracking at stucco thickness variations related to wrinkly building paper Planar

Transition Cracks PTC 01 - 3-plane intersection

(innie), reentrant corner of primary wall plane,

omitted SMJS PTC 02 - 3-plane intersection

(outie), reentrant corner of primary wall plane, onto adjacent recessed sill

corner, omitted SMJS Lath

Accessory Cracks LAC 01 - Perpendicular crack

at SMJS lath accessory splice along stucco panel edge LAC 02 - D-crack emanating

from SMJS splice, at acute angle pie-corner panel geometry. LAC 03 - D-crack emanating

from single horizontal SMJS splice near panel corner. LAC 04 - D-crack emanating from

and connecting two SMJS splices near panel corner. LAC 05 - D-crack at stucco

panel corner, at arris condition LAC 06 - Dead end SMJS

termination crack LAC 07 - Lath accessory

profile transition crack, omitted SMJS LAC 08 - Parallel crack at arris corner LAC 09 - Parallel gaps along

pointed ground lath accessory Building

Movement Cracks BMC 01 - Building movement

substrate support movement condition, omitted BMJS BMC 02 - Building movement

change in substrate condition, omitted BMJS Stucco

Crack Minimization Strategies |

|

A

study of stucco crack typologies, this webpage concentrates on the object and

characteristics of the stucco crack itself. Visible

stucco crack phenomena are readily observable conditions. Most people find stucco cracks

objectionable based on visual aesthetics to one degree or another, and it is

possible to reasonably minimize their occurrence with care in stucco cladding

system design and craftsmanship. They

may represent normal stucco conditions and behavioral characteristics, they

may be the result of insufficient stucco design or construction, or they may

be the result of exposure to extreme service conditions. Stucco cracks may or may not be the

manifestation of concealed defects which may become discernable once the

mechanisms that caused them are understood. Visit the StuccoMetrics Reference Archives

webpage for cited references and further information. |

|

Stucco cracks can be attributed to a number of various potential

conditions and combinations of conditions.

It is well understood that some of the primary causes of stucco cracks

include conditions and characteristics related to the following broad

categories, this is not a comprehensive list: ·

Stucco

substrate support and movements ·

Stucco

lath and lath accessories materials and installation ·

Stucco

mix design and components ·

Stucco system,

assembly, subassembly and component design ·

Stucco

thickness variations ·

Stucco

curing ·

Stucco

shrinkage and thermal movements ·

Stucco

finish assemblies ·

Stucco

in-service environment conditions As one of the traditional and primary approaches to stucco crack

minimization, BMJS, SMJS and PMJS can be effective at minimizing stucco

cracking. This webpage concentrates on

stucco movement joints as a primary crack minimizing method, but these are

only one of several methods and considerations. Shrinkage Movement Joint Subassemblies (SMJS) developed initially from

the Perimeter Movement Joint Subassembly (PMJS), so a complete understanding

of the principles and context presented on the PMJS webpage is fundamental to

a foundational understanding of these subassemblies along with the additional

information presented on this webpage. Other stucco crack minimization methods concern themselves with the other

bulleted topics above, which may be addressed elsewhere on this website now

or in the future. |

|

Stucco cracks are generally a manifestation

of unmitigated stucco stresses. Many factors

contribute and combine to cause stresses resulting in stucco cracks. Careful observation and evaluation of

stucco crack patterns reveals a common repetitive typology of cracks and

vocabulary of consistent crack characteristics and conditions. The following examples of stucco crack

patterns are an indication of generally occurring, often predictable and

therefore potentially avoidable stucco crack patterns. This webpage resource may be useful as a

general guide only, it should not be considered as comprehensive or absolute,

and does not purport to suggest absolute or guaranteed mitigation for

avoiding all stucco cracks. Stucco movement joint lath accessories and

SMJS, PMJS and BMJS were developed to minimize stucco cracking caused by

initial stucco shrinkage, thermal movements, and building substrate support

movements. All stucco movement joint

subassemblies require discontinuous lath and other requirements to function

correctly and to minimize stucco cracking. A Study of Stucco

Crack Typologies: Unmitigated stress

concentration conditions manifesting as stucco cracking, with commentary on

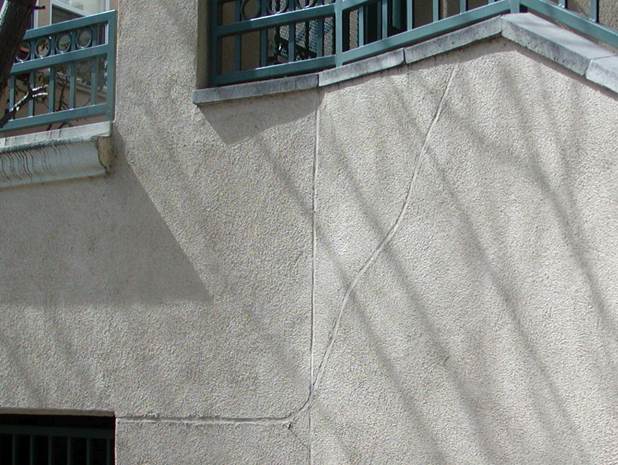

Minimum Stucco Standards of Care and Stucco Best Practices. Wall Opening Cracks Wall Opening Crack WOC 01:

Wall opening reentrant corner crack, omitted SMJS. The most common

stucco crack condition. ·

Stucco Best

Practice: Avoid reentrant corners at stucco

panels. Locate SMJS at wall

opening reentrant corners.

Wall Opening Crack WOC 02:

Wall opening reentrant corner crack, omitted SMJS

at corner, crack migrates to nearby penetration. ·

Stucco Best

Practice: Locate SMJS at reentrant wall opening corners, provide lath patch reinforcement at wall

penetrations.

Wall Opening Crack WOC 03: Wall opening

reentrant corner crack migrates to adjacent dead end EATS ·

Stucco Best

Practice: Locate SMJS at reentrant wall opening

corner. Avoid dead end EATS and lath

accessories.

Wall

Opening Crack WOC 04: Wall opening reentrant corner crack connecting two adjacent reentrant

corners at non-square/rectangular (L-shape) stucco panel configuration,

omitted SMJS. ·

Stucco Best

Practice: Avoid non-square, non-rectangular

stucco panel configurations (L-shape, C-shape, donut shape) to avoid

reentrant wall opening corners. Locate

SMJS between adjacent reentrant wall opening corners to create square or

rectangular stucco panel configurations.

Wall

Opening Crack WOC 05: Wall opening reentrant corner crack, with SMJS. ·

Minimum Stucco

Standard of Care: Assure correct SMJS installation with

discontinuous lath for maximum SMJS movement.

Wall

Opening Crack WOC 06: Wall opening reentrant corner radial cracks emanating from small wall

opening ·

Stucco Best

Practice: Either locate SMJS at each reentrant corner,

or specify lath reinforcement patch.

Soffit

Cracks Soffit Crack SOFC 01: Soffit

reentrant corner crack, with SMJS.

Even small reentrant corner conditions may propagate cracking. ·

Stucco Best

Practice: Avoid reentrant corner condition at

stucco panels. Locate SMJS at

reentrant corners and avoid non-square, non-rectangular stucco panel

configurations.

Soffit Crack SOFC 02: Soffit cracking at ceiling soffit, parallel to rib lath span direction. ·

Stucco Best Practice:

Avoid using rib lath at ceilings/soffits due to its inherent capability

of creating stucco thickness variations which often result in linear,

parallel cracking. Require

ceiling/soffit joists at 16 in OC maximum spacing, use 3.4 expanded metal lath, V-Groove.

Field

of Wall Cracks Field of Wall Crack FOWC 01: Field of

Wall parallel vertical cracking aligning with stud spacings. ·

Stucco Best Practice:

Avoid stucco on open stud framing without sheathing to avoid stucco

thickness variations that often result in cracking.

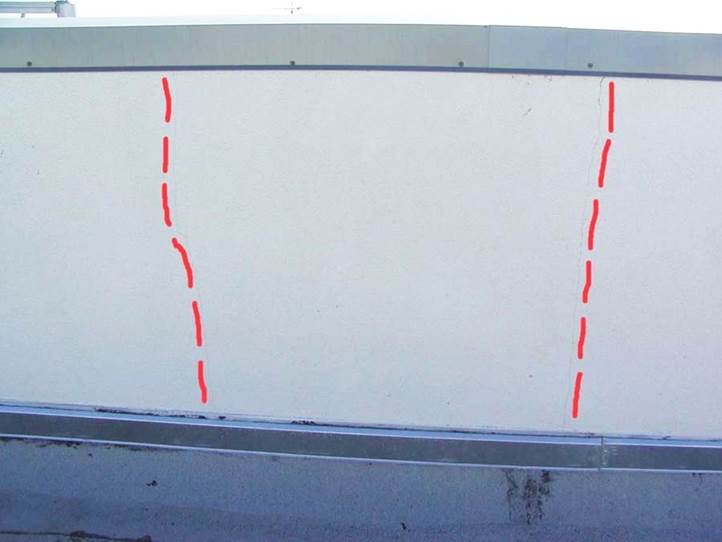

Field of Wall Crack FOWC 02:

Field of Wall cracking perpendicular to length of narrow

stucco clad wall panels such as parapet walls, and omitted SMJS. Panels between cracking occur in small

square to rectangular proportions. ·

Stucco Best

Practice: Locate SMJS to create stucco panel

areas of 1:1.5 geometry maximum

Field of Wall Crack FOWC 03:

Field of Wall horizontal parallel linear cracking

at wall surfaces. This may be a workmanship issue related to ungapped sheathing panels, or

paperbacked lath with integral line wires on open stud framing (omitted

sheathing) or other condition. ·

Minimum Stucco

Standard of Care: Provide 1/8 in. gaps at wood-based

sheathing panel edges. ·

Stucco Best Practice:

Avoid stucco cladding on open stud framing without sheathing and use

of paperbacked lath with integral line wires.

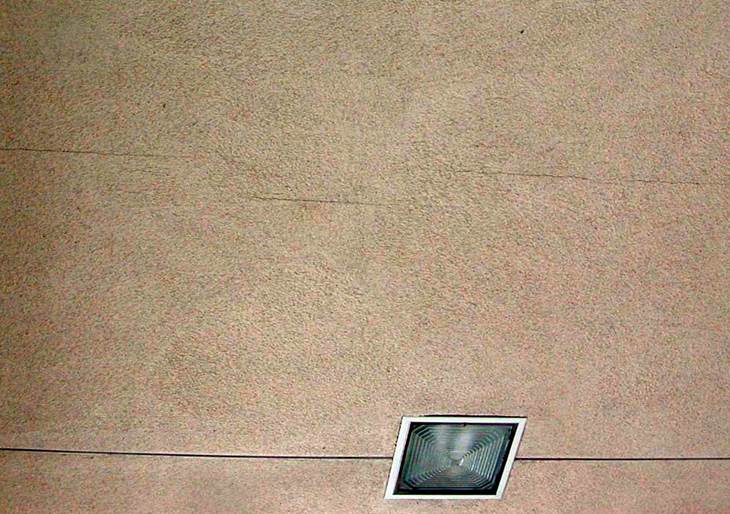

Field of Wall Crack FOWC 04: Penetration crack – lighting fixtures, guardrails, pipes, etc.

Field

of Wall Crack FOWC 04A: Penetration crack – lighting fixtures, guardrails, pipes, etc. ·

Stucco Best

Practice: At penetrations such as lighting

fixtures, pipes/conduits, dryer vents provide lath patch on the diagonal,

over the primary wall lath for additional reinforcement against localized

cracking. Provide isolation collar

(flashing) with sealant filled gap at penetrations to accommodate localized

shrinkage movement and differential movement with penetrating item.

Field of Wall Crack FOWC 05: Field of Wall cracking at

stucco thickness variations – lath line wires at open stud framing. ·

Stucco Best

Practice: Avoid open stud framing and use of

paper backed lath with line wires.

Field of Wall Crack FOWC 06: Field of Wall cracking at

stucco thickness variations related to wrinkly building paper ·

Minimum Stucco

Standard of Care: Provide SMJS correctly installed with

discontinuous lath, small panel sizes and other methods of minimizing stucco

cracking.

Planar

Transition Cracks Planar

Transition Crack PTC 01: 3-plane intersection (outie), reentrant corner of primary wall plane,

omitted SMJS. ·

Stucco Best

Practice: Locate SMJS on primary wall at

reentrant corner of 3-plane intersection and provide Double-V Internal Corner

SMJS at adjacent interior corners.

Planar Transition Crack PTC 02: 3-plane

intersection (innie), reentrant corner of primary

wall plane, onto adjacent recessed sill corner, omitted SMJS. This crack may also be related to a

sheathing panel edge incorrectly located to align with wall opening corner. ·

Minimum Stucco

Standard of Care: Assure sheathing panel joints are offset

from corner (4 in minimum per ASTM C1280), and if of wood-based panel

sheathing, the panel edges are gapped 1/8 in. ·

Stucco Best

Practice: Provide SMJS aligning with wall

opening reentrant corner on primary wall plane and provide Double-V Internal

Corner SMJS at adjacent interior corner.

Lath

Accessory Cracks Lath Accessory Crack LAC 01:

Perpendicular crack at SMJS

lath accessory component splice (butt splice) along stucco panel edge. ·

Stucco Best Practice:

Avoid locating lath accessory splices along stucco panel edges,

terminate only at intersections with other lath accessories.

Lath Accessory Crack LAC 02: D-crack

emanating from SMJS splice, at acute angle pie-corner panel geometry. ·

Stucco Best

Practice: Avoid pie-corner stucco panel

geometry. Avoid lath accessory butt

splices along panel edges, terminate lath accessories only at intersections

with other lath accessories.

Lath Accessory Crack LAC 03: D-crack

emanating from single horizontal SMJS splice near panel corner. ·

Stucco Best

Practice: Avoid butt splices of lath accessories

along panel edges, locate lath accessory splices only at intersections with

other lath accessories, not along panel edges.

Lath Accessory Crack LAC 04:

D-crack emanating from and connecting two SMJS

splices (butt splices) near panel corner. ·

Stucco Best

Practice: Avoid lath accessory butt splices

along panel edges, locate lath accessory splices only at intersections

with other lath accessories, not along stucco panel edges.

Lath Accessory Crack LAC 05:

D-crack at stucco panel corner, at arris

condition. ·

Minimum Stucco

Standard of Care: Assure correct SMJS installation with

discontinuous lath for maximum SMJS movement. ·

Stucco Best

Practice: Locate SMJS to create panel areas of

1:1.5 geometry maximum

Lath Accessory Crack LAC 06: Dead end SMJS termination crack ·

Stucco Best Practice:

Avoid dead end SMJS, terminate SMJS at intersections with other lath

accessories.

Lath Accessory Crack LAC 07: Lath accessory profile

transition crack, omitted SMJS. ·

Stucco Best

Practice: Locate SMJS at lath

accessory profile

changes, do not transition lath accessories along stucco panel edges.

Lath Accessory Crack LAC 08: Parallel crack at arris

corner. ·

Minimum Stucco

Standard of Care: Assure lath continues around corner 1 stud

bay minimum and that external corner reinforcement is packed solid with

stucco.

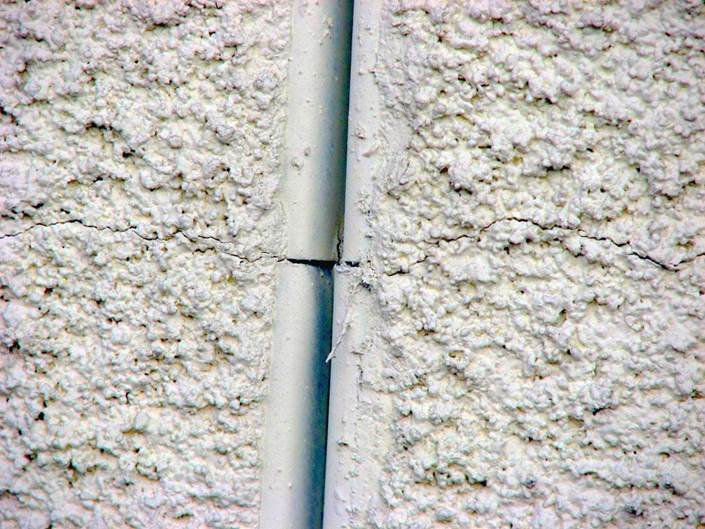

Lath

Accessory Crack LAC 09: Parallel gaps along pointed ground lath

accessory (SMJS lath accessory). A gap

can form at each side of a pointed screed as stucco shrinkage and thermal

movement occurs.

Lath Accessory

Crack LAC 09A: Parallel

gaps along pointed ground lath accessory (SMJS lath accessory). A gap can form at each side of a pointed

screed as stucco shrinkage and thermal movement occurs. ·

Stucco Best Practice:

Avoid pointed ground (Single-V or Double-V) lath accessories; provide

Single-J or Double-J lath accessories with capture flange.

Building

Movement Cracks Building Movement Crack BMC 01:

Building movement substrate support movement

condition, omitted BMJS. ·

Minimum Stucco

Standard of Care: Locate BMJS at substrate support

movement locations.

Building Movement Crack BMC 02:

Building movement change in substrate condition,

omitted BMJS. ·

Minimum Stucco

Standard of Care: Locate BMJS at change in substrate material.

|

|

Like death and taxes, everyone knows and

acknowledges that stucco cracks. It’s

frequently the only conclusion – sometimes framed as the answer to a mystery

when discussing why stucco cracks.

“Why do stucco cracks occur?

Because stucco cracks!”, when it really should be the response of last

resort, and when nothing else can explain the crack phenomena. The postulation here

is that as a generality, cracks occur for a rational reason or combination of reasons; we just need

to understand the reasons better and do what is appropriate to minimize the

likelihood they will occur, or otherwise accept the results. If we can get to the place where we better

understand the conditions and characteristics or mechanisms that cause stucco

cracks, we may be able to get to the place where we can greatly diminish

their occurrence and frequency. Stucco cracking at reentrant wall opening

corners has been the single-most pervasive stucco crack condition and

typology since portland cement-based plaster was first used as an exterior

wall cladding on buildings over a century ago, including through today. The combination of reentrant wall opening

corners such as at windows, doors and similar wall opening conditions, and

the stucco cracks that propagate from them are a

fundamental and significant issue

for the design authority and construction authority of exterior stucco wall

cladding system to be cognizant of and to address. Stucco cracks at reentrant wall opening

corners can generally be minimized and potentially avoided with attention to

detail in both the design and construction of stucco wall cladding systems. Discussions of stucco cracking must consider the

characteristics of the entire stucco system – the substrate support, WRB,

lath and fasteners, lath accessories, base coats, all materials and

workmanship, the finish assembly, texture and service and lighting

conditions. Stucco finish assemblies

and textures have an important function in the stucco system for crack

mitigation, where higher performance finishes and more articulated textures

may help mitigate cracking better than brittle, low performance smooth

surface finishes. No studies have been

performed or published information available by any entity as yet, to

quantify what the mitigating effects of higher performance finishes or more

articulated textures are, so as we discuss cracking generically, we can only

presume the discussion to be in the context of minimum quality stucco systems

– such as those that include cement finish coats, with integral color or

painted, and a flat, planar, sand float texture. Most rationale people agree that stucco cracking is an eyesore, but do

circumstances exist where a stucco crack might be considered by some to be

marginally acceptable? A research

paper I authored and which was published in 2010 by RCI, Cement Plaster

Metrics: Quantifying

Stucco Shrinkage and Other Movements; Crack Acceptability Criteria for

Evaluating Stucco, explored

this question. The conclusion was that

the answer has two parts – a rational component and a subjective component. As a practical matter, a stucco crack should not be

acceptable if it has a role related to water intrusion that causes visible or

concealed damage. Some cracks

penetrate the full thickness of the stucco membrane and can function as

direct water pathways leading to the concealed WRB or substrate support. Not all cracks are water pathways that

result in concealed damage. Stucco

wall cladding systems are typically constructed in multiple layers of

portland cement-based plaster, where outer coats can conceal cracks at

underlying coats. Proprietary stucco

offered by certain manufacturers may consist of only a single coat of

portland cement-based plaster.

Three-coat stucco typically has scratch, brown and finish

coats by design as a characteristic of that system, which is a matter of good

practice, and by its multiple layers adds redundancy. Stucco Best Practices include additional

layers such as a fabric-reinforced lamina basecoat or thicker finish coats

which exceed minimum requirements. An

important functional reason for this is that a crack forming in an underlying

coat is often covered and may not translate into or through subsequent coats

to the stucco surface. Cracks in the

scratch coat can be concealed by the brown coat, and brown coat cracks can be

concealed by the finish coat, etc. A

stucco cladding system with a greater number of plaster coats will likely

have less visible cracking at the finish coat surface than a stucco cladding

system with fewer coats. Is a crack

that one cannot see in a concealed layer, a problem either functionally or aesthetically? The answer should be obvious to a

reasonable person. ·

Acceptable

stucco cracking: The stucco cladding

system correctly complies with all required crack minimizing provisions so

that cracking within the stucco cladding system could be qualified as

acceptable. BMJS, PMJS and SMJS are

correctly installed and located, portland cement-based plaster is correctly

proportioned, installed and cured, substrate support conditions are

correct…in other words no condition is incorrect. This circumstance is the condition where

the phrase ‘acceptable stucco cracking’ is appropriate. Minimum Stucco Industry Standards are just

that – minimums, not Stucco Best Practices.

Some degree of ‘less than perfect’ should be acceptable when minimum

standards are followed. Beyond that, stucco crack acceptability can and should be evaluated

based on a range of visible aesthetic priorities and subjective criteria of

the beholder. It is not likely that

any two people will agree on the acceptability of any single crack, so

ultimately a neutral person with authority just needs to make a

well-considered determination. The

crack location, crack width, crack depth, crack visual density (visible

cracking within a specific area), stucco finish color, texture and material,

lighting conditions when observed – all these and more effect the

acceptability of stucco cracking to individual persons. That being said, based on my 2010 paper Crack

Acceptability Criteria for Evaluating Stucco, the current general

consensus in the industry, all sourced considered, is that a crack not

exceeding 30-mils in width and narrower, may be

conditionally acceptable in certain circumstances. Cracks narrower than 30-mils

wide in a smooth texture finish may not be acceptable to some. A 30-mil wide crack and narrower, may not

be very noticeable under certain conditions, and may be repairable with high

performance finish coatings if the aesthetic of the coating is acceptable,

which may not always be the case. A

crack located at the building entry at eye level may be objectionable to

everyone, whereas the same crack on the third floor rear wall of a building

may not be as much of a concern aesthetically because it is difficult to

visually access. A series of adjacent

cracks less than 30-mils wide may be objectionable

on the basis of visual density. When can stucco cracking reasonably be categorized as excessive stucco cracking? Some will suggest that any stucco crack is

an excessive crack. At the other

extreme others will pretty much shrug off any type or amount of cracking as a

normal condition… “all stucco cracks” they say as if

that cliché is a hall pass to trivialize any issues and justify the

acceptability of any and all cracking.

If any single crack or group of cracks does not have a role related to

water intrusion, then the condition is probably not a functional concern in

terms of keeping the building water tight.

Excessive stucco cracking

then becomes an aesthetic condition only.

A few resources have attempted to define excessive stucco cracking in

largely subjective terms. They

suggest a certain number of lineal feet of cracking of a certain maximum

width per square foot of stucco or words to the effect that excessive

cracking means visually objectionable – but those criteria are not easy to

define where everyone will agree.

Those approaches are non-starters because they are difficult to

quantify and subjective at best. A method for defining excessive cracking that can be considered is to

use a rational evaluation process which is non-subjective. One condition for stucco cracks to be

considered as acceptable is the condition when stucco cracking occurs, in

spite of the fact that all required measures to minimize cracking are

correctly implemented. Excessive

cracking would be just the opposite.

Excessive cracking is stucco cracking that develops when all required

or specified measures to minimize cracking are not implemented or not

correctly implemented. ‘Required’

means required by building code requirements which reference Minimum Stucco

Industry Standards, or as specified requirements in contract documents. This approach allows a variability in

evaluating “acceptable” and “excessive” cracking conditions, based on the

qualities and characteristics of the specified stucco wall cladding system,

which is appropriate and determined based on the qualities and

characteristics of the specific requirements of a given stucco wall cladding

system. It is generally reasonable to

expect that a minimum quality stucco wall cladding system will perform to a

lower standard (i.e. crack more) than a higher quality stucco wall cladding

system (i.e crack less). ·

Excessive

stucco cracking: The stucco

application is not fully compliant with all required crack minimizing

provisions, so the stucco cladding system or any portion of it could be

justifiably categorized as excessively cracked. Any number of issues could describe this condition

– oversized stucco panel areas, incorrectly located or installed BMJS, PMJS

or SMJS, incomplete curing, over fastening the lath, omission of specified

fibers, incorrect substrate conditions, etc. Stucco

Crack Minimization Strategies As a baseline, essential methods and

approaches to minimizing cracks are described and required in the building

code and Minimum Stucco Industry Standards.

These include a number of items many take for granted such as correct

substrate preparation, 2 layers WRB, the specification and correct use of materials

with certain characteristics – cement, aggregate, and water, effective

workmanship, effective moist curing, etc.

Minimum Stucco Industry Standards also require the effective use of

stucco movement joint assemblies and subassemblies correctly located and

configured, with no exclusions.

Excessive cracking can occur if one or more of these potential

maladies is overlooked or omitted. The essential purpose for BMJS, PMJS and SMJS

is to minimize the potential for stucco cracking by minimizing the transference

of movements into and through the stucco cladding system, and releasing the

induced stresses that manifest as stucco cracking at the stucco surface. That can be a tall order and complicating matters, BMJS, PMJS and SMJS are imperfect subassemblies. BMJS isolate the stucco wall cladding system

from substrate support movements, and are located as the buildings substrate

support requires. A BMJS minimizes

stucco cracking caused by building substrate support movement by physically

isolating the edges of separate, adjacent building substrate support sections

and their associated stucco wall cladding panels from each other. The lath and substrate support are

discontinuous at BMJS. Visit the BMJS

subassembly webpage for more information. PMJS isolate the stucco wall cladding system

from substrate support movements, and are located at

perimeter conditions such as where columns penetrate through stucco soffits

or where substrate support materials or conditions change. A PMJS minimizes stucco cracking caused by perimeter building substrate

support movement by physically isolating the edges of separate, adjacent

perimeter building substrate support sections and their associated stucco

wall cladding panels from each other.

The lath and substrate support are discontinuous at PMJS. Visit the PMJS subassembly webpage for more

information. SMJS

isolate adjacent stucco panels from each other, providing a location for

shrinkage and thermal forces to accumulate, to minimize the possibility of

stucco cracking. While the substrate

support is continuous through the SMJS because the SMJS is only concerned

with stucco shrinkage and thermal movements and not substrate support

movements, the lath is

discontinuous at SMJS. Visit

the SMJS subassembly webpage for more information. Other crack minimization strategies include

enhancing the system, adding redundancies, higher quality materials and

workmanship. Fiber additives and

polymer admixtures in basecoats minimize cracking. More rigorous moist curing minimizes cracking. Continuous fabric-reinforced lamina

basecoats, closer spacing and strategic location of movement joints minimize

cracking as do more flexible finish coats and more articulated textures. The positive effects of these and other

approaches to minimizing stucco cracking are recognized, but their exact

level of enhancement is not known or quantified. To achieve the highest quality stucco with

the fewest cracks, consider including as many of these enhanced approaches

for minimizing cracking. Should crack repairs be contemplated,

effective repair method options are limited. The important characteristics of

a specific crack require evaluation including whether the crack is static or

dynamic, its causation, relationship to water leakage, location, width,

length, relationship to adjacent cracks and building components, and other

factors must all be considered before deciding on the need for and

requirements to repair the crack. Some cracks that are not otherwise

aesthetically objectionable may best be left unrepaired to minimize the

aesthetic impacts of repairs. Painting

alone may be a sufficient repair for the smallest of static cracks, if

painting is appropriate for the specific stucco assembly. Other cracks will be determined to require

more elaborate repairs. One proven

effective solution overlays a complete, new continuous fabric reinforced base

coat and finish coat over the entire affected panel(s), between panel joints,

corners and perimeters. Absent a new finish coat, attempts to make

localized spot repairs may not be aesthetically acceptable as a result of

challenges in matching or blending with the existing finish coat color or

texture. These methods include

combinations of painting, routing out the crack and installing sealant, rubbing

in patching compound, and spot repairs.

Crack Repair: Crack

routed, sealant installed, then painted

Crack Repair: Crack not

routed, patching compound rubbed into crack, then painted

Crack Repair:

Pigmented cement finish, spot patched |

|

The stucco crack typologies illustrated

depict stress concentration locations and conditions that have manifested as stucco

cracking, which serve to inform us of typical conditions where BMJS, PMJS and

SMJS should be located, and how they should be configured for optimum

performance. The purpose of this

stucco crack typology study is to begin to catalog consistent and recurring

stucco crack phenomena, in hopes of understanding stucco cracks better and

ultimately to eliminate them from the stucco dialogue. We

as stucco designers, craftsman and regulators should use the available

materials and methods and do whatever it takes to avoid and mitigate

excessive stucco cracking by using precaution in stucco cladding design and

construction. The default phrase “all

stucco cracks” as used to justify every crack is clearly overused, unreasonable

and not always rationally justifiable.

As an industry we have the knowledge, technology and capabilities to

minimize the likelihood of most stucco cracks. Let us be encouraged to provide robustly

designed and constructed exterior stucco wall cladding systems with

conditions conducive to avoiding cracking.

Every condition and component of the stucco wall system from its

substrate support condition to its finish coat and texture must be evaluated

and selected to minimize and avoid stucco cracks. The

term ‘acceptable stucco cracking’ can be mostly rationalized but has

components that are subjective, whereas the term ‘excessive stucco cracking’

can be fully-based on a rational evaluation. Localized

crack repairs present challenges and the most effective repairs apply a new finish

coat system over an entire panel surface. |

|

Minimum

Stucco Standard of Care: ·

Comply

with the ASTM C926 requirement for the design authority to determine and

depict BMJS, PMJS and SMJS type, location, depth,

and method of installation in the project contract documents. Stucco

Best Practices: ·

Follow

suggestions for BMJS, PMJS and SMJS indicated on their respective StuccoMetrics.com

webpages. ·

Carefully

review and consider the relationships of common stucco cracking patterns and

typology to building substrate support, stucco shrinkage and thermal movement

stress concentrations. Recognize the

conditions and locations that cause stucco cracking to occur, and take

precautions to avoid or minimize stucco cracking. ·

Provide

BMJS, PMJS and SMJS in strategic, stress concentration locations,

that function to minimize stress concentrations within the stucco

cladding s, and that define stucco panel areas and proportions more

conservatively than current Minimum Stucco Industry Standards require. ·

Recognize that by definition, BMJS, PMJS, drainage screeds, and casing

beads, create one or more stucco panel area edges, terminations if you will,

because lath does not continue through, but terminates at them. These are literally, functionally and

therefore effectively one-half of an SMJS because shrinkage and thermal

movement can occur at them. ·

At small dimension penetrations such as

piping, electrical boxes, provide an isolation flashing collar with an

annular gap filled with sealant over backer rod to accommodate localized

movements at the penetration isolated from the stucco cladding, and an

additional lath reinforcement patch over the primary lath. This lath reinforcement patch should be a

large aperture lath such as welded wire lath to allow excellent plaster

embedment with the primary lath, and be installed on the diagonal, extending

beyond the penetration by 6 inches minimum, and be wire tied to the primary

lath layer to avoid lath fasteners that would otherwise miss framing. ·

Implement some or all stucco crack

minimizing methods, materials and proprietary enhancements to minimize stucco

cracking. Stucco

Best Practices: ·

Avoid pointed ground V or Double-V lath

accessories to avoid the parallel gap that may allow water

intrusion behind the stucco, unless they are horizontal drainage screeds that

are intended to allow drainage from the gap that will occur between the edge

of the screed and the stucco. Minimum

Stucco Standards of Care: ·

Comply

with ASTM C1063 requirements for BMJS, PMJS and SMJS installation

requirements |

|

Consultation with licensed and experienced stucco professionals

is recommended for stucco-related endeavors.

No liability is accepted for any reason or circumstance, specifically

including personal or professional negligence, consequential damages or third

party claims, based on any legal theory, from the use, misuse or reliance

upon information presented or in any way connected with StuccoMetrics.com. |

Home Page Contact Me Disclaimer