|

StuccoMetrics® |

Jeff Bowlsby CCS, CCCA

Exterior Wall and Stucco Consultant

Licensed

California Architect

Stucco Shrinkage Movement Joint

Subassembly (SMJS)

(“control joint”)

|

Webpage Quicklinks Terminology: "Control Joint" vs. SMJS

Subassembly Portland Cement-based Plaster

and Stucco Movements Purpose of the SMJS

Subassembly SMJS Subassemblies, Water

Intrusion and Water Management Open Stud Framing as Substrate Support Panelized

Sheathing over Framing as Substrate Support Substrate

Support Planar Tolerance and Shims Performance

Testing including Variant SMJS Subassembly Configurations Alternate Materials,

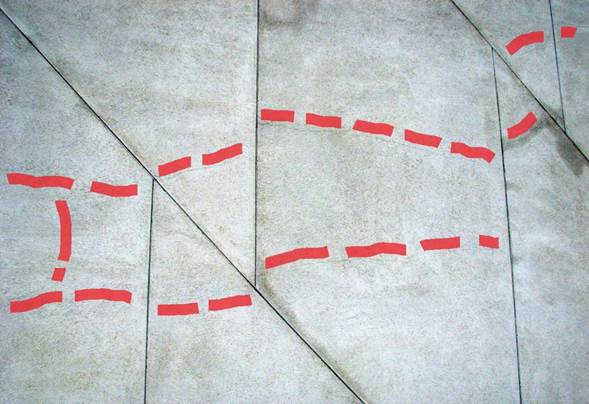

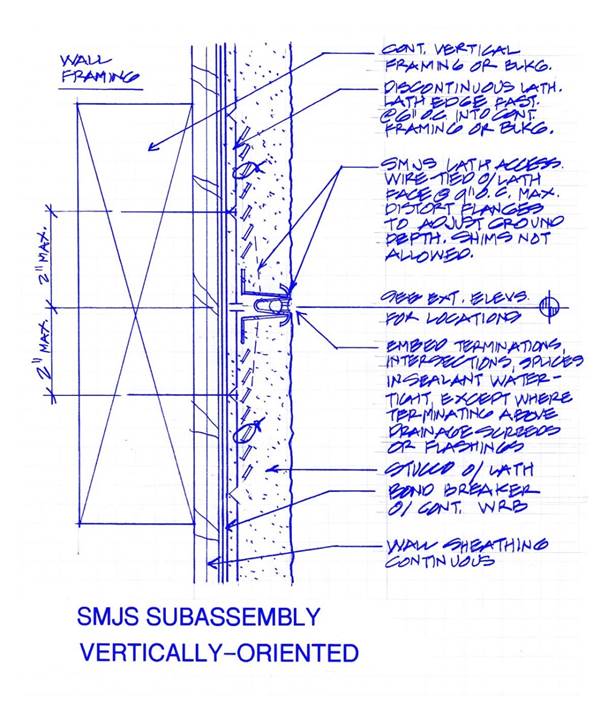

Designs, Tests and Methods of Construction Omission of SMJS Subassemblies Decorative Joint (DJ) Subassembly SMJS Subassembly at Panel Edges SMJS Subassembly within Panel Areas Horizontally-oriented SMJS Subassembly on Walls Vertically-oriented SMJS Subassembly on Walls Horizontal and Vertical Intersections Sealant at Splices, Terminations, Intersections Low-Slope

Weather-Exposed Surfaces A Case Study: Bringing

It All Together To Minimize Cracks Detail Drawings - SMJS Subassembly |

||||||||||||||||||||||||||||||||||||||||

|

This

webpage is dedicated to my ASTM C11 Committee colleagues To

determine which stucco movement joint is appropriate for a given condition,

one must understand the anticipated movement at the condition. Shrinkage and thermal movements occur in

the lath and stucco membrane. BMJS,

PMJS and SMJS each accommodate shrinkage and thermal movements because the

lath and stucco composite membrane is discontinuous through and terminate at

each side of these subassemblies. A

SMJS does not accommodate substrate support movement because the substrate

support is continuous at SMJS. BMJS

and PMJS accommodate substrate support movement because the substrate support

is discontinuous at these subassemblies.

Stucco Movement Joint

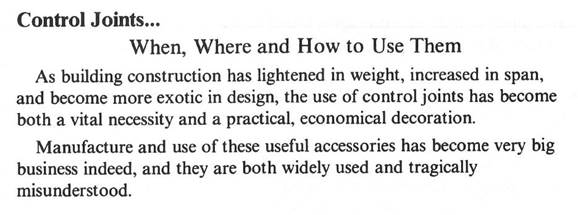

Selection Matrix Everyone

interested in exterior stucco wall cladding systems has a perspective on

“control joints” and those perspectives are not unilaterally held by

all. The vast array of information

about “control joints” can easily perplex and overwhelm, and the industry is

replete with a variety of differing viewpoints and oftentimes conflicting,

incomplete, inaccurate or obsolete information. Much of the information being circulated

and relied upon today was developed many years ago, and while perhaps based

on the best information available at the time, stucco research and technology

has advanced since then and now some of that information is obsolete or

better quality information is available.

Some current resources have innocently parroted other resources,

continuing the spread of conflicting, incomplete, inaccurate or obsolete

information and base opinions on this lack of correct information which is

unfortunate and is one cause of much strife in the industry on this

subject. We have the capability and

information available now to discern myths from reality. The

term “control joint” is vague and ambiguous and does not describe its primary

function initiating endless debates about what it is, what it does and how it

does it. The replacement term

Shrinkage Movement Joint Subassembly (SMJS) is used on this website which is

intended to better convey its essential association with shrinkage movement,

and significantly identify its role as a subassembly of a larger stucco wall

cladding system. A “control joint” is

not just a lath accessory bolted onto a wall.

It is a primary purpose of this webpage and website to convey

reasonable, credible, rationally-based and defensible information leading to

an understanding of the primary purposes of the SMJS subassembly, how it is

intended and required to function, and how it actually does function, that it

is hoped will resolve any lingering debate about its design, installation and

location requirements to be an effective stucco wall cladding subassembly

that serves its primary function towards minimizing stucco cracks. The SMJS subassembly, its intended purpose, function, and installation

configuration can be misunderstood amongst building owners, architects and

craftsman. If cracking did not occur,

stucco would be much more popular, respected and prolifically used as an

exterior wall cladding. These are the

intended outcomes of these webpages regarding stucco movement joints. Portland

cement-based plaster shrinkage and stucco thermal

movements are real and known causes of stucco cracking. If exterior stucco wall cladding systems

did not experience shrinkage or thermal movements,

then there would be only limited purpose for the SMJS subassembly. This webpage attempts to unpack and

evaluate the plethora of accurate and inaccurate information in circulation

and provide a rational, factual basis for providing correctly assembled,

functioning SMJS subassemblies, including information on SMJS subassembly

history, design, lath accessory and subassembly configuration requirements,

performance testing and the capabilities and limitations of the SMJS

subassembly that are useful towards minimizing stucco cracking and water

intrusion. Where the SMJS subassembly is the

primary means of accommodating cement-based plaster shrinkage and stucco thermal

movements, it is only when the SMJS subassembly is correctly located within a

stucco wall cladding system relative to wall openings and larger wall

expanses, and configured into panel areas of certain dimensions and

geometries that it creates a functional cement-based plaster shrinkage and

stucco thermal movement control Assembly.

While this webpage focuses on the SMJS subassembly it also covers the

essential parameters for a portland cement-based plaster shrinkage and stucco

thermal movement control Assembly. If a stucco wall cladding system did not

experience shrinkage and thermal movements, then there would be no essential

purpose for the SMJS subassembly. This

webpage explores the conditions that make the SMJS subassembly beneficial to

the success of an exterior stucco wall cladding system on a building as a

substrate support. Visit the StuccoMetrics Reference Archives

webpage for cited references and further information. |

||||||||||||||||||||||||||||||||||||||||

|

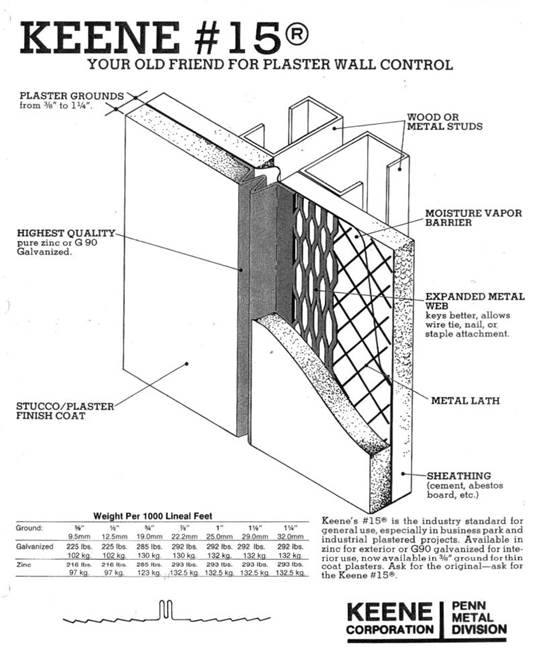

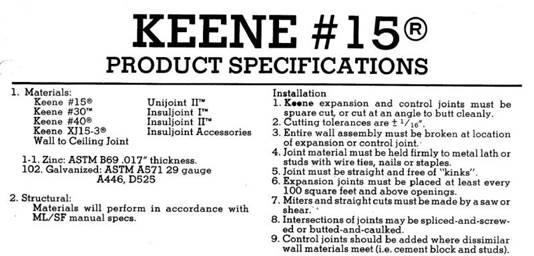

From Technical Manual, Keene

Corporation, Penn Metal Products, c.1980 From the earliest times when portland cement-based plaster first

began to be applied onto framed building structures, the biggest concern was

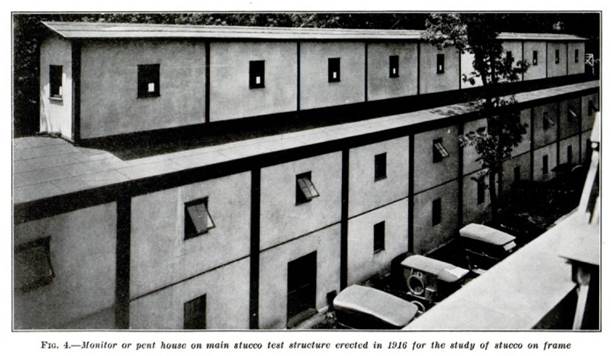

wall opening corner cracking at reentrant window/door corners. In the late 1910’s through early 1920’s,

the US Bureau of Standards, as part of the Department of Commerce, performed

a battery of testing on portland cement-based plaster and stucco wall

cladding and its Components because it recognized the potential and

importance of stucco to the economy and wanted to assist in its success as a

building material. The Bureau of

Standards constructed several full-sized test buildings with multiple test

panels of stucco to test and observe the performance of various combinations

of stucco components, lath types and materials, stucco mortar mix designs,

framing/sheathing type alternatives, and application and curing methods for

optimum results and minimized cracking.

A significant part of the stucco testing at this time was devoted to

evaluating the predominant stucco cracking conditions occurring at window

corners. During this era, stucco

cracking was most commonly attributed to building structure movements. Soil settlement and wind loads were also

suspected causes of cracking. Further

government testing determined that wood lath was a major cause of stucco

cracking and was ultimately replaced in the marketplace by expanded sheet

metal lath and wire lath. Various

board sheathing types and installation methods (to minimize building

movements) were evaluated, ultimately determining that horizontally-installed

board sheathing was the best method for sheathing a building for stucco

cladding to minimize reentrant window/door corner cracking. Yet despite these improvements, reentrant

corner stucco cracking persisted.

1916 US Bureau of Standards Stucco

Testing to evaluate window corner and stucco

panel cracking Patent research: Not all SMJS lath accessory components are patented and not all patented SMJS lath accessory components were produced or are currently available. Select SMJS lath accessory components and subassemblies are discussed.

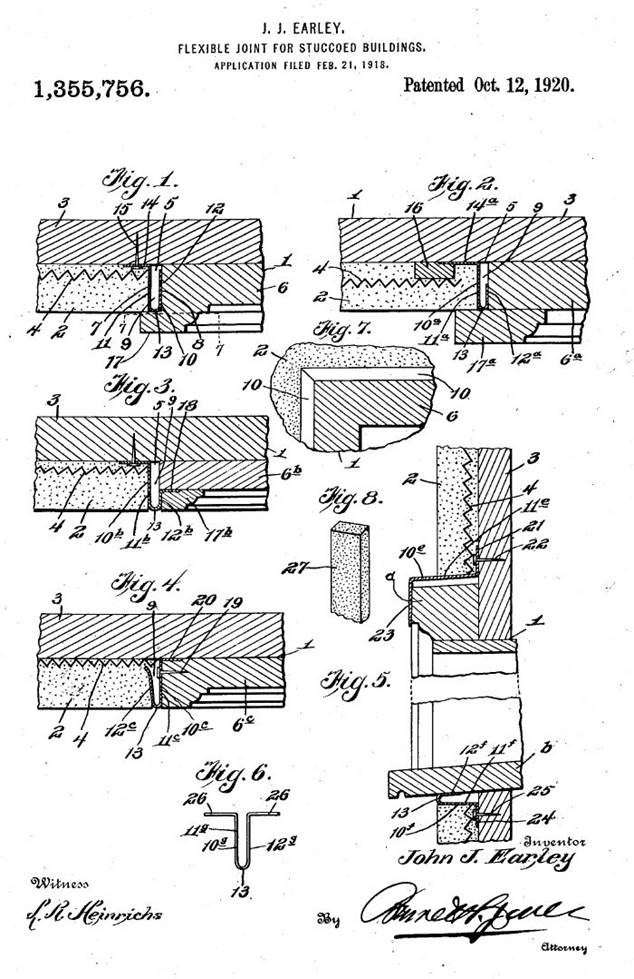

In 1920, inventor John Earley (who had participated in the Bureau of Standards testing

program) devised the first stucco movement joint lath accessory and SMJS

subassembly, Patent No. 1355756, Flexible

Joint for Stuccoed Buildings, for a flexible

metal joint screed lath accessory for use around window and door frames. Earley opined that

a building and stucco cladding were stable using board sheathing, therefore

stucco only cracked because the wood window/door frames and underlying

framing at these wall openings expanded due to water absorption and swelling

during seasonal wet/dry cycles, which put force on the stucco at window and

door corners, causing reentrant corner cracking. Earley’s screed

was intended to provide a safety compression zone and counteract the

window/door frame expansion forces, and prevent stucco cracking that was

prevalent at reentrant window and door corners. Yet reentrant corner stucco cracking

persisted.

First

stucco lath accessory patent to

address stucco cracking J.J. Earley, 1920 In the late 1940’s a serious stucco cracking problem was

reported to have developed at the massive Grand Cooley Dam project(1),

and the stucco community benefitted once again from a rigorous stucco system

testing program, underwritten by taxpayers.

Interior room suspended stucco ceilings cracked objectionably when

their lath was continuous through the ceiling/wall juncture and secured to

the adjacent concrete perimeter walls (the common practice of the day). It was discovered through extensive testing

of many variables, that the ceilings did not crack when the lath was

discontinuous at the ceiling/wall juncture, which allowed the ceilings to

shrink away from the walls. The

perimeter ceiling gaps that developed when the ceilings were isolated and

shrank away from the walls were large and measurable, but no ceiling cracking

occurred attributable to the isolated perimeter lath condition which was

deemed to be of great benefit in minimizing cracking at the ceilings. Discontinuous lath, which eliminated restraint conditions at

stucco ceiling panel perimeters of interior rooms, was

proven to minimize stucco cracking at Grand Coulee Dam. At Grand Coulee Dam lath

and stucco was installed as an unrestrained composite panel, which

accommodated shrinkage and thermal movements and minimized stucco cracking at

interfaces of different substrate supports.

The realized benefit of this newly developed discontinuous

method of lath installation became the new paradigm for stucco on framed

substrate supports to minimize cracking:

Stucco on framed substrate supports performed better with less

cracking when constructed as adjacent, discrete, segmented panels that

accommodate shrinkage and thermal movements within each panel, as compared to

a single, non-segmented, solid, continuous lath and stucco composite mass

cladding the entire building. The

stucco movement joint subassemblies pertaining to transitions between

different substrate support materials or loadbearing conditions, or building

substrate movement conditions are known on this website and BMJS and PMJS

subassemblies. Stucco movement joints

pertaining only stucco cladding shrinkage and thermal movement where the

substrate support is continuous and produces no substrate movement, is known

on this website as a Shrinkage Movement Joint Subassembly (SMJS). The SMJS subassembly was formed by adjacent

casing beads with discontinuous lath, which is a SMJS subassembly still

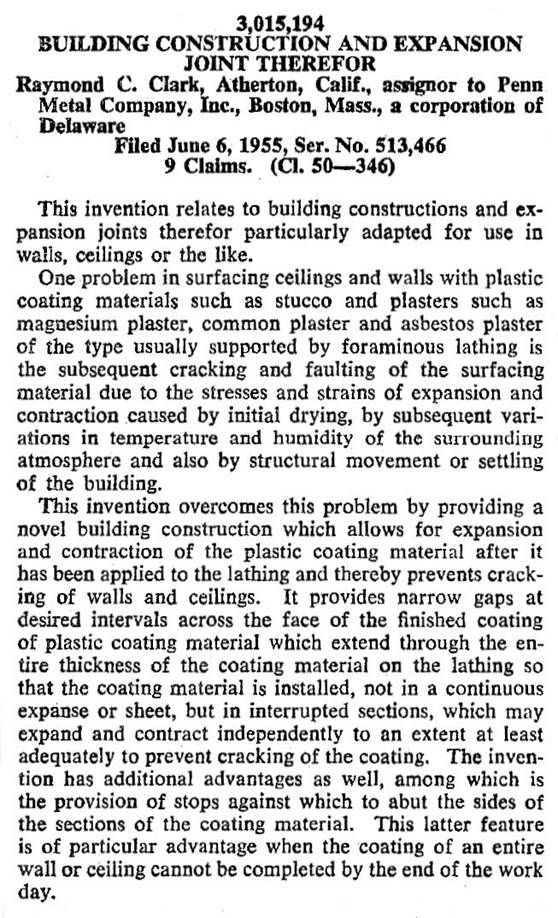

recognized by Minimum Stucco Industry Standards today. By the mid-1950’s portland cement-based plaster shrinkage and

stucco thermal movement were recognized causes of cracking. The one-piece stucco SMJS lath accessory

component was developed and brought to market as a more convenient form than

the two-casing bead configuration. The

one-piece SMJS lath accessory component invented by Raymond Clark(2)

was filed for Patent No. 3,015,194 in 1955, and the patent was granted in

1962. This product is known today as

the Double-V lath accessory, and generically as a SMJS lath accessory

component on this website. The

Double-V SMJS lath accessory component features an expansible, resilient

pleat at its center with expanded sheet metal flanges to each side for keying

the SMJS lath accessory component to the adjacent lath edges as the result of

discontinuous lath. The anticipated

behavior of the continuous lath was described in numerous locations

throughout the patent as “expansible” and was considered to be the primary

zone of movement along with the pleat of the lath accessory component. The SMJS lath accessory component is of a

vertical height dimension sufficient to function as a plaster thickness

ground screed and its configuration provides a convenient location to stop

plastering work where needed, to avoid the need for “joinings” (cold joints)

in the plaster. The Penn Metal

Company, and later the Keene Corporation and Metalex which later acquired

Penn Metal Company, were the original manufacturers of this original

one-piece SMJS lath accessory component.

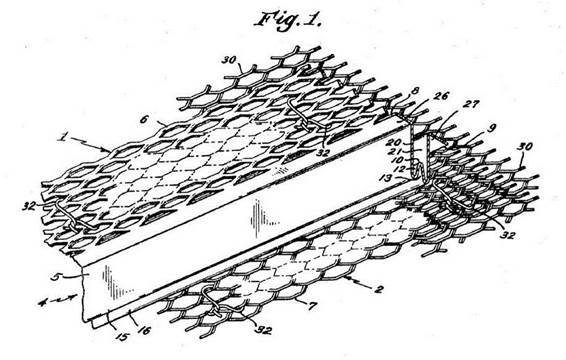

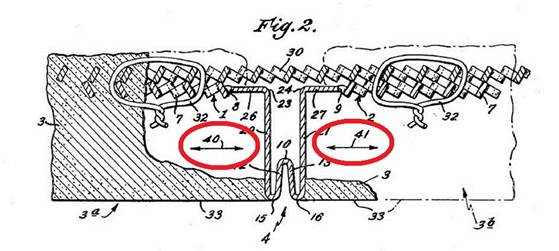

Illustrations from

Clark Patent 3,015,194 (Note

the patent illustrates both a SMJS lath accessory component and

SMJS subassembly. The SMJS lath

accessory is wire-tied to continuous lath.

Arrows 40 and 41 depict anticipated SMJS subassembly movement

behavior.) From

the Clark patent the SMJS lath accessory and SMJS subassembly functions as

follows: “…due to the stresses and

strains of expansion and contraction caused by initial drying, by subsequent

variations in temperature and humidity of the surrounding

atmosphere...”. “It provides narrow

gaps at desired intervals across the face of the finished coating of [stucco]

which extend through the entire thickness of the [stucco] on the lathing so

that the [stucco] is installed, not in a continuous expanse or sheet, but in

interrupted sections, which may expand and contract independently to an

extent at least adequately to prevent cracking of the [stucco]”. In

the Clark patent, the pleat is described as a “resilient fold”, it was intentionally designed and described to function

similar to an accordion – opening and closing, in response to the movements

of initial stucco shrinkage and thermal expansion and contraction while in

service. The SMJS lath accessory has

expanded sheet metal flanges which key the stucco to the lath and SMJS lath

accessory just as the lath does; it creates a flexible extension of the lath,

in the plane of the lath. Clark termed

this invention an “expansion joint” in his patent and this term is used in

many of the Penn Metal, Keene, Metalex catalogs.

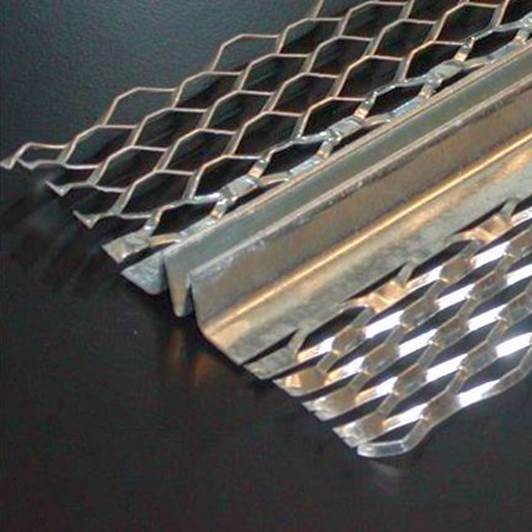

SMJS lath

accessory, Double-V A variant of the original SMJS lath accessory is the Double-V,

Internal Corner SMJS lath accessory component, developed in the early

1960’s. It is nearly identical to the

Double-V SMJS lath accessory other than its flanges are configured into a 90

degree to nest into an internal wall corner.

SMJS lath

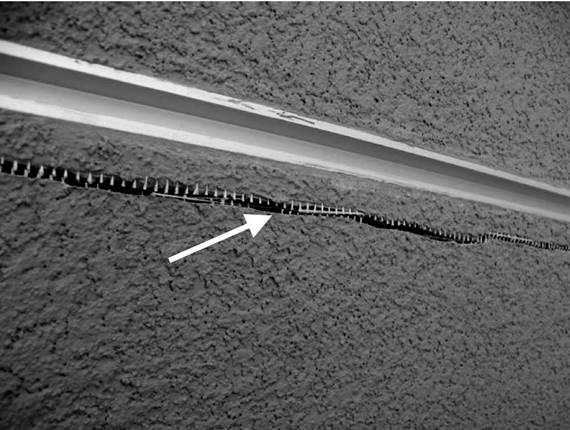

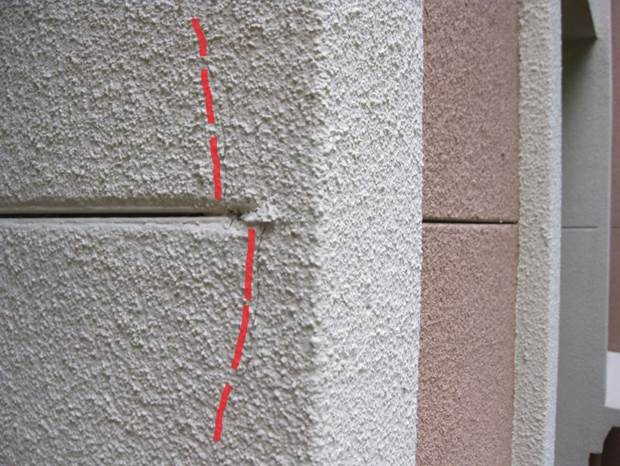

accessory, Double-V Internal Corner Soon after the Double-V SMJS lath accessory

component was introduced, it was observed that as its center pleat opens and

closes from initial portland cement-based plaster shrinkage and stucco

thermal movements, linear, parallel gaps can form at one or both edges of the

pleat. These parallel edge gaps are an

aesthetic distraction and may allow bulk water penetration into the stucco

wall cladding system. By about 1969 Penn Metal Co. had been acquired

by the Keene Corporation and in 1978 Keene brought an improved version of the

Double-V SMJS lath accessory to market, with the proprietary designation as

the Keene XJ15-3 and generically known as the Double-J SMJS lath

accessory. The Double-J SMJS lath

accessory is identical to the Double-V SMJS lath accessory, except it has

additional locking edge flanges that grip the stucco edges of each adjacent

stucco panel on both sides of the SMJS subassembly. This locking edge capability minimizes the

parallel gaps that can form at the stucco panel edges that the Double-V SMJS

lath accessory can experience when portland cement-based plaster shrinks away

from it or stucco thermal movement occurs, and also conceals the parallel

gaps to minimize the potential for water intrusion through the parallel edge

gaps. No separate patent for this

improved lath accessory is known to exist.

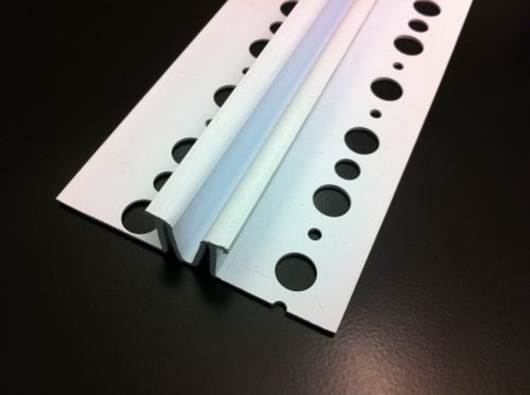

SMJS lath

accessory, Double-J

SMJS lath

accessory, Double-J, PVC The

SMJS lath accessories depicted above are available from several manufacturers

today, in a variety of corrosion-resistant materials including galvanized

steel, solid zinc alloy, stainless steel, extruded PVC and are available in a

range of ground dimensions for various stucco panel thickness

requirements. Other

SMJS lath accessory inventions after Clark, were either not commercially

successful or may have been mistakenly inferred to be SMJS lath accessories,

but were intended for larger movement conditions related to substrate support

movements and therefore are considered Building Movement Joint (BMJS) lath

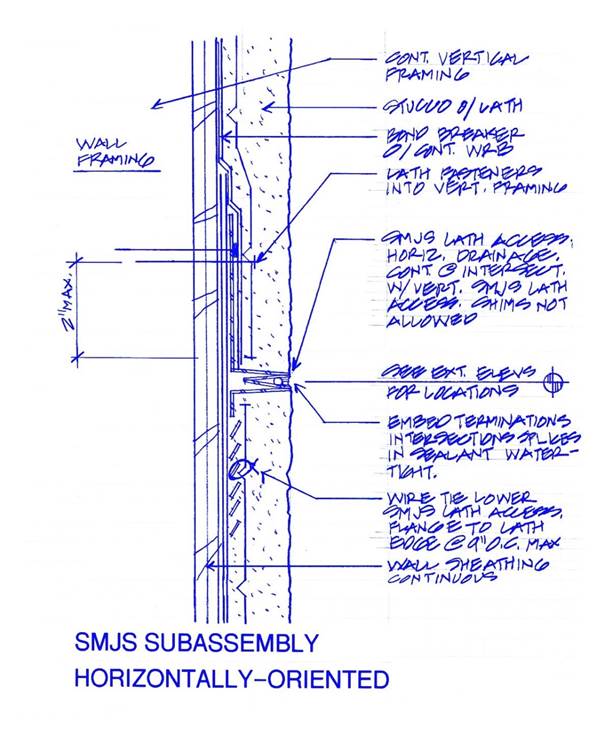

accessories and subassemblies as described on this website. In 2008 the SMJS lath

accessory and subassembly evolved further when Mr. Don Pilz

of Cemco brought a number of lath accessories and

water management flashings to market, including the innovative Cemco Solid Leg #15 lath accessory(3). Generically referred to as the Double-V Horizontal Drainage SMJS lath accessory, it is most similar to a Double-V SMJS lath accessory, but it

also includes a solid flange to integrate with the WRB which allows it to

function as a horizontally-oriented drainage screed flashing for stucco wall

cladding systems. This innovation is

designed for use typically as a horizontal SMJS subassembly only, for use at

design locations on walls occurring between the foundation drainage screed

and the top of wall. It has dual

function as both a horizontal drainage screed lath accessory because it is

integrated with the WRB, and as an SMJS subassembly to minimize cracking

related to shrinkage and thermal movements.

SMJS lath

accessory, Double-V Horizontal Drainage (Cemco

Solid Leg #15) From the Stucco Material Properties webpage, we learn that the combined portland cement-based plaster shrinkage movement and stucco thermal movement accounts for approximately 130-240 mils (0.13-0.24 in.) per 10 lineal feet, or 13-24 mils per lineal foot of stucco wall cladding. The Clark patent documentation clearly describes in written and

graphic form the SMJS lath accessory intended configuration and function as a

SMJS subassembly. The lath of the SMJS

subassembly expands and contracts along with the portland cement-based

plaster shrinkage and stucco thermal movements because the two are one

composite material. The new invention

was described as being applicable for both walls and ceilings and is wire-tied

to the face of the lath. The lath was

described as being “expansible” and the SMJS lath accessory was described as

being “resilient” to accommodate movement which was anticipated by Clark to

occur at SMJS subassemblies and SMJS lath accessories. It is essential to recognize and understand

that Clark devised not only the SMJS lath accessory, but also the SMJS

subassembly which includes the SMJS lath accessory in a specific installed

configuration with other components of the subassembly such as the substrate

condition, lath, fasteners and of course the cement-based plaster, a fact

often overlooked. Lath

accessory product catalogs from the Penn Metal Company, Keene Corporation and

lastly Metalex (all were the original producers of the SMJS subassembly) provide

the first glimpse of SMJS subassembly installation requirements as provided

by the manufacturer. A manufacturer’s

installation requirements for their products are generally regarded as an

authoritative resource in the construction industry. In the timeline that follows, the

requirements described remain in effect until changes and additional

requirements are noted in subsequent catalog issues. These original SMJS lath accessory

manufacturers issued installation requirements for the SMJS lath accessory

product from at least 1959 through about 2005. SMJS lath accessory manufacturers no longer

publish SMJS subassembly installation requirements. Instead, since the 2006 IBC building code

has adopted ASTM C1063, this Minimum Stucco Industry Standard is the current

authority and reference resource on SMJS subassembly installation

requirements wherever the IBC building code is in effect.

1959-2005 Penn Metal Company, Keene Corporation, and Metalex catalogs It is interesting to review and understand the progression of

“control joint” installation requirements, because they subtly changed as

they were introduced over many years from the Penn Metal Company, Keene

Corporation, and Metalex product catalogs, and to compare them to the

requirements in the ANSI and ASTM specifications of the day up through today: ·

1955: “Expansion joint” lath accessory introduced

to market, patent issued in 1962. ·

Through early

1960’s: No installation requirements

provided in product catalogs, the only guidance was described in Clark’s

patent documentation. ·

1964: Maximum spacing for “control joints” is

“generally 8 feet.” Solid zinc lath

accessory was made for salt laden environments. ·

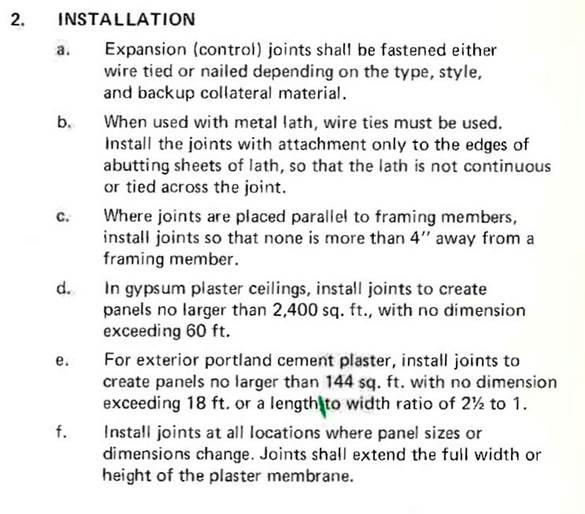

1971: “Install

“joints” at all locations where panel sizes or dimensions change. Joints shall extend the full width or

height of the plaster membrane.” ·

1973: Locate “control joints” where dissimilar

materials join, where substrates support conditions change such as suspended

ceilings to perimeter walls, 100-125 SF areas maximum, above door bucks and

into the ceiling juncture on both sides of heavy frames or where heavy doors

and hard use will be encountered.

Maximum panel geometry 2-1/2 to 1.

“All (Plaster-Stucco) expansion joints shall be installed…to provide a

movement capacity of 1/4 in.” ·

1974: Only zinc shall be used at exterior

locations, and the following requirements:

·

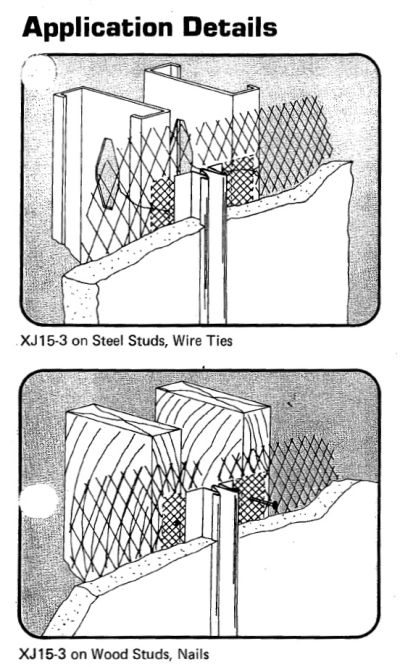

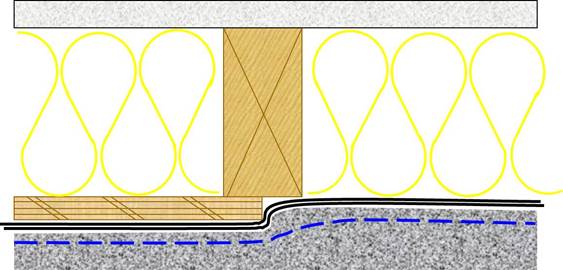

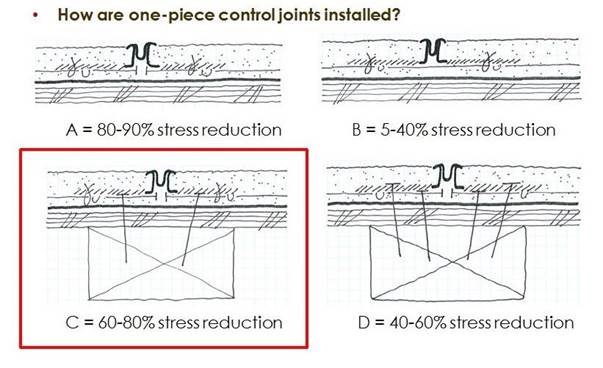

1978:

1978: Note discontinuous lath,

separate (doubled) studs, no sheathing, “control joint” lath

accessory wire-tied or nailed to/through lath edges and

into studs ·

1983: Expansion joints must be placed at least

every 100 SF and above door bucks as noted previously. Intersections of joints may be

butted-and-calked and the following:

From 1983 Keene

Corporation catalog

1983 Keene

Corporation product data (Note

discontinuous lath, separate (doubled) studs, discontinuous sheathing, fasteners

for “control joint” lath accessory not indicated) ·

1985: “Joint materials must be held firmly to metal

lath or separate (double) studs with wire ties, nails or staples.” ·

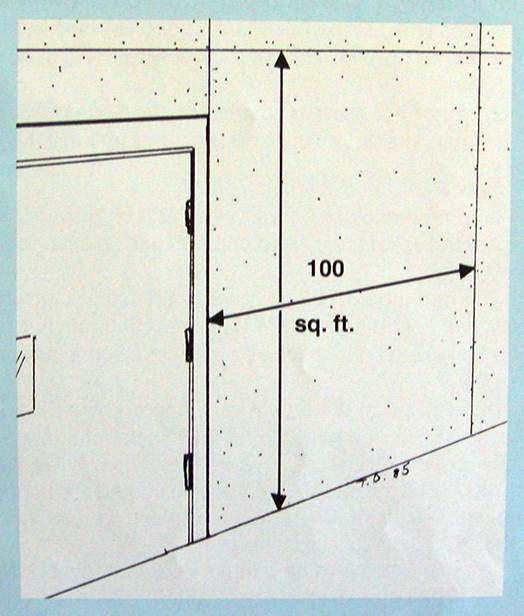

1990: Maximum panel area recommendation, 100 SF

(not 144SF), square, and aligned with wall opening corner:

From 1990’s Keene

Corporation Catalog (Note

SMJS aligning at door opening corner, panel

area size and geometry) F ·

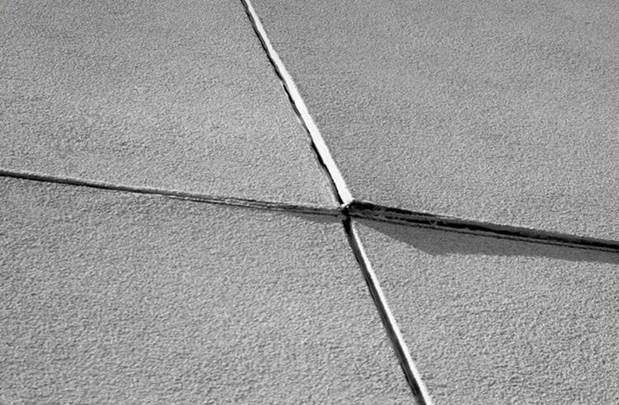

1994-2005: Where vertical and horizontal “control

joints” intersect, the vertical joint should remain continuous and

unbroken. Screws are not mentioned as

an acceptable fastener either for lath edge fastening or fastening the

“control joint” lath accessory. ·

Sometime after 2005

Metalex ceased providing “control joint” products direct to the market, and

hence product literature, but they continue to manufacture “control joints”

and other lath accessories and provide them to other lath accessory

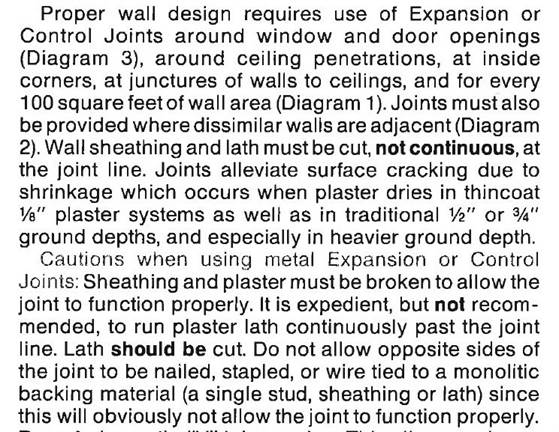

manufacturers that distribute them. Keene Corporation published a Technical Manual(4), c. 1980, as a general guide to

“control joints”. Unlike other Keene

documents of the era, this document is primarily a narrative and written in a

language style more as a guide than specifying technical requirements. Interestingly, the term “control joints” is

identified and intentionally used exclusively by Keene in this document after

discussing other terms used in the era, for stated consistency reasons. None the less the manual does present the

following technical installation requirements, “…a control joint…must be

used...”: ·

Where dissimilar

materials join ·

Where a large

suspended ceiling is pierced by supporting beams or columns ·

“Where

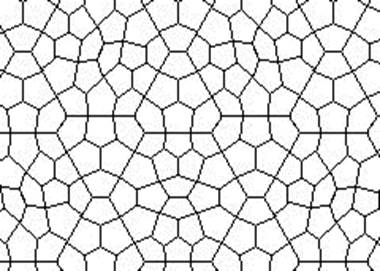

portland cement plaster is involved, for allowance must be made for the

inherent shrinkage in portland cement.

In this instance areas of not more than 100-125 square feet are

recommended on the premise that small areas disassociated from one another

will allow for this shrinkage with no unsightly fracturing and that if the

areas are isolated from one another and small enough to come and go without

restraint, there will be no problems.” ·

Above door bucks and into the

ceiling juncture on both sides of heavy frames ·

Around large

penetrations such as light troffers, heavy access panels, etc. ·

Discontinuous lath

is required at “control joints”.

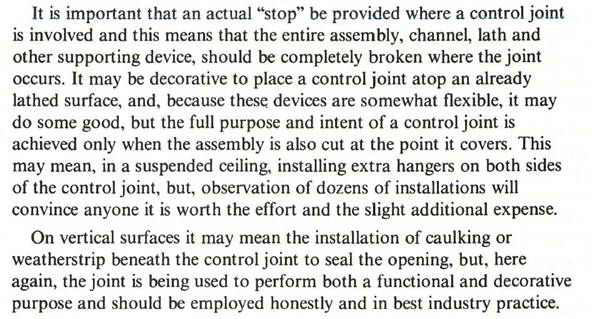

“Walls and ceilings that use metal reinforcement for the base should

be divided with a “control joint”… The metal reinforcement in the stucco or

plaster must be separated and not extend across these “control joints”.” And the following:

·

“Walls and ceilings

that use metal reinforcement for the base should be divided into rectangular

panels with a control joint at least every 20 ft.” [No basis for that 20 ft. dimension

is mentioned]. Minimum

Stucco Industry Standards for stucco wall cladding systems are indicated below.

Readers are encouraged to purchase the referenced

ASTM Standards directly from ASTM and review them. The referenced ASTM Standards and texts are

indicated for reader’s convenience, for purposes of topical discussion. Requirements

of the Standards are paraphrased, written in the imperative mood and

streamlined writing format as is recommended by the Construction

Specifications Institute (CSI) and common to construction specifications,

using the terminology developed and described on StuccoMetrics.com. ASTM C1007 Standard

Specification for Installation of Load Bearing (Transverse and Axial) Steel

Studs and Related Accessories(5): ·

(7.1) Vertical stud

alignment (plumbness): 1/960 of span (1/8-in. in 10-ft 0-in.) ·

(A2.4) Allow additional studs at panel

intersections, corners, doors, window, SMJS, etc. ASTM C1280 Standard Specification for Application

of Exterior Gypsum Panel Products for Use as Sheathing(5): ·

(8.2.1.1) Offset gypsum

panel edge joints at wall opening corners 4-in. (100-mm) minimum. ASTM C1063 Standard Specification Installation for

Lathing and Furring to Receive Interior and Exterior Portland Cement-Based Plaster(5): ·

(3.2.3) SMJS, noun:

A movement joint subassembly accommodating minor movement associated

with plaster shrinkage and curing along designated lines. ·

(7.5.4) Main runner splices: Nest channel flanges and overlap channel

ends 12-in. (305-mm) minimum. Securely

install ties near splice ends with double loops of either 0.0625-in.

(1.59-mm) or twin strands 0.0475-in. (1.21-mm) galvanized wire. For splices located at BMJS and SMJS,

loosely install ties holding splice together to allow for movement. ·

(7.6.5) Splice main runners and cross furring at

BMJS, SMJS. Reference 7.5.4 ·

(7.10.1.5) Discontinue lath through SMJS, and attach

the lath edges to the substrate support at each side of the SMJS. ·

(7.11.4) SMJS subassembly: A plaster separation gap 1/8-in. (3.2-mm)

minimum or as required by anticipated shrinkage and thermal movement,

conforming with 7.10.1.5 using a one-piece manufactured SMJS lath accessory

or back to back casing beads configured over a flexible barrier membrane. ·

(7.11.4.1) SMJS assembly: Install and configure SMJS subassemblies

into plaster panels with surface areas not exceeding 144-ft2 for

walls and 100-ft2 for horizontal applications such as ceilings and

soffits. ·

(7.11.4.2) Maximum plaster panel dimension and

proportion: 18-ft. (5.5-m) panel

dimension, 1:2.5 panel length to width

proportion. Provide SMJS at ceiling

framing or furring directional changes. ·

(7.11.4.4) Plaster panel edges at floor to ceiling

height door frames are SMJS. ·

(A1.2) Provide BMJS, PMJS to accommodate building

substrate movement and to minimize movement related stucco and WRB damage. ·

(A1.3) Provide SMJS to minimize plaster shrinkage,

curing stress and minor movement, along designated, typically straight lines

and as a plaster thickness control screed. ASTM C926 Standard Specification for Application

of Portland Cement-Based Plaster(5): · (7.1.5) Apply plaster

continuously at walls and ceilings to avoid cold joints and abrupt appearance

changes in each plaster coat. Abut wet

plaster to set plaster at planar interruptions such as corners, rustications,

openings, BMJS, PMJS and SMJS where possible.

Cut joinings, square and straight, 6-in. (152-mm) minimum away from

joining in previous coat, where they are necessary. ·

(A2.1.3) Seal separation gaps between weather

exposed plastered panel edges and dissimilar materials to prevent water

penetration. ·

(A2.3.1) Reference the Installation Section of

Specification C1063 for PMJS and SMJS installation requirements used with

metal plaster base. PMJS and SMJS are

not required at solid plaster bases, except as stated in Specification C1063

7.11.4.3. ·

(A2.3.1.1) Remove plaster from pleat area of SMJS

before applied plaster hardens. ·

(A2.3.1.2) Evaluate the

characteristics of the substrate and indicate the requirements for BMJS, PMJS

and SMJS on construction documents, including type, location, depth,

installation requirements. Install

BMJS, PMJS and SMJS before plastering. ·

(A2.3.1.3) A groove in

plaster is not a BMJS, PMJS or SMJS. ·

(A2.3.3) Provide a BMJS, PMJS or SMJS at transitions

between dissimilar substrate support materials that receive continuous

plaster. In addition, various non-codified

stucco industry reference resources establish a strong precedent for stucco

wall cladding systems to include “control joints”: PCA Portland Cement Plaster / Stucco Manual, EB049: ·

A

narrative description of requirements for “control joint” usage and

installation requirements identical to those stated in ASTM C1063 and C926 ACI Guide to Portland Cement-Based Plaster, ACI 524R: ·

A

narrative description of requirements for “control joint” usage and

installation requirements identical to those stated in ASTM C1063 and C926 ·

“Specify

and detail measures to minimize plaster cracking, including…Proper location

of “stress-relief joints” in accordance with ASTM C1063; additionally,

“control joints” at re-entrant corners may be recommended, though not

required by code”. ·

“Stress-relief

joints” should be located…where cracking is more likely to occur: 1. Headers

and sill corners of windows, doors and other architectural projections or

penetrations into plaster; 2. Edges

and corners of ventilation or heating vents; 3. Structural

plate lines or concentrations of large timber members in wood construction; 4.

Midpoints between frame supports or midpoints between maximum

control-joint spacings 5.

Junctures where main columns or structural beams meet walls or

ceilings; 6.

Plastering over “expansion joints” or “control joints” of a solid

plaster base; or 7.

Plastering over

junctures of dissimilar plaster bases.” ·

“Terminations

or splices in “stress-relief joints” should be embedded within a

weather-resistant elastic sealant to prevent moisture penetration.” ·

“Specify

and detail the installation of flashing, weep screeds, and sealant at doors

and around windows, vents, and all other wall penetrations to ensure that water

will be diverted or channeled to the outside of the wall assembly in

accordance with ASTM C1063 and E2112.” ·

“Specify

and detail the use of sealant at “stress-relief joint” terminations and

splices” ·

“Specify

and detail the use of sealant at wall penetrations to prevent leakage at

these points.” EMLA 920-09 Guide Specifications for Metal Lathing and Furring: ·

A

narrative description of requirements for “control joint” usage and

installation requirements identical to those stated in ASTM C1063 and C926 ·

“Joinery

of abutting ends of trim accessories should be spliced or lapped and sealed

with appropriate sealant.” ·

“Joinery

of “control joint” intersections should be spliced or lapped and sealed with

appropriate sealant.” ·

““Control

joints” should be sealed at inside/outside corners and termination points.” ·

“Less

than ceiling height door frames shall have “control joints” extending to the

ceiling from both top corners, or ceiling height

door frames may be used as “control joints.”” ·

“All

intersections and terminations of “control joints” must be embedded and

weather sealed in a bed of caulking material.” |

||||||||||||||||||||||||||||||||||||||||

|

A stucco wall cladding system can be constructed

without SMJS subassemblies, but this practice is only applicable to

direct-applied, continuously-bonded portland cement-based plaster onto mass

masonry or solid concrete substrate supports.

No WRB is used in this stucco wall cladding system; the mass of the

wall is the weather protection as allowed by the building code. Stucco applied in this manner is intended

to be continuously bonded to its substrate, is an acceptable method for

applying stucco onto a mass masonry or solid concrete substrate and has

performed well as an assembly for centuries.

It must be mentioned that solid concrete or masonry buildings can be

vulnerable to cracking and some have cold joints expressed at the surface,

either condition of which can be vulnerable to water intrusion. Relatively few buildings are constructed

with mass masonry or solid concrete walls in many parts of the USA, the

southeastern and tropical USA regions being exceptions. Higher performance finish coatings can be

applied if water intrusion through these solid wall assemblies is a

concern. Generally, this wall

assembly, without high performance exterior coatings is most appropriate for

where some tolerance for water intrusion may be acceptable, such as for unconditioned

parking garages, industrial or utility buildings. Stucco on framed or framed/sheathed

building substrate supports however behaves in an entirely different manner

than when directly-applied to solid concrete or mass masonry substrates. Stucco cracking at wall opening reentrant

corners such as window and door corners has been problematic for stucco on

framed or framed/sheathed substrate

supports since the earliest use of stucco on framed or framed/sheathed

buildings. At the time, stucco on wood

lath and later metal lath, was applied continuously over all framed or

framed/sheathed substrate supports without interruptions, as if it were

emulating stucco directly-applied to mass masonry or solid concrete

buildings. The earliest causes of

stucco cracking on framed or framed/sheathed buildings were commonly regarded

to be building movement and expansion of wood windows due to water

absorption. Stucco

cracking remains a concern by a variety of interests in the building industry

today. Stucco crack typologies suggest

patterns of recurring cracking conditions that can be addressed during stucco

wall cladding system design and construction.

It can be a challenge to correctly identify stucco shrinkage and

thermal movement stress concentration conditions with 100% accuracy for

strategically locating SMJS, but obvious and typical patterns and conditions

exist that can be addressed. Primary

design and installation considerations include conditions such as

non-functional SMJS, reentrant wall opening corners at windows, doors,

louvers etc., maximum stucco panel areas, dimensions and geometries, SMJS splices, intersections and terminations, three-plane intersections, and stucco

cladding penetrations. Reference the Stucco Cracks webpage for further information. Minimum Stucco Industry

Standards ASTM C1063 and C926 as referenced in the building code or as

specified in contract documents, provides the minimum prescriptive-based

design and installation requirements for SMJS. SMJS lath accessory manufacturers do not publish

engineering information, performance testing information or installation

instructions for SMJS lath accessory products. Other stucco industry

reference resources suggesting design and installation conditions for SMJS, where

they conflict with Minimum Stucco Industry Standards, codified as ASTM C1063

and C926 requirements, ignore basic behavioral characteristics of portland

cement-based plaster shrinkage and stucco thermal movements. In the late 1940’s, the role of

portland cement-based plaster shrinkage and stucco thermal movements in

stucco cracking became better understood.

Lessons learned included that separating stucco and lath composite

panels into segregated, discrete panels of smaller areas, eliminated the

perimeter edge restraint of the once continuous lath to accommodate shrinkage

and thermal movements, which minimized cracking. It was proven by extensive field testing

which evaluated a number of factors, that continuous, restrained lath at

perimeters of stucco panel areas exceeding a certain area or geometry, caused

stucco panel area cracking. Stucco

panel area perimeters were defined by a new isolation joint subassembly

configuration consisting of paired casing bead lath accessories, and the lath

was terminated or discontinuous at the isolation joint subassembly to

accommodate portland cement-based plaster shrinkage movement and stucco

thermal movement to minimize cracking.

Keep in mind that these initial example installation conditions,

evaluation and follow-up testing concerned a stucco and lath composite,

wire-tied to a suspended ceiling grillage, conditions that are about as ideal

as possible for isolating shrinkage and thermal movement from the substrate

support, and quite different from a lath fastening and load transfer

perspective than a stucco clad wall system where the lath is nailed, stapled

or screwed, where the gravity load of the stucco is transferred in shear

through lath fasteners to framing in the substrate support. The Clark patent describes the functional purpose and a general

description of the “control joint” lath accessory component and subassembly,

but provides little other substantive installation requirement

specifics. The SMJS lath accessory

component and subassembly were brought to the marketplace by a succession of

companies over many years, Penn Metal Company, Keene Corporation, and

Metalex. The Penn Metal Company, Keene Corporation, and Metalex manufacturers’ product

catalogs from at least 1959 through 2005 included “control joint”

installation instructions which indicate a number of consistent requirements

that did not change much in over 45 years of publication. But also indicated are subtle, progressive

variations in other important “control joint” installation requirements over

that same time span, which have certainly contributed to the struggles the

stucco industry has historically had concerning “control joints”. For example the following is a compiled chronology

of published installation requirements from Penn Metal, Keene and Metalex

over the years they produced and marketed the SMJS lath accessory and

subassembly: ·

Consistent: From 1971 forward, the stated requirement

to provide joints at “locations where panel

sizes or dimensions change” is a reference to panel shape or geometry. This requirement describes irregular panel

area geometries such as C-shaped, L-shaped and doughnut, all of which contain

reentrant corners. The requirement is

to avoid panel area geometries with reentrant corners. ·

Consistent: The stated requirement for discontinuous

lath at “control joints” did not change since it was first mentioned in 1973. ·

Consistent: The stated requirement for “control joint”

locations above door bucks and into the ceiling juncture on

both sides of heavy frames (reentrant corners), later described as above wall

openings and window openings did not change since it was first mentioned in 1973. ·

Consistent: The

stated requirement for maximum stucco panel area geometry of 2-1/2 to

1 and 18 LF maximum panel dimension did

not change since it was first

mentioned in 1973. ·

Consistent: Throughout the over 45 year history of the

Penn Metal-Keene Metalex SMJS lath accessory installation publications the

accessory is indicated to be installed over the lath, not mounted to the wall

first with the lath over it and not shimmed. ·

Variable: The inconsistent and interchangeable use of

different terminology on what exactly to call this lath accessory and/or

subassembly – “control joint” or “expansion joint” and other terms. ·

Variable: Written descriptions and graphic

illustrations that depict subassemblies of related components including the “control

joint” lath accessory in several different subassembly configurations. The lath, fasteners, framing and sometimes

sheathing and a WRB are indicated. ·

Variable: Variations in fastening requirements for

the “control joint” lath accessory from the patent application in 1955 where

the lath accessory was required to be wire-tied to the face of lath, to 1974

when it was depicted as nailed to framing, to 1978 when each flange was

depicted to be nailed or wire-tied to separate framing (double studs) where

sheathing is not installed. In 1983

staples were identified and allowed, and also the clarification, “When used

with metal lath wire-ties must be used.

Install the joints with attachment only to the edges of the abutting

sheets of lath, so that the lath is not continuous or tied to across the

joint.” ·

Variable: In 1983 it was first mentioned to require

that lath, sheathing and the “entire wall assembly” be discontinuous

including the requirement that the adjacent lath edges not be fastened to the

same framing member, effectively requiring double studs. This new requirement for discontinuous

sheathing and separate framing at “control joints” is a giant conceptual leap

from Keene’s original vision of “control joints” that only accommodated

portland cement-based plaster shrinkage and thermal movements, to “control

joints” that accommodated building substrate support movement – a joint we

now term as an “expansion joint” in ASTM C1063 today, or preferably a BMJS or

PMJS as used on this website. ·

Variable: “Control joint” spacing requirements, which

determine maximum stucco panel areas: è

Beginning

with the 1959 Penn Metal catalog: No

spacing or panel area requirements were initially indicated. è

1964-71

Penn Metal catalogs: “Maximum spacing

for exterior stucco is generally 8 feet.”

64 SF panel areas(?), no conditions or other justification for the

spacing is indicated. è

1973-74

Keene catalogs: “Where portland cement

plaster is involved, for [sic] allowance must be made for the inherent

shrinkage in portland cement. In this

instance areas of not more than 100-125 square feet are recommended on the

premise that small areas disassociated from one another will allow for this

shrinkage with no unsightly fracturing and that if the areas are isolated

from one another and small enough to come and go without restraint, there

will be no problems.” Later, these two

catalogs indicate the conflicting requirement: “…install joints to create panel no larger

than 144 SF…”. è

1977

Keene catalog: Identical text to the 1973-74

catalogs for 100-125 SF maximum panel areas, but the later indication of 144

SF is not mentioned in this or later Keene catalogs. è

1978-80

Keene catalogs: “Where portland cement

plaster is involved, there is an inherent shrinkage expected. “Expansion joint” should be spaced to allow

areas of not more than 100-125 square feet.

Unsightly fracturing is less likely to happen as long as wall/ceiling

surface areas are small and disassociated to “come and go” without

restraint.” è

1983

Keene catalog (Sweets): “For exterior

portland cement plaster, install joints to create panels no larger than 125

sq. ft….” è

1983-90

Keene catalogs including product data for Keene #15 and Unijoint

II, a separate loose leaf catalog, and the later years Sweets catalogs: “Expansion joints must be placed at least

every 100 square feet…” è

1994

Keene-2005 Metalex catalogs: No

spacing or maximum panel areas indicated. è

Note

that only the 1973-74 Keene catalogs indicate two different conflicting panel

area maximums and are the only references to 144 SF maximum panel areas in

the Keene product literature. Even

though Keene product literature reverted back to smaller panel areas in

1983-85, the first official 1986 ASTM C1063 indicates 144SF which remains

unchanged to this day. The lack of

change back to 100 SF after 1985 is not explained in stucco industry

literature. è

Note

that Keene produced their “control joint” lath accessories in both galvanized

steel and solid zinc alloy, and no mention of different “control joint”

spacing requirements based on different material performance is ever

mentioned. Minimum

Stucco Industry Standards ASTM C926, C1007, C1063 and C1280 are referenced standards in the building code which state minimum installation requirements for

SMJS lath accessories and subassemblies. From ASTM C926 we note: ·

7.1.5: “Control joints” are a naturally occurring

interruption in the plane of the plaster that plaster application can work

to, to eliminate cold joints ·

A2.1.3 Weather-exposed SMJS lath accessories and

casing bead lath accessories at stucco panel edges must be sealed to prevent

bulk water intrusion ·

A2.3.1 Requirements for “control joints” and

perimeter relief, are referenced to ASTM C1063. Solid plaster bases do not require stucco

movement joints, except at expansion joints occur. ·

A2.3.1.1 Remove plaster from “control joints” from

the pleat before plaster hardens. ·

A2.3.1.2 Install “control joints” before applying of

plaster. Determine their type,

location, depth, and method of installation by the characteristics of the

substrate and indicate requirements in the contract documents. ·

A2.3.1.3 A groove or cut in plaster is not a

“control joint”. ·

A2.3.3 Where plaster is applied continuously over

dissimilar base materials, provide…casing beads back-to-back, or a “control

joint” From ASTM C1007 we note: ·

7.1 Steel stud framing must be plumb within 1⁄8 in. in

10 ft. ·

A2.4 Steel studs must be allowed for at …“control joints”, etc. From ASTM C1063 we note: ·

3.2.3 A “control joint” is a joint that accommodates

shrinkage and curing movement, usually as straight lines. ·

7.5.4 At

suspended ceiling grillage, main runners must allow “control joint” movement. ·

7.6.5 At suspended ceiling grillage, main runners

and cross furring must allow “control joint” movement ·

7.10.1.5 Lath must be discontinuous through “control joints” and fastened

to substrate support at each side. ·

7.11.4 “Control Joints” are

a one-piece prefabricated member or paired casing beads back to back with SAF

behind the casing beads. Provide a 1⁄8

in. minimum gap. ·

7.11.4.1 Provide “control joints” at defining panel areas

at walls not exceeding 144 SF, and at ceiling areas not exceeding 100 SF. ·

7.11.4.2 The

maximum panel dimension between “control joints” is 18 ft

or a panel area length-to-width ratio of 21⁄2 to 1. Provide a “control

joint” where ceiling framing or furring changes direction. ·

7.11.4.4 Wall or

partition height door frames are “control joints”. ·

A1.2 “Control Joints” accommodate stucco curing and drying shrinkage movement,

along usually straight lines and function as a screed to aid in stucco

thickness control. From ASTM C1280 we note: ·

8.2.1.1 Gypsum sheathing panel corners must be notched a

minimum of 4-in. at window, door and similar wall opening

corners. Today’s Minimum Stucco Industry Standards ASTM C926 and ASTM C1063,

describe various general prescriptive requirements on what a SMJS is, how it

is configured, and on where to locate the SMJS on a building where it is

intended to minimize stucco cracking by accommodating portland cement-based

plaster shrinkage and stucco thermal movements. |

||||||||||||||||||||||||||||||||||||||||

|

GENERAL Since the mid-1950s, the stucco panel

isolation joint has been termed the “control joint,” however this website

preferentially uses the term Shrinkage Movement Joint Subassembly (SMJS) and

SMJS lath accessory. The one-piece

SMJS lath accessory is used in a SMJS subassembly which includes the

substrate support (continuous), the configuration of the lath

(discontinuous), framing/blocking to receive lath edge fasteners, the SMJS

lath accessory and its fasteners, and of course the portland cement-based

plaster. Clark’s

SMJS requirements: Clark designed and

patented the SMJS lath accessory to be wire-tied to the outer face of

continuous “expansible” lath and not fastened with nails, screws or staples

to the substrate support framing or blocking.

Throughout the patent documentation, the SMJS lath accessory is

clearly described to be a flexible extension to allow concentrated movement

within the lath, and is isolated from and not connected to the substrate

support framing or blocking. For movement to occur Clark clearly describes

and states throughout the patent that the lathing was “expansible” which he

appears to have assumed was capable of expanding and contracting according to

the movement needs imposed upon the SMJS by portland cement-based plaster

shrinkage movement and stucco thermal movement. A SMJS is part of the lath and

stucco composite wall cladding assembly only, and is isolated and not part of

the continuous substrate support.

Mechanically fastening the SMJS lath accessory to the continuous

substrate support framing or blocking with nails, screws or staples makes it

physically attached to and part of the substrate support which significantly

reduces its ability to accommodate shrinkage and thermal movements, and

minimize cracking. As

it turns out, and contrary to the depictions and assumptions in Clarks

patent, as proven by performance testing, where the lath is continuous

through the SMJS, metallic lath in any of its forms, expanded sheet metal,

woven wire or welded wire, is not expansible enough to accommodate the amount

of dimensional movement SMJS are subjected to, capable of, or required to

accommodate to minimize cracking. ASTM

C1063 recognizes this materials property characteristic of lath products and

requires the lath to be discontinuous at SMJS to minimize the restriction of

lath continuity to movement at the SMJS and mitigate its ‘non-expansibility’

characteristic, to allow movement and minimize cracking. The requirement for

discontinuous lath at SMJS in Minimum Stucco Industry Standards has not

changed since it was first introduced in the 1971 ANSI A42.3(6). The subject of stucco “control joints” was

something I had to wade through myself and this webpage is a summary of the

highlights from that journey. First

and foremost, I decided from the onset to have an open mind and was committed

to locate and consider all information and evidence available and not

approach this subject with any predispositions or preconceptions, in a

comprehensive, considered and rational manner. I have been interested from the earliest

days of my professional career (mid-1980’s) about all things related to

stucco, and “control joints” is central to that interest. I set out to locate and evaluate every bit

of information available about stucco “control joints” that I could find, and

a number of significant, meaningful, informational and related resources that

had been forgotten about or overlooked through time, have surfaced and been

brought together here, for the first time together in one place – for careful

re-evaluation and to illuminate a progressive context to understand the

broader perspective. Don’t shoot the

messenger – it is what it is! While we

can develop conclusions and suggestions going forward, they should be based

on the broad spectrum of complete information, evaluated collectively, which

considers a thorough review of all information resources available on the

subject. It is too easy to cherry-pick

information that may support one position or another and what a tremendous

disservice that is to gaining a complete understanding of “control

joints”. The conclusions and

suggestions presented are based on the considerations of rational inquiry, on

laboratory performance testing, on material properties and characteristics,

on the realities of construction document and jobsite-related challenges, on

observations of stucco cladding systems and their components, behavior and

performance of different SMJS configurations since the mid-1980’s, from the

perspective of a technically-oriented architect. When evaluating the various available

resources, conflicts, misinformation, incomplete information and other

conditions may at first be problematic.

Use professional discernment, and disregard unsubstantiated

information. The hope is that the reader

will consider approaching this topic with the same rigor as together we seek

a unified industry voice on this very important subject. The

Minimum Stucco Industry Standards regarding SMJS provide limited but

important and useful basic, prescriptive-based criteria. The specific Minimum Stucco Standards of

Care for SMJS are defined in the building code which includes adopted

reference standards ASTM C926 and C1063.

Because these are the only applicable codified references, other

stucco industry references, where they conflict with ASTM C926 and C1063 may

result in SMJS that do not comply with the building code and result in less

than minimally acceptable stucco performance.

Following manufacturers written requirements for their prefabricated

SMJS lath accessory products is also a Minimum Stucco Standard of Care. Discussion: Terminology: “Control Joint” vs. Shrinkage Movement

Joint (SMJS) Subassembly That term “control joint” is a significant part of

the struggle the industry has experienced through the decades because it is

impossible to know or understand intuitively exactly what the “control joint”

controls, or to understand if it is a dynamic or static joint, from its name

alone. The term is also vague as to

what it is in reference to, and has been commonly and incorrectly used to

describe merely the lath accessory, and not a functioning stucco movement

joint as a subassembly of various components working together. Complicating things, for decades this term

was also used interchangeably throughout the industry, by the lath accessory

manufacturers, and in ASTM C1063 with the term “expansion joint”,

“stress-relief joint”, “expansion/contraction joint” and other similar and

vague terms, without a clear understanding of what exactly was expanding (the

joint, the stucco, or the substrate?), and even sometimes used to describe

decorative joints such as formed grooves, cuts and reveals. What is abundantly clear is that the

“control joint” lath accessory has been promoted and used since its

introduction without a definitive understanding of its purpose, intended and

actual function, intended and actual performance, or intended and actual

installation requirements to achieve its functions, all of which have seemingly

mutated into multiple variations over time. The term “control joint” is unfortunately too

generic, broad, nebulous, ambiguous, and obscure to have any real, intuitive

or commonly accepted meaning – which in part has merely just fueled the fire

of dissension in the stucco industry.

The term “control joint” has not served us well, is obsolete and does

not clearly describe that this is a subassembly of the larger stucco wall

cladding system, which includes adjacent components within the subassembly,

arranged in a specific configuration for performance reasons, and is not just

a lath accessory component, and it does not describe the purpose or function

of this stucco movement joint subassembly.

We as the stucco industry would be well-served to abandon the term

“control joint” from our vocabulary because it is vague and replace it with a

more accurate, clearly understood, descriptive term. Where the term “control joint” is used on

this website, it will be surrounded by quotes in respect of its common or historic

contextual usage, and will only be used in homage to its original context. ASTM C1063 added clarity, definition and

distinction to the two terms “control joint” and “expansion joint” in

2007. These two different stucco

movement joint subassembly categories are not the same; they are different in

many physical, installation and functional characteristics. In ASTM parlance, a “control joint” is

intended to accommodate portland cement-based plaster shrinkage and stucco

thermal movements, and an “expansion joint” is to accommodate building

substrate support movements. In search of clarity I derived what I suggest is a

more accurate descriptive term for “control joint”. The term Shrinkage Movement Joint

Subassembly (SMJS) as used on this website is used for easier, more intuitive

recognition, to promote understanding, to facilitate its effective use and

because it more clearly describes the purpose and function of this stucco

cladding movement joint subassembly. The term Shrinkage Movement Joint lath accessory is used to describe just the lath

accessory component where that is appropriate for the context. Because the subassembly and lath accessory

are directed at accommodated shrinkage and thermal movements, the term could

have been “shrinkage and thermal movement joint”, but since thermal movements

impart similar behaviors as shrinkage movements but at much smaller

magnitudes, it is reasonable to shorten the name to just Shrinkage Movement

Joint Subassembly (SMJS), for

simplicity. The term SMJS

is the complete term for the subassembly and the term SMJS lath accessory is

the complete term for the SMJS lath accessory component. These terms are not interchangeable because

they mean different things, and neither of these terms should be shortened to

simply “SMJS”, because the term SMJS is incomplete and could cause

misunderstanding and miscommunication.

The intention of this key point about clarity of terminology is to

avoid the potential misperception, confusion and miscommunication that may

occur, which has occurred with use of the term “control joint”, in that the

duality and unclarity of meaning that the term SMJS

could be in reference to either a lath accessory or a subassembly. The term SMJS is not used in the building code or Minimum Stucco

Industry Standards, where it is generically described as a stucco “control

joint” and the term SMJS lath accessory is not used by any known lath

accessory manufacturers. Discussion: Portland Cement-based Plaster and Stucco

Movements Portland cement-based plaster shrinkage movement during curing and

stucco thermal movements while in service are significant factors that are a

primary cause of stucco cracking, most will agree. While shrinkage and thermal movements are

important, it is recognized that other factors can contribute to stucco

cracking also so addressing merely shrinkage and thermal movements alone, are

not the only factors contributing to stucco cracking, but they are primary

considerations substantiating the use of SMJS. This webpage focuses primarily on the issue

of portland cement-based plaster shrinkage movement and stucco thermal

movement and a primary method of utilizing the SMJS to minimize their contributory

effects regarding stucco cracking. The SMJS developed from the Perimeter Movement Joint Subassembly (PMJS),

so a complete understanding of the principles and context presented on the

PMJS subassembly webpage and Stucco Material Properties webpage is

fundamental to an understanding of SMJS along with the additional information

specific to SMJS presented on this webpage. The stucco SMJS by definition in ASTM

C1063 is: “3.2.3 control joint, n—a joint that accommodates

movement of plaster shrinkage and curing along predetermined, usually straight,

lines. Note that this definition does

not specifically identify stucco thermal movement while in service. Thermal movements are mentioned in ASTM

C1063 at 7.11.4 where it says: “Control joints shall be formed by using a single

prefabricated member or fabricated by installing casing beads back to back …

The separation spacing shall be not less than 1⁄8 in. (3.2 mm) or as

required by the anticipated thermal exposure range.” Thermal-related

materials expansion or contraction movements in stucco are identical in

behavior to shrinkage of portland cement-based plaster, just of a much

smaller magnitude than shrinkage movements.

Because of their similar behaviors, the two movements can be considered

as additive together for purposes of evaluating SMJS movement behavior as

long as their individual magnitudes are understood and accommodated. Stucco

behaves differently when installed on framed or framed/sheathed substrate

supports than when directly-applied and continuously-bonded to a solid

substrate support. Where

directly-applied to mass masonry and solid concrete mass wall substrates

without a WRB, stucco cladding is continuously-bonded and therefore

continuously-restrained from movement caused by shrinkage and thermal

movement as a result of its continuous bond to the masonry or concrete

substrate support. Cracking occurring

where directly-applied is typically translational cracking from localized

movement in the substrate support, or is the result of movements at discrete

locations where the stucco is not continuously-bonded to (delaminated from)

the substrate support. As a result,

SMJS serve no purpose for directly-applied stucco on masonry or concrete

walls, in addressing portland cement-based plaster shrinkage or stucco

thermal movements. Portland

cement-based plaster installed over lath creates a new homogenous lath and

stucco composite material possessing the newly combined properties of both

materials. Portland cement-based

plaster installed on framed substrate supports over lath and a

water-resistive barrier is not continuously-bonded to the substrate support

and dynamically shrinks, expands and contracts relatively independently from

its substrate support – it is conceptually isolated perhaps, but is not a

complete isolation. The lath is

mechanically fastened to the substrate support at periodic intervals which

inherently restricts movement of the plaster or stucco membrane at each lath

fastener attachment location, yet allows shrinkage and thermal movement

independent of the substrate between the mechanical fasteners. Lath fasteners such as nails, screws and

staples used to mechanically fasten lath to the substrate support can be a

restriction to shrinkage and thermal movement in the field of a stucco panel,

but a restrictive condition at lath fasteners is not absolute and depends on

the conditions at a specific fastener location. For example, where the lath fastener head

is not drawn tight to the substrate support surface, limited slippage can

occur between the lath fastener head and the lath to allow limited

movement. Or when the lath fastener

head is drawn tight to the lath and substrate support, fasteners at

self-furred points or even in the field of the lath, may draw the lath to the

rearmost plane of the stucco, and the stucco immediately proximate to the

lath fastener may not embed the lath.

The localized unembedded lath has been observed to distort around lath

fasteners in this configuration to allow limited movement, similar to what

has been observed to occur proximate to lath edge fasteners at SMJS. A lath fastener that could be devised to

allow a greater degree of predictable shrinkage and thermal movement for the

field of the lath would be beneficial in minimizing stucco cracking.

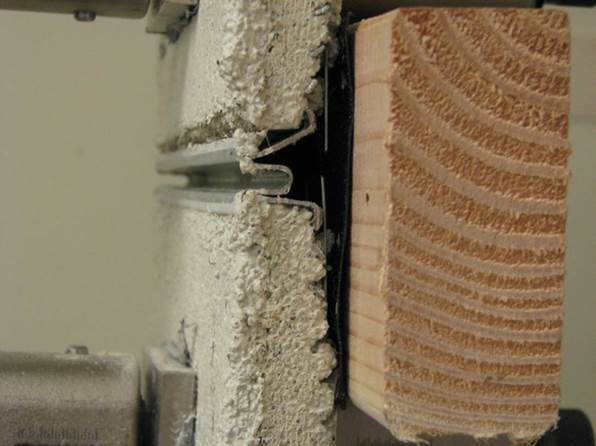

Lath not embedded proximate to lath fastener can

allow limited movement by slippage or lath strand distortion around lath

fastener. (Lath fastener removed, but imprint visible in

stucco behind lath) The

process and duration of stucco mortar curing involves water loss and

compositional changes in the mortar that result in both strength increase and

volumetric reduction or shrinkage of the stucco mortar. The curing rate, and related shrinkage

movement amount is discussed in more detail elsewhere on this website, but

summarized here. The

combined shrinkage and thermal movements from ambient temperature variations

for design purposes is in the approximate range of 130-240 mils for each 10

feet (13-24 mils per lineal foot) of stucco over a 100 degree F temperature

range. While this may seem small

dimensionally, it is a significant amount of movement for portland cement-based

plaster while in its plastic state, and for stucco as a dense, brittle

material where movement can cause cracking if not accommodated. To determine which stucco movement joint is

appropriate for a given condition, one must understand the differences in anticipated

movement at a given condition.

Shrinkage and thermal movements occur in the composite lath and stucco

membrane. BMJS, PMJS and SMJS each

accommodate shrinkage and thermal movements because the composite lath and

stucco membrane is discontinuous through and terminates

at each edge of these subassemblies. A

SMJS is not intended to accommodate substrate support movement both by

definition and because the substrate support is continuous at SMJS. BMJS and PMJS accommodate substrate support

movement by their definitions and because the substrate support is

discontinuous and each side of the BMJS and PMJS and their substrate supports

can move independently. Discussion: Purpose of the SMJS Subassembly Shrinkage Movement Joint Subassemblies (SMJS) serve these purposes: ·

1st Purpose: Accommodates portland cement-based plaster

shrinkage movement occurring soon after plaster application, and stucco

thermal movement after the plaster has cured, resulting from daily and

seasonal thermal expansion and contraction, by using a flexible portion and

extension of the lath created by discontinuous lath and a flexible SMJS lath

accessory in the plane of the lath, mounted to the lath only and not the

substrate support. ·

2nd Purpose: As a ground screed to gauge the application

thickness of portland cement-based plaster to assist in the achievement of

its intended nominal thickness and finish planarity. ·

3rd Purpose: Segments and panelizes continuous stucco

wall cladding assemblies into functionally isolated, discrete, smaller,

adjacent wall cladding panel areas with panel edges that define portland

cement-based plaster work stoppage locations and prevent cold joints. 1st Purpose: Shrinkage Movement

Joint Subassemblies (SMJS) are generally perceived as a complex,

misunderstood and hotly-debated subassembly in the stucco industry, but it

does not need to be that way.

Throughout the industry we have made the topic of SMJS much more

difficult than it needs to be, if collectively we can recognize, understand,

and agree on a few inherent stucco movement characteristics. It is not surprising that the complexity

surrounding the characteristics, requirements and expectations for SMJS has

caused misunderstandings, misinformation, insufficient design, insufficient

installation, insufficient inspection and ultimately less than reasonable

quality stucco performance as manifested by excessive cracking, water

intrusion and other stucco and SMJS performance-related issues. Fundamentally, most people will agree that it is an

intrinsic characteristic of portland cement-based plaster to shrink as it

cures and hardens, because it contains water that evaporates or is consumed

in the process of curing causing volume loss, and is applied in a wet,

plastic state, unlike most other contemporary exterior wall cladding

materials. Portland cement-based

plaster shrinkage is a one-time event that only occurs subsequent to

application of the wet plaster. If

portland cement-based plaster shrinkage did not occur and cause cracking,

then the stucco SMJS would not be necessary to accommodate shrinkage, or at

least the accommodation of shrinkage movement would not be of concern. The other type of movement the SMJS

accommodates is stucco thermal expansion and contraction after the stucco has

cured and hardened; a behavior that occurs cyclically on daily and seasonal

intervals, throughout the service life of stucco. The dimensional movement related to stucco

thermal expansion and contraction behavior is of comparatively minor

magnitude relative to stucco shrinkage movement, but similar in dynamics, and

because thermal movements are minor and similar, its effects are considered

in parallel along with shrinkage because the movement dynamics are similar,

if unequal but complementary in magnitude.

The essential point to comprehend about SMJS is that without an

appreciation for and understanding of the basic behavior and characteristics

of portland cement-based plaster shrinkage and stucco thermal movement, one

cannot expect to appreciate or understand the design, function and

installation requirements of the SMJS and the role it performs towards

minimizing stucco cracking. We need to

agree on the basic functional requirements of SMJS before proceeding, because

they are based upon the shrinkage and thermal movement-related behavior of

portland cement-based plaster and stucco. Stucco

cracking in general terms is an inherent characteristic of stucco, not a

defect in and of themselves but they may be the manifestation of other

defects, latent or patent. Cracking

are generally the manifestation of unaccommodated stresses within the portland

cement-based plaster or stucco membrane and are not only a visual distraction

but they may also allow water intrusion.

Generally, cracking are not considered to be defects, unless they are

part of a larger context of causes or contribute to resultant damage such as

water intrusion and/or building substrate support deterioration. SMJS correctly designed, located and

installed may assist in minimizing the most common types and occurrences of

stucco cracking which is related to initial portland cement-based plaster

shrinkage and stucco thermal movements. In

the broadest sense and by definition, an SMJS is a “joint that accommodates

movement of stucco shrinkage and curing along predetermined, usually

straight, lines”. These comparatively

small magnitude movements occur primarily in the portland cement-based

plaster membrane and if not accommodated, can result in stucco cracking. SMJS may

also assist in minimizing stucco cracking from the contributory effects of

other ancillary, induced, cement plaster and stucco stresses, which are not

substrate support-related, and which are in addition to and may exacerbate

cement plaster shrinkage and stucco thermal movements. These concentrated stresses may include

stucco membrane thickness variations resulting from wrinkly building paper,

stresses proximate to the expansion and contraction of wood-based sheathings

while in service and stresses related to lathing anomalies. SMJS,

BMJS and PMJS individually exist for the sole purpose of managing portland

cement-based plaster and stucco movement in different conditions, to minimize

stucco cracking. However each of these

stucco movement joint subassemblies functions similarly to the SMJS to manage

portland cement-based plaster shrinkage and stucco thermal movements, because

the lath is discontinuous and terminates at these stucco movement joint

subassemblies. From

ASTM C926 we read “…control joints and expansion

joint[s]…shall be installed prior to the application of plaster. Their type, location, depth, and method of installation shall

be determined by the characteristics of the substrate and included in the

project contract documents.”

Underlining is by this author for emphasis. This text is broadly worded determining

criteria for deciding whether a SMJS, BMJS or PMJS is required and is often

overlooked. It can mean that if there

is no movement within the substrate support to accommodate (where the

substrate support is continuous), the primary movement that does occur is

portland cement-based plaster shrinkage and stucco thermal movement only, and

the appropriate stucco movement joint subassembly is an SMJS. If the building substrate support is

discontinuous at a stucco movement joint location, then the more significant

movement is substrate support movement, and the appropriate stucco movement

joint is a BMJS if along a wall or PMJS if at an internal corner. Effective utilization of a SMJS is no guarantee against stucco

cracking. SMJS are only one of several

elements in a complete stucco wall cladding system that may be useful towards

minimizing cracking – mix design, aggregate selection and gradation, fiber

admixtures, lath type, finish type and texture, workmanship, curing, and many

other factors – all have a contributing role towards either contributing to

or minimizing cracking. SMJS are not complicated if one

understands why they are needed, how they function and where best to locate

them. It is a fundamental