|

StuccoMetrics® |

Jeff Bowlsby CCS, CCCA

Exterior Wall and Stucco Consultant

Licensed

California Architect

Stucco Buckets

|

Webpage Quicklinks |

||||||||||||

|

“Stucco buckets” are anathema to stucco

and should be avoided. Visit the StuccoMetrics Reference Archives

webpage for cited references and further information. |

||||||||||||

|

The

term “stucco bucket" is a term that was coined in the construction

forensics community, when the effects of weather-exposed, ground facing,

outer soffit corner conditions caused cracked, stained stucco cladding and

deteriorated, concealed horizontal framing. Patent research: Not all soffit drainage screed flashing lath

accessory components and subassemblies are patented and not all patented BMJS lath accessory components were produced or are currently available. Select BMJS lath accessory components and subassemblies are discussed.

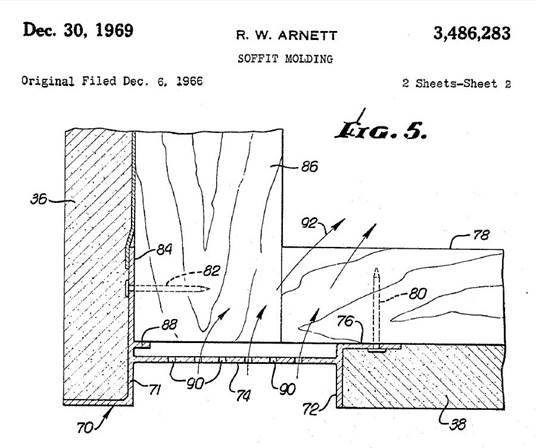

The

1969 Arnett soffit drainage screed flashing lath accessory component and

subassembly was the first to recognize the need and provide a solution for

soffit corner drainage, and the first significant use of extruded aluminum

lath accessories in the stucco industry.

Several variations of this component are available in ventilated and

non-ventilated configurations and this component has remained essentially unchanged

since it was introduced to the market.

1969

Arnett Soffit Drainage Screed flashing lath

accessory component and subassembly (Ventilated version depicted) As

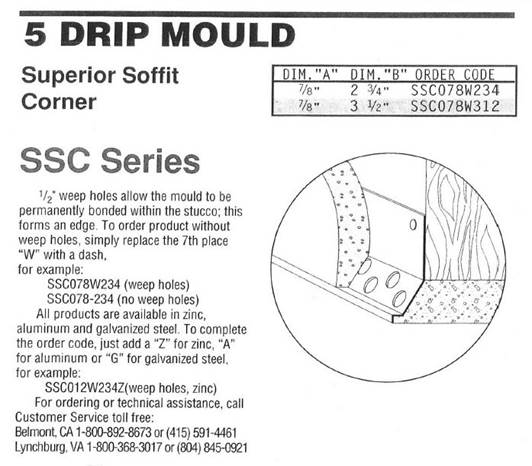

early as 1972, the Superior Metal Trim Products Co. offered a soffit drainage

screed flashing lath accessory component and subassembly as the “Drip Mould #5 – For soffits and foundations – FHA

Approved”. Superior is no longer in

business, and has been acquired by Stockton Products.

1972

Superior Co. #5 Drip Mould Drainage Screed flashing lath accessory component

and subassembly (Image from

the 1991 catalog) In

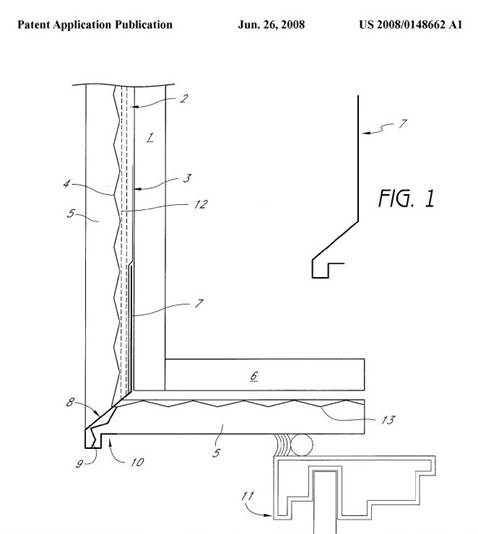

2008 a patent was issued to Don Pilz for a soffit

drainage screed flashing lath accessory component and subassembly. This component features a longer attachment

flange as a flashing component with the WRB, a sloped drainage surface, an

extended drip edge at the corner, and brown coat screed at the soffit

surface.

2008

Pilz Soffit Weep Corner Drainage Screed flashing lath accessory component

and subassembly |

||||||||||||

|

A

stucco bucket is a configuration of exterior stucco wall cladding located at

the bottom of a vertical stucco wall, where the stucco and its WRB are

continuous and wrap and return onto an adjacent stucco soffit surface. Water that does not drain out from behind

the cladding can be trapped between the continuous WRB and the framed

substrate support causing decay and deterioration of the substrate

support. The condition can occur at

locations such as exposed beams that support roofs, projecting bays and balconies,

stair landings, recessed window and door heads, and soffit corners above

recessed building entries. Soffit

surfaces defined as weather-exposed surfaces (WES) are the most vulnerable.

Stucco Bucket

01: Stucco bucket under projecting weather-exposed wood framed soffit at

bay window.

Stucco Bucket

02: Stucco bucket at weather-exposed metal framed soffit at wall recess. Stucco

buckets occurring at weather-exposed locations may trap water within the stucco

cladding system and may damage concealed framing and the exposed cladding.

Stucco Bucket

03: Stucco bucket at weather-exposed dropped perimeter beam. Parallel crack and staining at

horizontal soffit surface. Technically,

stucco bucket configurations can exist at weather-protected locations, but

are generally not of concern at protected locations because the condition is

not weather-exposed. Stucco

buckets often occur below long beams supporting shallow roof overhangs or

balcony edges, or at exterior weather-exposed stair well landing edge

beams. In these applications the

stucco cladding panel area geometry easily exceeds Minimum Stucco Industry

Standards, which may cause cracks that potentially contribute to water

intrusion related concealed water-related damages.

Images

courtesy of Christine Diosdado PE Simpson Gumpertz & Heger, Inc. Stucco Bucket

04: Stucco bucket at weather-exposed dropped perimeter beam below elevated

walkway. Parallel crack on

vertical wall and staining on exposed stucco surfaces. |

||||||||||||

|

Stucco

buckets earned their description from the water containment effect of the

stucco cladding system as if it were a bucket, where it wraps from a vertical

wall onto an adjacent horizontal soffit surface, directing water into the

soffit assembly. A stucco bucket

configuration with continuous stucco and WRB,

provides no mechanism for draining water contained within the vertical stucco

wall assembly, to get out. The

contained water may be held against framing members where it can cause

concealed damage whether the framing is wood or metal. The

building code defines weather-exposed surfaces (WES), which are effectively

all exterior building surfaces that are not weather-protected, in specific

geometrical and dimensional configurations, by roofs, overhangs and perimeter

soffit beams. WES can include the

vertical wall surface above the soffit corner, the horizontal soffit surface

contiguous with the soffit corner at dropped beams, stair landing edges,

recessed window and door opening heads, soffit surfaces at recessed building

entryways and similar conditions. At

longer spanning beam soffit edges, water may collect and cause damage

proximate to the center of the beam span resulting from normal beam

deflection.

Stucco Bucket

05: Stucco bucket at weather-exposed dropped perimeter beam, the bullnose

corner is a give-away. Parallel

crack on horizontal soffit beam surface during water testing. Note water nozzle in background and water

droplets at beam soffit crack. Certain

stucco bucket configurations can be exacerbated by adjacent weather-exposed

construction that accumulates and directs water towards the stucco bucket,

such as tube steel exterior stair support tubes or stringer beams bearing

onto stair landing edges. Additionally,

stucco panel areas at soffit beams and similar stucco bucket assemblies while

small in area, frequently exceed the Minimum Stucco Industry Standards for

stucco panel area proportions, potentially allowing cracks to occur that

allow water entry into the stucco bucket assembly.

Stucco Bucket

06: Stucco bucket at weather-exposed stairway landing beam. Stairwell open to the sky, angled stair

support tube directing water towards stair landing, with stucco bucket

configuration below. Note water

staining on exposed wood beam framing.

Stucco Bucket

07: Stucco bucket at weather-exposed recessed window head. This entire stucco soffit surface is a WES. Complicating

matters, building codes and Minimum Stucco Industry Standards do not

recognize this condition, or contain requirements to address and avoid stucco

buckets, even though they have been well-known in the forensics community for

many years. For

proactively addressing stucco buckets, a variety of standard soffit drainage

lath accessory or drainage screed flashing components are available as

solutions. Soffit drainage screeds are

available in all the typical lath accessory materials, in a range of

profiles, for integration with the WRB, to function as a soffit corner

drainage subassembly and direct water out of the wall assembly and divert it

away from the soffit.

Stucco Bucket

08: Soffit drainage screed (no perforations) installed above

weather-exposed recessed window head location.

Stucco

Bucket 09: Weather-exposed stucco soffit surface at recessed

window head location, with soffit drainage screed. |

||||||||||||

|

Stucco

buckets are a significant and common problem in the stucco industry and are

easily avoided. Products and methods

for draining weather-exposed, ground facing soffit corners are readily

available and should be provided at all stucco bucket conditions even if they

are not required by building codes and Minimum Stucco Industry Standards. |

||||||||||||

|

Minimum Standard of care: ·

Know the building code definition of a weather-exposed surface (WES). ·

Protect WES at soffits with a continuous WRB. Stucco Best Practices: ·

Avoid WES soffit surfaces where possible with building design. ·

Continuously ventilate soffit assemblies where possible to allow the

assembly to dry out if water does accumulate within it. ·

Provide a continuous, non-perforated, soffit drainage screed flashing

at ground facing, weather-exposed outer soffit corners, as part of a soffit

drainage subassembly integrated with the WRB, which provides a means for

draining water out of the wall assembly, diverting water away from the soffit

assembly. ·

Recognize configurations of construction that exacerbate stucco bucket

conditions and provide means of mitigating their effects, by reconfiguring

them, or providing additional waterproofing, flashings, soffit drainage

subassemblies or other means of drainage. ·

At long horizontal narrow stucco panel areas such as at spanning beams,

provide additional vertically-oriented SMJS subassemblies to define smaller

panel area geometries, to minimize cracks that allow water entry into the

stucco wall cladding system. |

||||||||||||

|

Consultation with licensed and experienced stucco professionals

is recommended for stucco-related endeavors.

No liability is accepted for any reason or circumstance, specifically

including personal or professional negligence, consequential damages or third

party claims, based on any legal theory, from the use, misuse or reliance

upon information presented or in any way connected with StuccoMetrics.com. |

Home Page Contact

Me Disclaimer